罩形件弯曲模设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

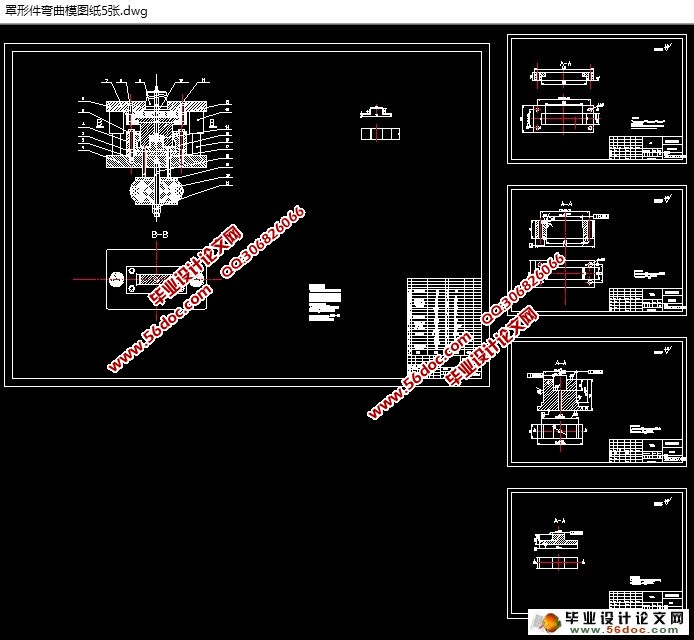

罩形件弯曲模设计(含CAD零件图装配图)(开题报告,文献综述,设计说明书9800字,CAD图5张,实习报告)

摘 要

由于采用模具进行生产产品能提高生产的效率、降低生产的成本、节约原材料,并且在一定的尺寸精度范围内能够保证产品零件的互换性等因素,模具在我国各个行业都得到了广泛的应用。在机械、电子、轻工、国防等行业的生产中起到了重要的作用。

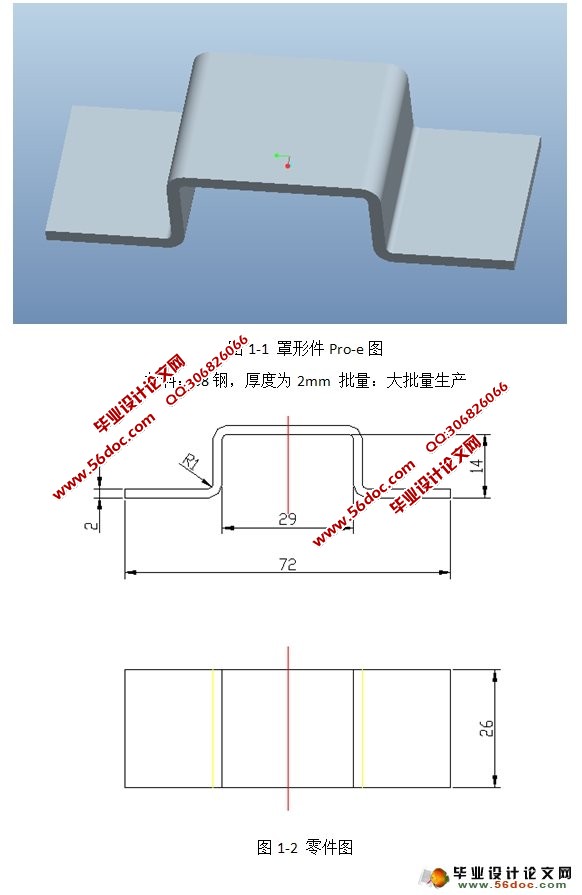

本文设计的罩形件弯曲模采用的是冷冲压成型的过程,分析零件的结构尺寸、生产的批量、零件的质量和要求。简要分析了零件的胚料形状和尺寸、排样的方法,冲压工序的安排和顺序。并具体分析了模具的主要工作零件,如凸凹模、弯曲凸模、卸料装置、凸模固定板等。通过查阅资料计算了凸凹模等零部件的重要数据,编订了重要零部件的加工工艺卡片,绘制工作零部件的零件图和装配图。冲压成形技术早已经成为国内外比较成熟的一种金属成型加工工序,各种板料零件都是用该方法加工的。其的优点有:高效率、 轻重量、 精度好、成本低,而且还有自动化和机械化等优点。本文提供的设计理念并不是最优选择,只是课题要求的一种方案,不建议在工业生产中使用该方案。

模具行业的发展迅速,导致了这个行业的迅速扩张,实用性技术人才急需,使全国大学生的就业率提高了许多,促进了国内的生产水平。专家认为该行业将会继续向前发展,推动社会的平均水平,使未来生活更加方便快捷,更加美好。

