TC6518型塔机回转系统设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

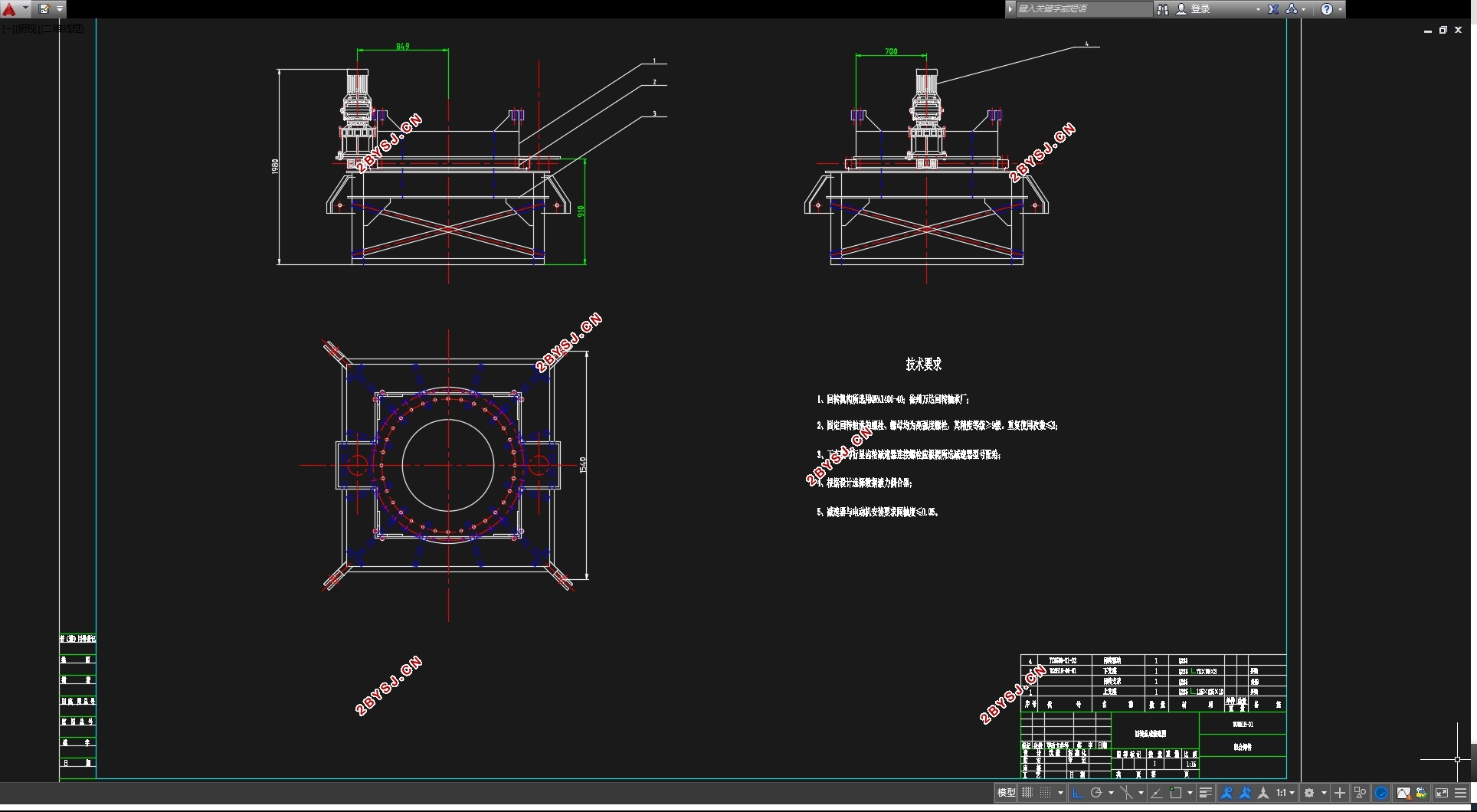

