重循环油蒸汽发生器的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

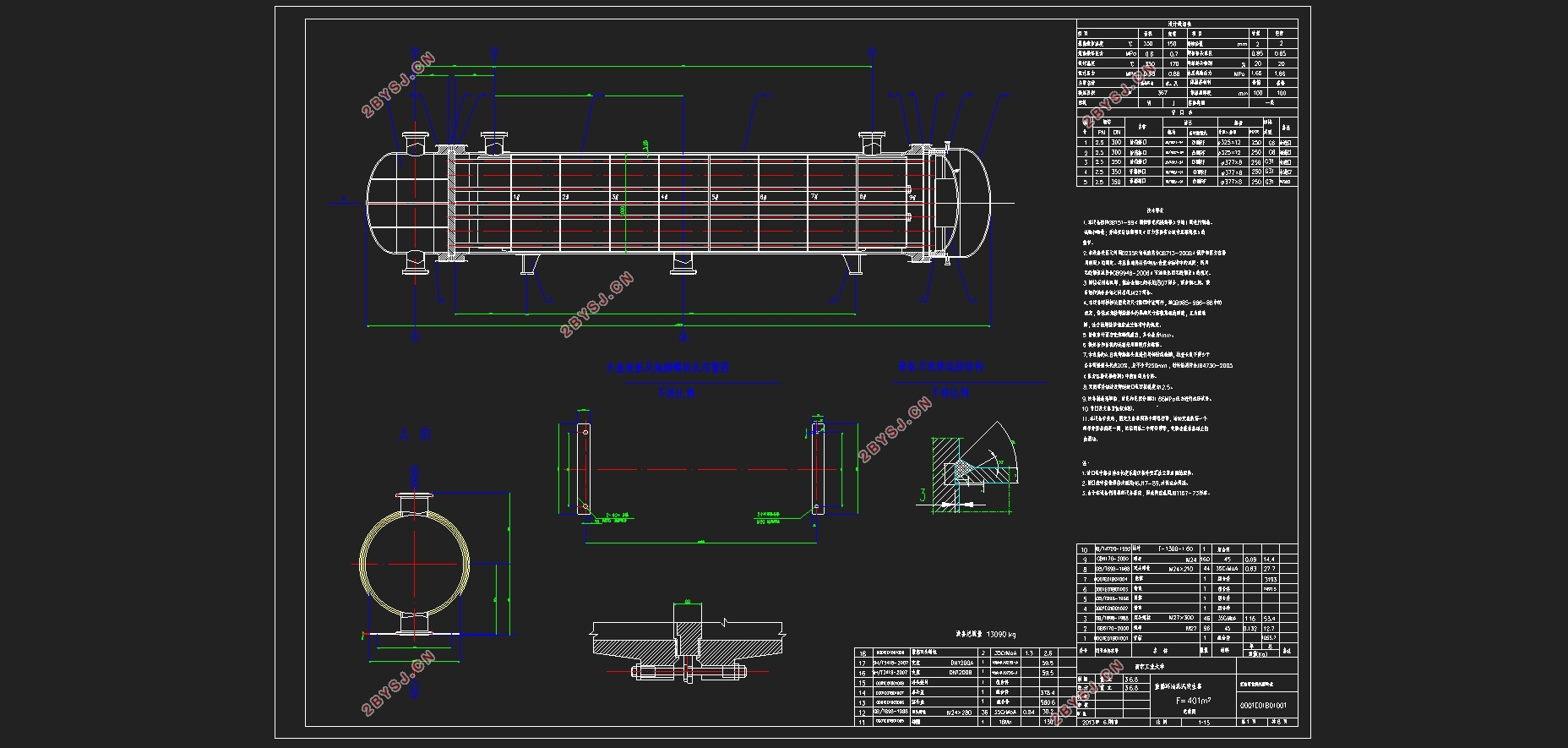

重循环油蒸汽发生器的设计(含CAD零件图装配图)(论文说明书7500字,CAD图6张)

