轴瓦冲裁自动送料机构及模具设计

无需注册登录,支付后按照提示操作即可获取该资料.

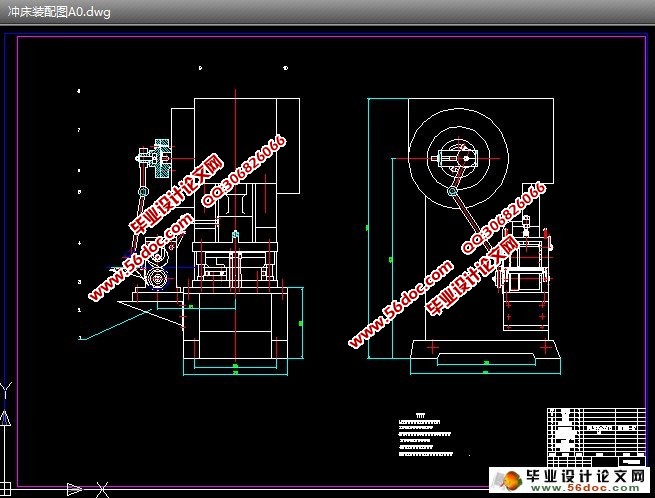

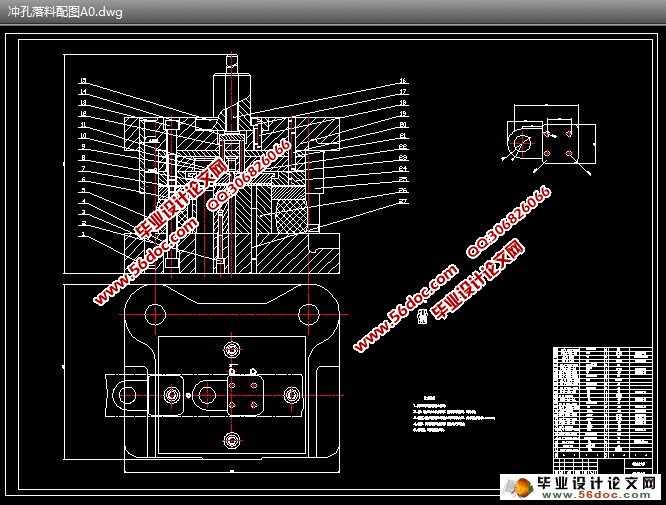

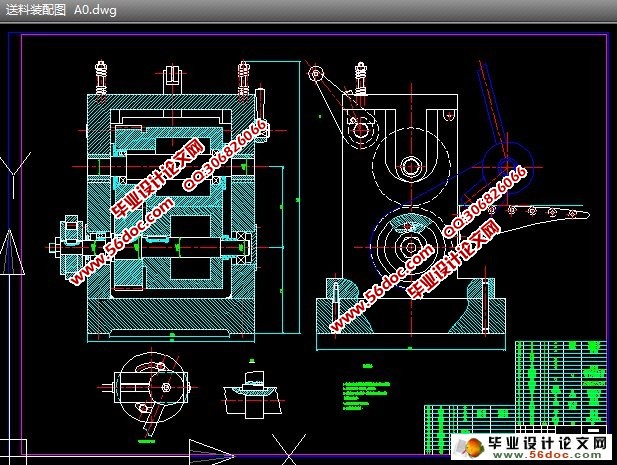

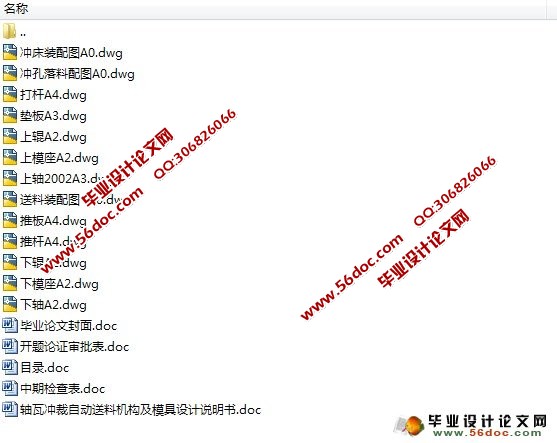

轴瓦冲裁自动送料机构及模具设计(选题审批表,任务书,开题报告,中期检查表,论文说明书15400字,CAD图13张)

摘 要:我的毕业设计是轴瓦冲裁自动送料机构及模具设计,主要涉及到冲孔落料复合模的设计。模具的生产主要是大批量的生产,而且模具可以保证冲压产品的尺寸精度和产品质量,模具的设计与制造主要考虑到模具的设计能否满足工件的工艺性设计,能否加工出合格的零件,以及后来的维修和存放是否合理等。在本次设计的轴瓦中,不仅要考虑要使做出的零件能满足工作要求,还要保证它的使用寿命。其次设计中还要考虑到它的实际工作环境和必须完成的设计任务,以及很多关于我所设计模具的知识,包括它的使用场合、选择合适的模具及送料方式等,从这里可以知道模具设计是一项很复杂的工作,所以设计要不断的改进直到符合要求。