关键词:模具设计,罩形件,弯曲,复合模

ABSTRACT

To finish and accuracy by using mold production products can improve production efficiency, reduce production cost, saving raw materials, and in a certain size range to ensure product parts interchangeability and other factors, the mold in our country in various industries have been widely used in machinery, electronics, light industry, national defense industry production plays an important role. In this paper, the design of the hood shape bending die with cold stamping forming process, the analysis of parts structure size, production batch, parts quality requirements in three different stamping process (single process, complex processes and continuous processes) are determined by a pair of compound die parts The bending process. A brief analysis of the parts of the blank shape and size, layout method, stamping process arrangement and sequence. And a detailed analysis of the mold of the main working parts, such as punch and die, the bending punch, remove the feeding device, the parts drawing and assembly drawing of the punch fixed plate. Stamping technology has already become the domestic and foreign mature a metal forming process, a variety of sheet metal parts are processed by the method. Has its advantages: high efficiency, light weight, good precision, low cost and automation and mechanization advantagesThrough access to information to calculate the die of convex and concave parts of important data, compiled in the important parts of the machining process card, drawing parts. This paper provides the design concept is not the optimal choice, just a project subject to the requirements of the is not recommended in industrial production.

Mold industry is developing rapidly, resulting in the rapid expansion of the industry, practical and technical personnel needed, the college students employment rate improved a lot, and promote the level of domestic production. Experts believe that the industry will continue to move forward and promote social average level, the future life more convenient, more beautiful.

Key words: mold design, cover, bending, compound die

目 录

绪论....1

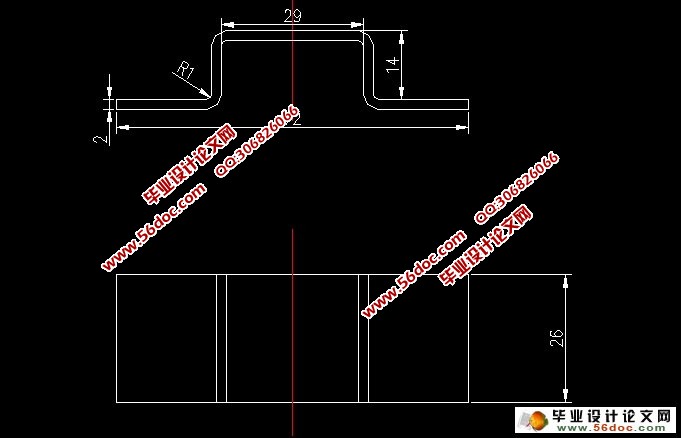

1.罩形件Pro-e图和零件图 2

1.1 罩形件pro-e图 2

1.2 零件图 3

2. 罩形零件的工艺分析 4

2.1 材料的选择及适用性 4

2.2.1 零件的结构分析 4

2.2.2 弯曲件弯曲半径的要求 4

2.2.3 弯曲件直边高度的多少对弯曲件成型的影响 5

2.3 弯曲件的精度选择 5

3 罩形件冲压工艺设计方案的选择 6

3.1 设计方案 6

3.2 设计方案分析 6

4 罩形件冲压工艺的设计及计算 7

4.1 毛坯展开尺寸的计算 7

4.1.1 中性层位置的确定 7

4.1.2 弯曲件的胚料尺寸计算 7

4.2 冲压工艺力的计算 8

4.2.1 冲裁力的计算 8

4.2.2 弯曲力的计算 8

4.3 压力机公称压力的确定 9

4.4 回弹值的确定 9

4.5 减小回弹的措施 10

4.6 排样和材料的利用率 10

5 罩形件弯曲模具工作零部件结构参数的计算 12

5.1 弯曲模结构的参数 12

5.1.1 弯曲模的结构确定 12

5.1.2 弯曲凸凹模的圆角半径的确定 13

5.1.3 凹模的工作部分深度 13

5.1.4 弯曲凸模、凹模之间的间隙 13

5.1.5 凸模和凹模工作部分的尺寸及公差 14

6 冲压复合模主要零部件的结构设计 16

6.1 主要零件的设计 16

6.1.1 凸模的设计 16

6.1.2 凹模和凸凹模的设计 16

6.1.3 凸凹模固定板 18

6.2 导料板的设计 18

6.3 推件装置的设计 19

6.4 标准模架和导向零件 19

6.5 弹性元件 20

7 压力机的校核 21

8 冲压工艺过程卡的编写 22

10 总装配图 24

设计总结 25

致 谢 27

主要参考文献 28