摘 要

重循环油蒸汽发生器是在炼油工序过程中的一个主要设备,此设备为浮头式换热器。该设备利用重循环有将水加热成水汽。管程介质是重循环油,壳程介质是水。

本此设计的基础数据为工艺参数,首先对热工进行计算和对结构的选型和优化,从而能使得装置能满足工艺要求。最后,按照相应的规范对设计的部件等进行一定的强度校核,于此同时还采用了SW6-1998V3.1对此次设计进行了强度计算校核,并和前面的计算结果进行比较。本设备按GB151-1999《管壳式换热器》进行制造,试验和验收,并接受劳动部颁发《压力容器安全技术监察规程》的监督。

关键词:蒸汽 发生器 浮头式

The Design of Steam Generator for Re-circulating Oil

Abstract

The main equipment for the oil refining process is re-circulating oil steam generator. The main equipment of floating head heat exchanger The device will use re-circulating oil heat water to steam. The tube medium is re-circulating oil, and water as the shell medium.

Process parameters are the basis of the design, first the thermal calculation is done, then selection and optimization of structure are carried out, which can makes device can meet the technological requirements. Finally, according to the specification the strength check of the components have been done , at the same time the SW6-1998 v3. 1 also be used to calculate the strength and check the design, and the calculation results are compared. The equipment is produced ,tested and accepted by the GB151-1999. The equipment should be supervised by Regulation of security technique supervise of pressure vessel.

Keywords: steam; generator; floating head

目 录

摘要 I

ABSTRACT Ⅱ

第一章换热器分类及浮头式换热器 1

1.1 换热器简介 1

1.2 换热器分类 1

1.3浮头式换热器 2

1.3.1简介 2

1.3.2浮头式换热器特点 3

第二章 换热器工艺计算 4

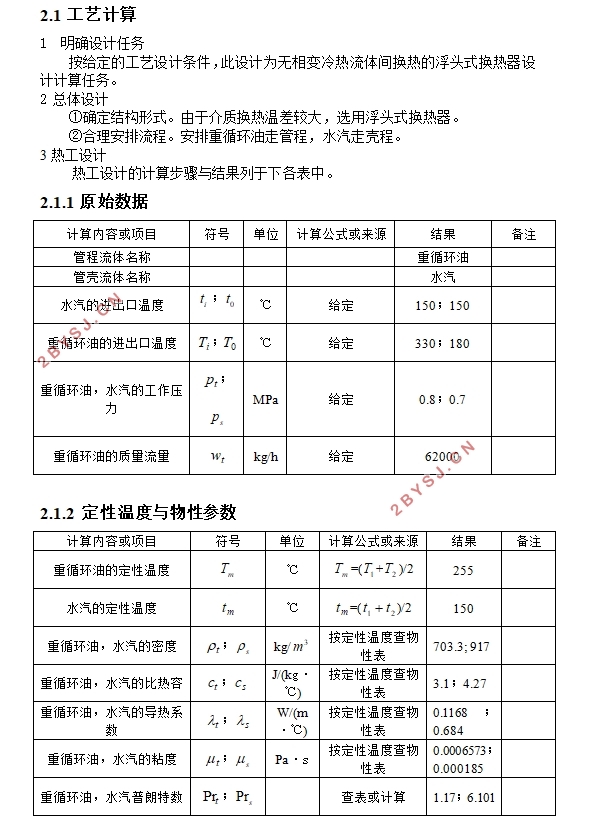

2.1 工艺计算 4

2.1.1原始数据 4

2.1.2定性温度与物性参数 4

2.1.3物料与热量衡算 5

2.1.4有效平均温差 5

2.1.5初算传热面积 5

2.1.6换热器结构设计 5

2.1.7管程传热与压降 6

2.1.8壳程传热与压降 7

2.1.9总传热系数 8

2.1.10传热面积与壁温核算 9

第三章 详细结构设计 10

3.1 详细结构设计 10

3.2 sw-6校核 14

第四章 结语 23

参考文献 24

致谢 26