关键词:轴瓦;模具;复合模

The Design of the Bush Punching Automatic Feeding Machine with the Mold

Abstract: My graduation design is the Bush punching Automatic feeding machine with the Mold. The main concern is the design of the composite modulus that contains the punching die and the blanking die. Because of large quantities production of the mold, either the mold can guarantee the high dimensional accuracy and its quality of product; the molds' design and manufacture must consider weather the mold can meet the requirements of the work piece craft. Also must consider weather the mold can process the qualified part. Of cause, it also must consider weather the mold's service and store is reasonable. In the design of the bush, I not only should consider the parts can meet the job requirements, but also must ensure that its service life. Second in this design its actual work environment and must complete design task should be consider. And a lot about the knowledge of the mould what I design. Including the use of occasion, choose right mould and its feed way. Here you can know that mold design is a very complicated work. So it should continue to improve until meets the requirement

Keywords: Bush; Mould; Composite die

本文主要研究内容

通过对轴瓦的结构进行工艺分析,结合已修“冲压工艺及模具设计”课程的知识,为其制订出一套冲压工艺方案,并设计其中一道工序的冲压模具及送料机构。

主要技术要求:

1)冲压工艺应基本合理,能完成零件加工并保证其技术要求;

2)模具及送料机构结构应合理,能完成本工序的冲压过程并保证本工序的技术要求。

2 工艺方案的选择

2.1 零件的工艺性分析

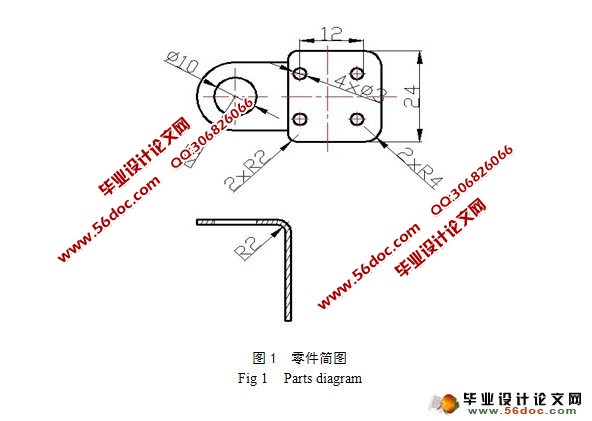

本设计是关于轴瓦冲裁自动送料机构及模具设计,材料是Q215号钢,板厚是1.3如图1所示

冲压工艺设计的基本要求为:

1)材料利用率要高,即原始材料消耗要尽可能少;

2)考虑工厂的具体生产条件,制定出的工艺方案要技术上方便可行,经济上合理;

3)工序组合方式和工序排列顺序要符合冲压变形规律,能保证冲制合格的工件;

4)工序数量尽可能少,生产效率尽可能高;

5)制定的工艺规程,要方便工厂、车间的生产组织与管理。

良好的冲压工艺能保证材料消耗少、工序次数少、模具结构简单、操作方便、产品质量稳定等。从某种意义上讲,冲压工艺的质量就决定了模具的质量,因此,制定出合理的冲压工艺方案是至关重要的。由零件图可以知到,零件的形状简单,便于实现少废料排样;在各直线或曲线的连接处,都采用了圆角过渡;零件的精度和断面粗糙度等都符合冲裁工艺的要求。零件尺寸公差没有特殊要求,按IT10取,利用普通的冲裁形式可以达到图样要求。由于该零件外形简单,形状规则,适于冲裁加工。

目 录

摘要.....................................................................1

关键词...................................................................1

1 前言.............................................................. ....2

1.1 背景........................................................ ....2

1.2 冷冲模成形特点..................................................2

1.3 发展趋势........................................................3

1.4 本文主要研究内容................................................3

2 工艺方案的选择........................................................4

2.1 零件的工艺性分析................................................4

2.2 模具的结构形式..................................................5

2.2.1 冲裁力和弯曲力的计算......................................5

2.2.2 卸料力、推件力和顶件力的计算..............................6

3 冲压模具设计..........................................................7

3.1 排样............................................................7

3.2 模具压力中心的确定..............................................8

3.3 压力机的选择....................................................9

3.4 模具主要零部件的设计...........................................10

3.4.1 冲孔凸模的结构设计.......................................10

3.4.2 凸凹模的结构设计.........................................11

3.5 冲压模具标准件的选择...........................................12

3.5.1 模架的选择...............................................12

3.5.2 挡料销...................................................15

3.5.3 卸料装置.................................................15

3.5.4 推件装置.................................................15

3.5.5 导向零件设计与标准.......................................16

3.5.6 模柄的选用...............................................16

3.5.7 凸模固定板与垫板.........................................17

3.5.8 冲压模具结构图...........................................18

4 自动送料机构设计.....................................................18

5 自动送料机构的设计...................................................20

5.1 辊轴送料机构的原理、机构及工作过程.............................20

5.2 结构特性.......................................................21

5.2.1 辊子.....................................................21

5.2.2 压紧装置.................................................23

5.2.3 抬辊装置.................................................24

6 驱动机构.............................................................24

6.1 送料进距调节装置分析...........................................25

6.2 送料精度的分析.................................................26

6.3 间歇运动机构...................................................26

6.4 齿轮的设计及校核...............................................26

6.5 轴的设计及校核.................................................32

6.6 轴承的设计和校核.......................... ....................36

6.7 键的设计和校核.............................. ..................36

7 润滑与密封.................................. ........................38

7.1 润滑...........................................................39

7.2 密封...........................................................39

8 结论.................................................................39

参考文献................................................................39

致谢....................................................................40

附录....................................................................40

附录

附录1:A0图纸2张

附录2:A1图纸1张

附录3:A2图纸3张

附录4:A3图纸3张

附录5:A4图纸4张