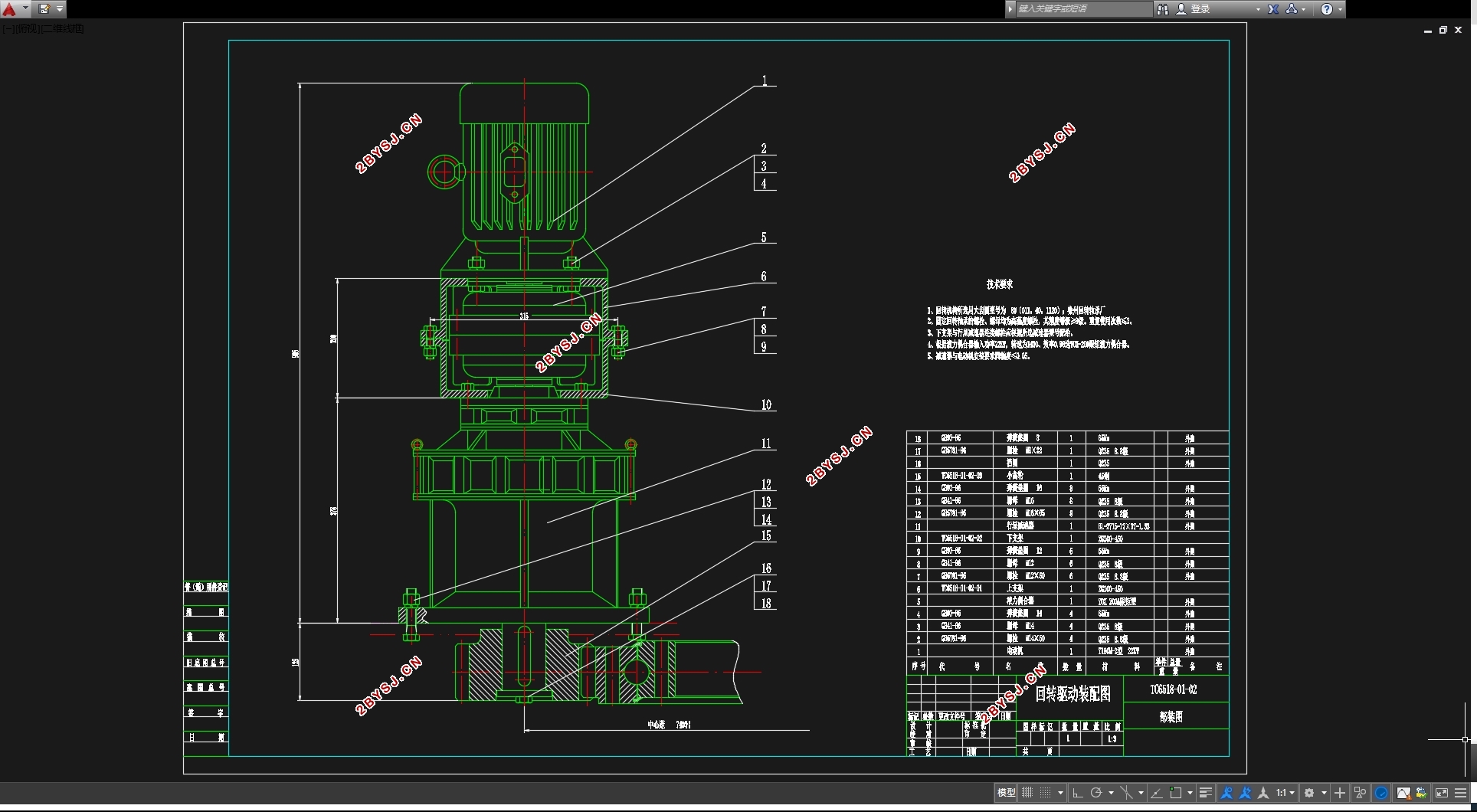

TC6518型塔机回转系统设计(含CAD零件图装配图)(任务书,开题报告,论文说明书9000字,CAD图6张)

