汽车变速箱机油泵体的铸造工艺设计及仿真分析(含CAD图,UG三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

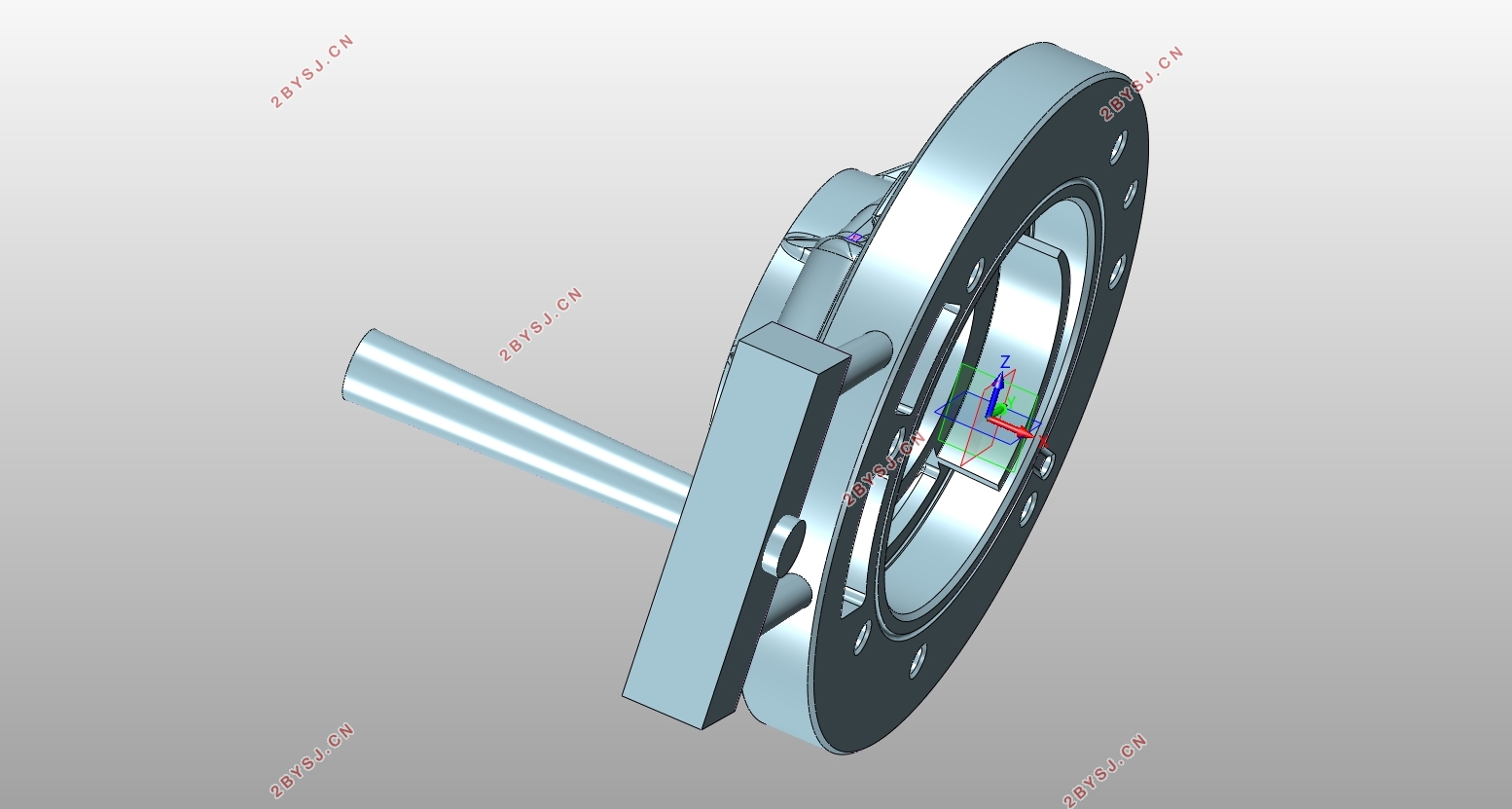

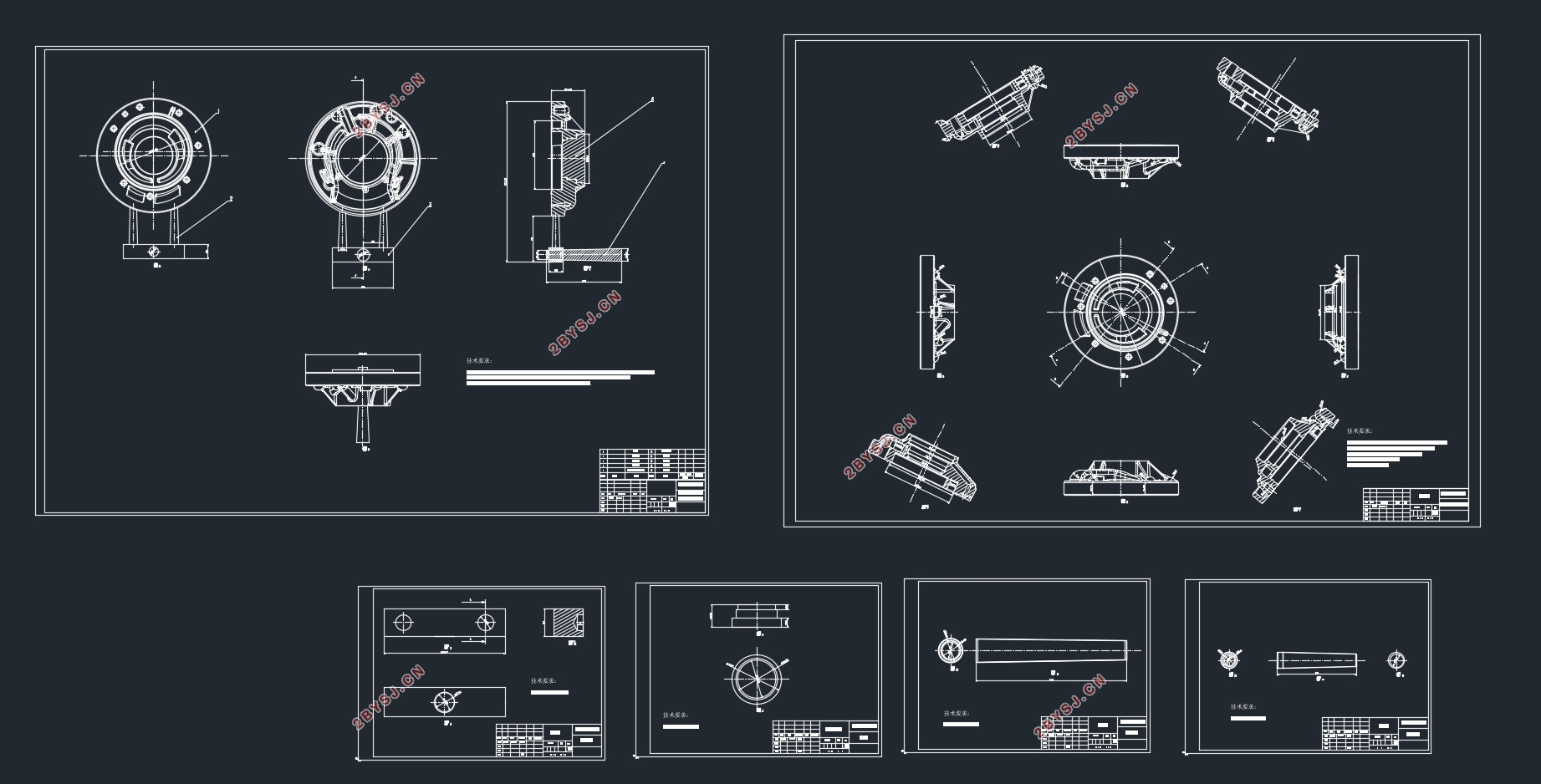

汽车变速箱机油泵体的铸造工艺设计及仿真分析(含CAD图,UG三维图)(任务书,开题报告,文献摘要,外文翻译,论文说明书16000字,CAD图6张,UG三维图)

摘要

尽管汽车零件毛坯成形的方式有很多,但是对于缸体、缸盖、机油泵体等形状结构复杂的零部件则必须采用铸造工艺加工。这使得铸造在汽车工业中占有十分重要的地位。随着计算机技术的发展应用,CAD/CAE技术不断应用到工程制造上,铸造过程的数值模拟技术日益成熟,为铸造技术轻量化、精确化、数字化发展做出了巨大贡献。铸造过程数值模拟仿真技术能够对铸件的充型和凝固过程进行模拟,预测出诸如缩松、缩孔、冷隔、夹渣等产品缺陷位置,从而优化相关工艺过程,提高产品质量,降低生产成本。