摘 要

塔式起重机是现代工业建设中广泛使用一种起重机械,塔机的整个回转系统在塔机中起着中枢连接的重要的作用。这对回转系统设计提出了严格的要求。

本篇文章,首先对塔式起重机国内外研究状况作了介绍;并对塔机回转系统中回转支承和回转驱动装置进行了概述;然后通过对TC6518型塔机的回转支承装置进行受力分析计算,得到了回转支承所受的垂直力V,水平力H和力矩M。基于回转支承所受的垂直力V,水平力H和力矩M,选择了单排四点接触式回转支承型号为01系列外齿式011.40.1120。通过计算回转支承所受回转阻力矩,求出电机的等效功率选择YZR200L-6型号的电机,并进行发热和过载校核,验证了所选电机满足要求。根据所选电机额定功率选配yo×320型限矩型的液力耦合器。确定行星齿轮减速器的减速比分配选择XX4-100-195型行星齿轮减速器。另外本文还对塔顶进行了设计,通过分析计算重物在起重臂头部重物在起重臂中心,重物在起重臂根部三种工况下塔顶所受的轴力和合力矩,选择最危险的工况即塔顶所受合力矩最大,验证塔顶整体稳定性和单肢稳定性。完成设计。

关键词: 塔式起重机 回转支承 塔顶 稳定性

Design of Turning System for TC6518 Tower Crane

ABSTRACT

Tower crane is widely used in modern industrial construction. The whole slewing system of tower crane plays an important role in the central connection of tower crane. This puts forward strict requirements for the design of rotary system.

This paper first introduces the research about tower cranes at home and abroad. It also gives an overview of the slewing bearing and slewing drive in the tower crane slewing system. Then, through the calculation of the slewing bearing of the TC6518 tower crane, the slewing bearing is obtained. The vertical force V, the horizontal force H and the moment M. Based on the vertical force V received by the slewing ring, the horizontal force H and the moment M select a single-row four-point contact slewing type 01 series external gear type 011.40.1120. By calculating the rotational resistance torque of the slewing bearing, the equivalent power of the motor is selected to select the motor of the YZR200L-6 model, and the heating and overload check are performed to verify that the selected motor meets the requirements. The yo×320 type torque limiting type fluid coupling is selected according to the rated power of the selected motor. Determine the reduction ratio of reducer to select the XX4-100-195 gear reducer. In addition, I also designed the top of tower.Through analysis,we can calculate the axial force and resultant moment on the top of the tower under three working condion toselectthe most dangerous working condition, that is, the maximum torque of the top of the tower, and verify the overall stability of the tower top and the stability of the single limb. Finish the design

Keywords: tower crane ; slewing bearing; tower top

目录

摘 要 Ⅰ

ABSTRACT Ⅱ

第一章 绪 论 1

1.1选题意义和目的 1

1.2 塔式起重机在国内外相关发展情况 2

1.3本文研究内容 2

第二章 回转机构 4

2.1回转机构的组成 4

2.2回转支承分类及选型 4

2.3回转支承安装关系 5

2.3.1回转总成之间连接关系 5

2.3.2塔顶与回转机构的连接关系 5

2.4回转驱动装置 6

第三章 回转系统设计 8

3.1设计要求 8

3.1.1塔机的主要参数 8

3.1.2 起重机的工作级别 8

3.1.3机构的工作级别 9

3.2回转支承的受力计算 9

3.3回转阻力矩的计算 11

3.4驱动电机的选择与校核 15

3.5液力耦合器及减速器的选用 16

3.5.1 液力耦合器的选择 16

3.5.2减速器的选择 17

第四章 塔顶设计 19

4.1塔顶结构及基本参数 19

4.2作用在塔顶上的载荷计算 20

4.2.1 载荷计算 20

4.2.2载荷的合成和力矩的合成 23

4.3塔顶校核 25

4.3.1塔顶整体稳定性验算 26

4.3.2单肢稳定性验算 28

4.4塔顶销轴连接计算 30

第五章 总结与展望 32

5.1经济性分析 32

5.2总结与展望 32

参考文献 34

致 谢 36