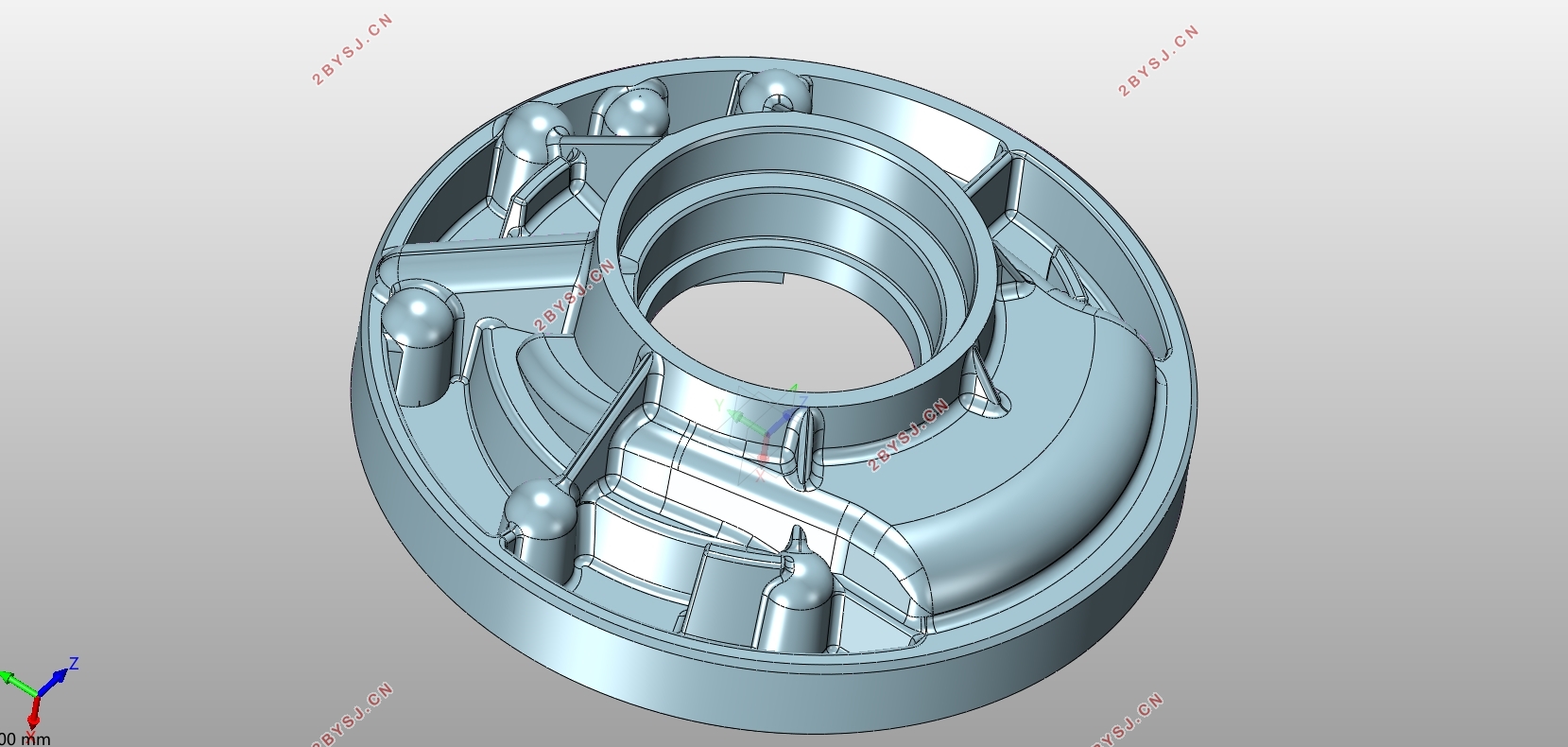

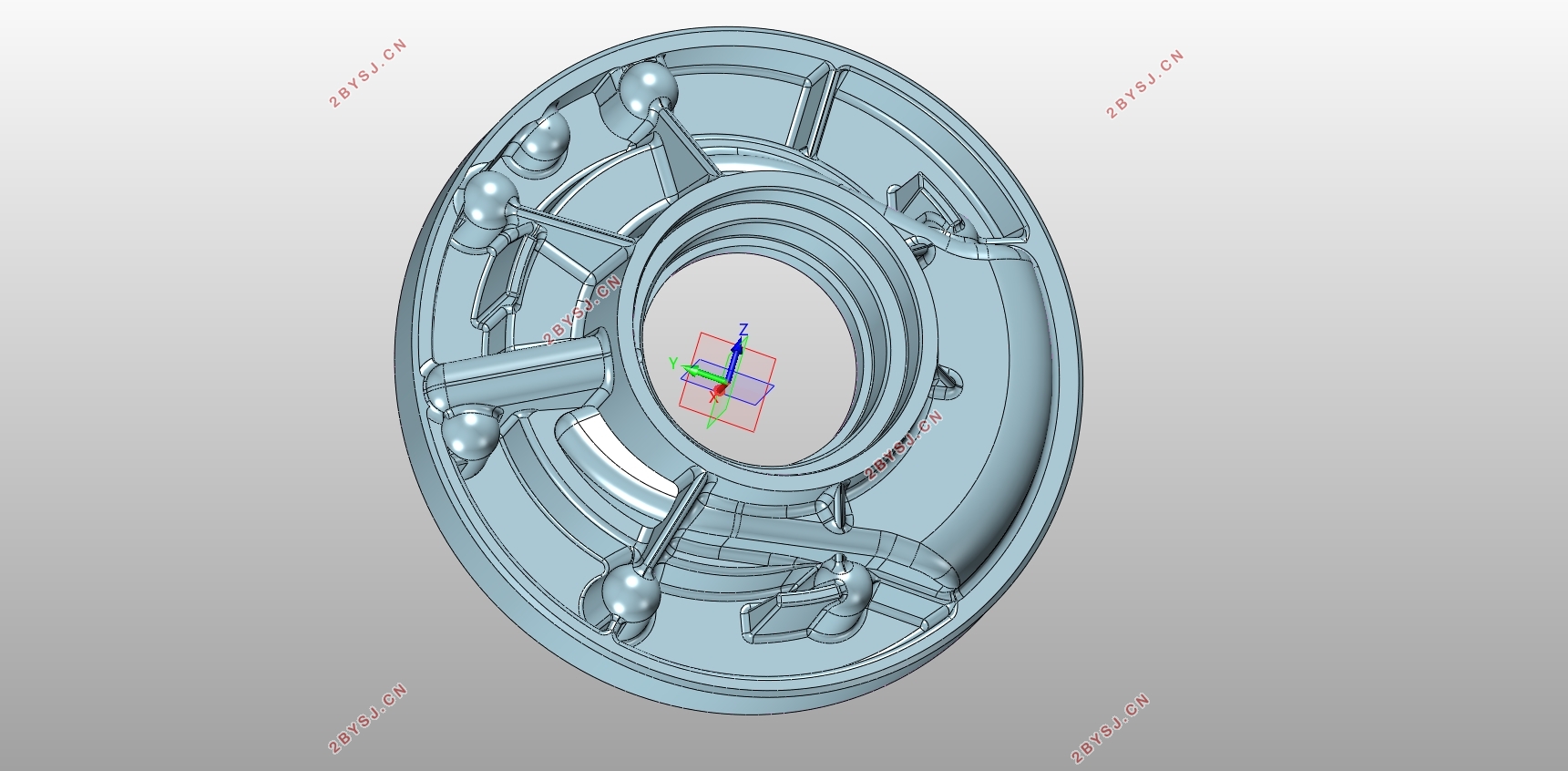

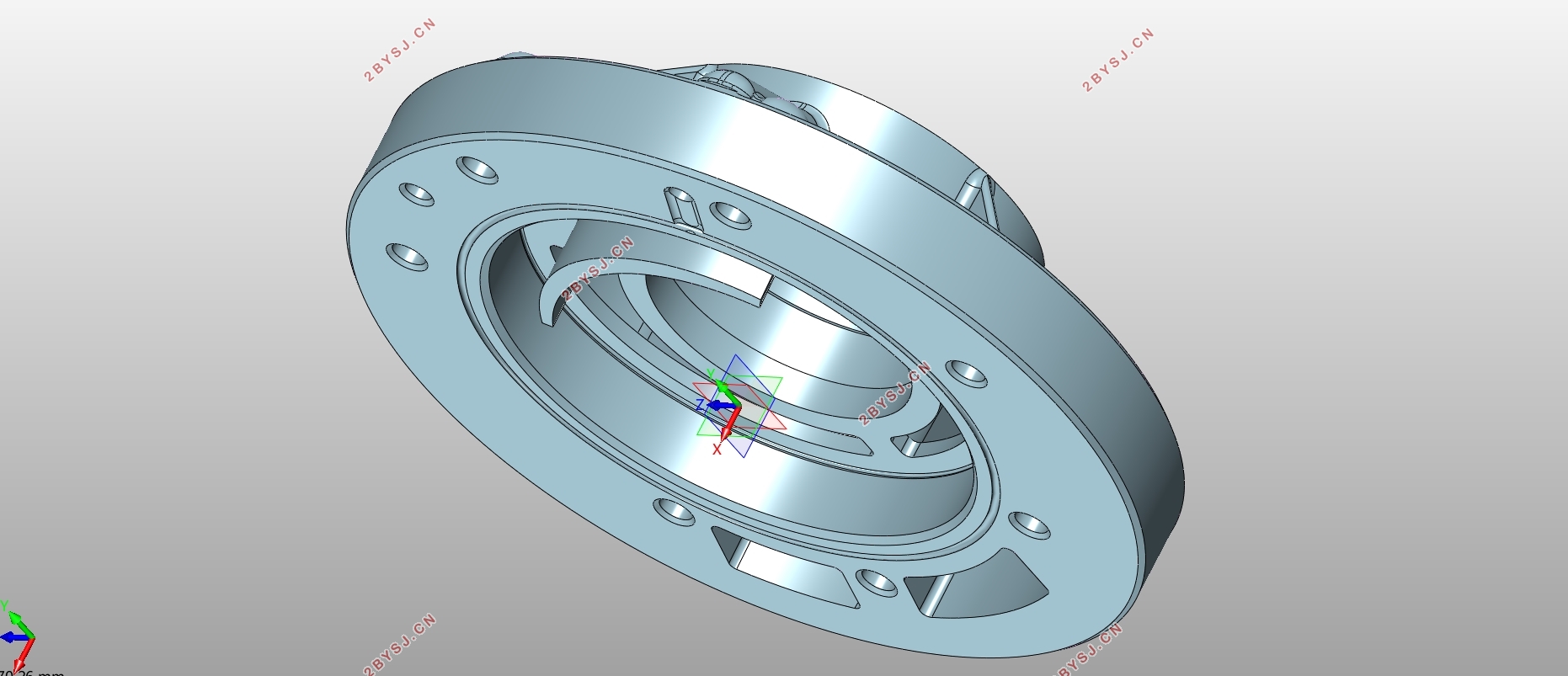

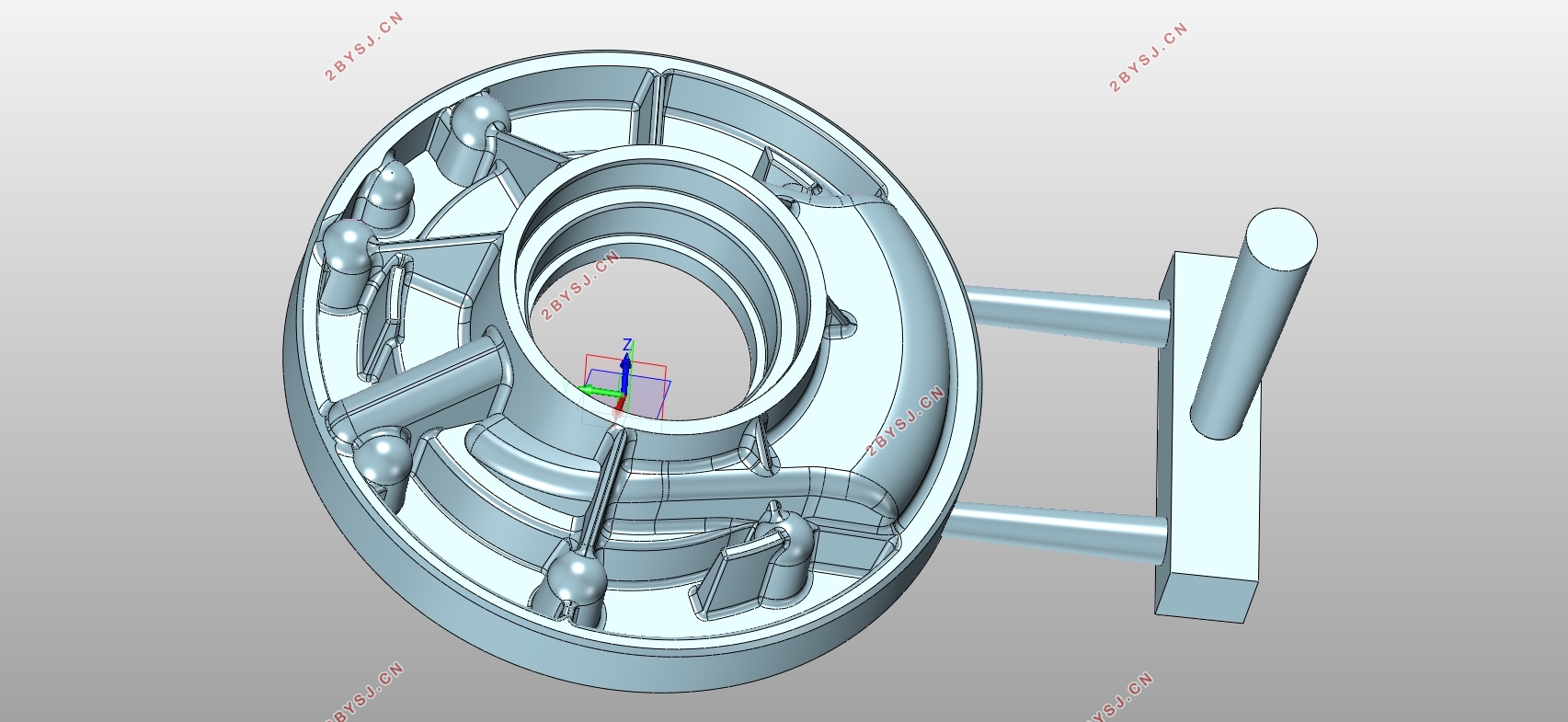

本文依据某公司变速箱机油泵体结构较复杂、局部位置壁厚大内部易产生缩松、缩孔等缺陷的问题设计了合理的铸造工艺方案。首先通过分析铸件工艺性能并对比各种铸造方式的特点,选择了对变速箱机油泵体来说最为合适的砂型铸造工艺,也确定了浇注位置和分型面;然后通过计算设计了浇注系统中横浇道、直浇道和内浇道的尺寸,并使用UG三维制图软件进行三维建模;接下来借助铸造CAE软件AnyCasting对该工艺进行充型凝固过程模拟实验,根据所产生的缺陷情况作出了相关的工艺完善。最后对完善后的工艺过程进行模拟分析得到了更为理想的仿真结果,证实了完善方案的有效性,以供实际的生产过程的借鉴与参考。

关键词:铸造技术、机油泵体、工艺设计、数值模拟

Abstract

Although the auto parts blank forming a lot of way but for the cylinder, cylinder head, oil pump body and other complex structure of the parts must be manufactured by casting process,Which makes casting occupy a very important position in the automotive industry.With the development and application of computer technology, CAD / CAE technology has been applied to engineering manufacturing. The numerical simulation technology of casting process has become more and more mature, making great contributions to the development of metering technology, standardization and digital development.The numerical simulation of casting process can simulate the filling and solidification process of the casting, and predict the defect location such as shrinkage, shrinkage, cold separation, slag and so on, so as to optimize the related process, improve the product quality and reduce the production cost.

This paper designs a reasonable casting process according to the problem that the structure of the oil pump body of a company gearbox is more complicated and the local wall thickness is large. First of all, by analyzing the casting process performance and comparing the characteristics of various casting methods, the most suitable sand casting technology for the gearbox of the gearbox is selected, and the pouring position and the parting surface are determined. Then, the casting system which includes the size of the sprue,the runner and the gate is designed by calculation. and use the UG 3D mapping software to carry out the three-dimensional modeling; then the casting CAE software AnyCasting the process of filling the solidification process simulation experiment, according to the resulting defect The relevant process perfect. Finally, the simulation results of the improved process are obtained, which is proved to be effective and effective for the practical production process. First of all, by analyzing the casting process performance and comparing the characteristics of various casting methods, the most suitable sand casting technology for the gearbox of the gearbox is selected, and the pouring position and the parting surface are determined. Then, the casting system which includes the sprue, the runner and the gate is designed by calculation, andthe UG which is a 3D mapping software was used to carry out the three-dimensional modeling; Next, the simulation experiment about casting process and solidification process were carried out by means of casting CAE software AnyCasting, and the related process was perfected according to the situation about defects. Finally, the simulation results of the improved process are obtained, which is proved to be effective and effective for the practical production process.

Key Words:Casting technology; Oil pump body; Process design; Numerical simulation

目录

目录 I

第1章 绪论 1

1.1课题研究的背景及意义 1

1.1.1汽车变速箱机油泵体 1

1.1.2材料成形技术 1

1.1.3砂型铸造的优势 2

1.1.4数值模拟技术的作用 2

1.2国内外研究现状 3

1.2.1砂型铸造的发展现状与趋势 3

1.2.2 铸造模拟仿真技术的发展现状与趋势 3

1.3课题研究内容与目标 4

第2章 汽车变速箱机油泵体铸造工艺设计 6

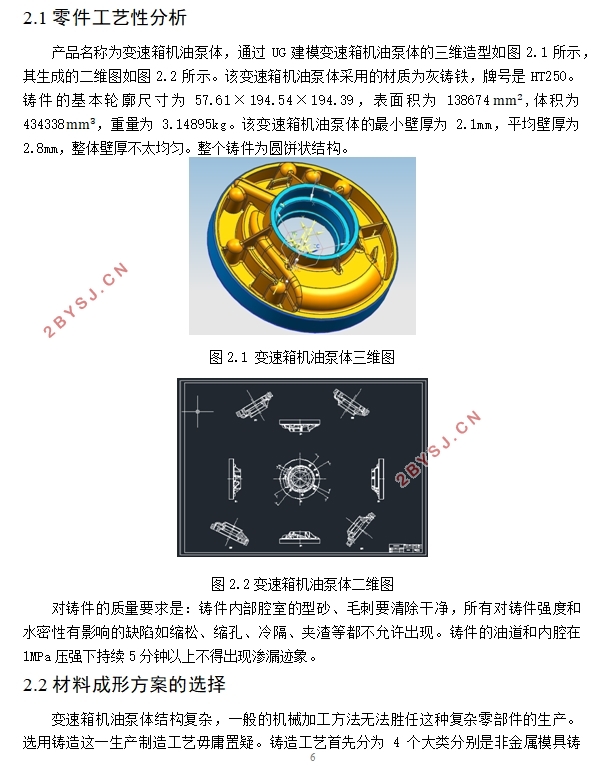

2.1零件工艺性分析 6

2.2材料成形方案的选择 7

2.2.1非金属模具铸造工艺 7

2.2.2金属模具制造工艺 7

2.2.3压力型铸造工艺 8

2.2.4特殊类铸造工艺 8

2.2.5方案的确定 9

2.3造型与制芯方法的选择 10

2.4浇注位置的确定 10

2.5分型面方案选择定 11

2.6浇注系统的设计 11

2.6.1浇注系统类型的选择 11

2.6.2浇注系统的尺寸设计 12

第3章 铸造过程模拟仿真的数值基础及原理 16

3.1铸造模拟技术的数学基础 16

3.2充型过程模拟的数值基础 16

3.2.1 SIMPLE算法 16

3.2.2 SOLA-VOF算法 17

3.3凝固过程模拟的数值基础 18

第4章 砂型铸造汽车变速箱机油泵体模拟仿真 19

4.1. AnyCasting软件分析内容 19

4.2 AnyCasting模拟分析 20

4.2.1模拟方案设计 20

4.2.2模拟过程 20

4.3模拟结果分析 24

4.3.1充型速度的影响 24

4.3.2浇注温度的影响 25

第5章 总结与展望 28

参考文献 29

致谢 31