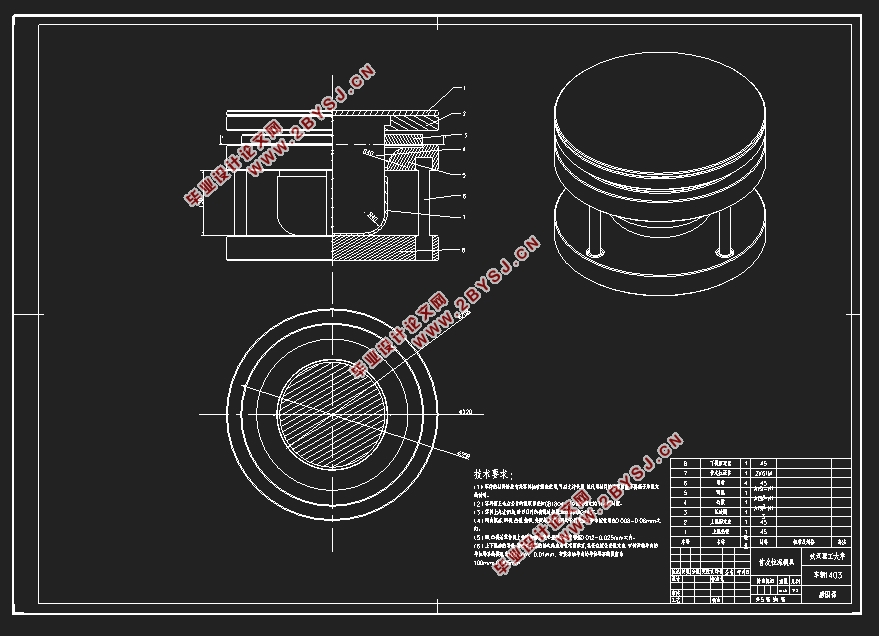

某筒形件拉深模具的三维设计及有限元分析(含CAD装配图,CATIA三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

某筒形件拉深模具的三维设计及有限元分析(含CAD装配图,CATIA三维图)(任务书,开题报告,论文说明书15500字,CAD图5张,CATIA三维图)

摘要

拉深成形技术的生产效率及材料利用率都比较高。用拉深成形生产的零件强度和刚度较好,精度较高。此外,拉深技术的应用范围也十分广泛,适合加工多种尺寸的零件。在工业部门占据重要地位,是工业发展的基础。随着计算机技术的发展和普及,CAD/CAE计算机辅助设计和分析技术也逐渐应用到工业生产制造的各个领域。其中拉深工艺过程的数值模拟技术日益成熟,影响了拉深技术轻量化和数值化的发展进程。拉深过程数值模拟仿真技术能够对板料的塑性变形过程进行模拟,预测出起皱、拉裂、变形不均匀等产品缺陷的位置,由此可以对相关工艺过程进行优化,提高产品质量,降低企业的生产成本。

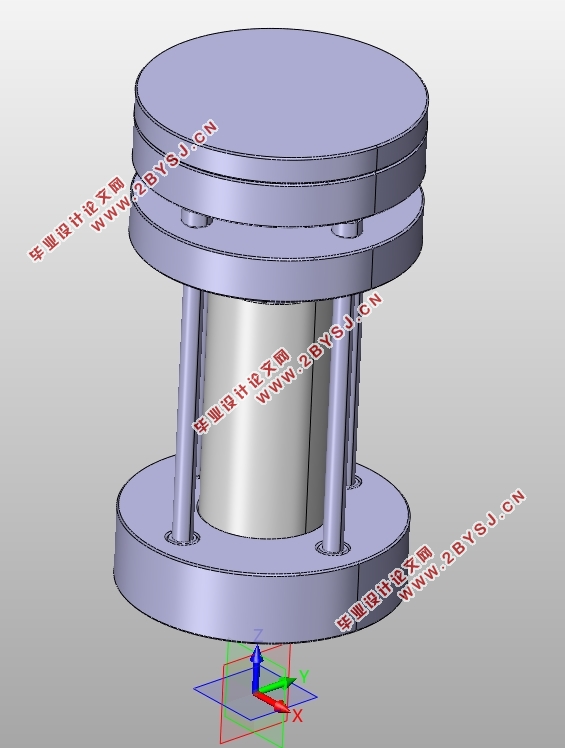

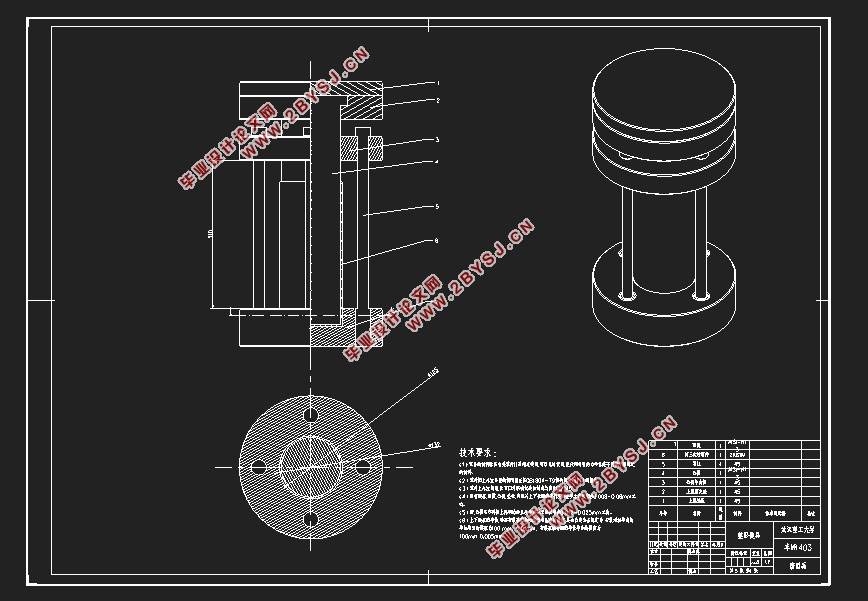

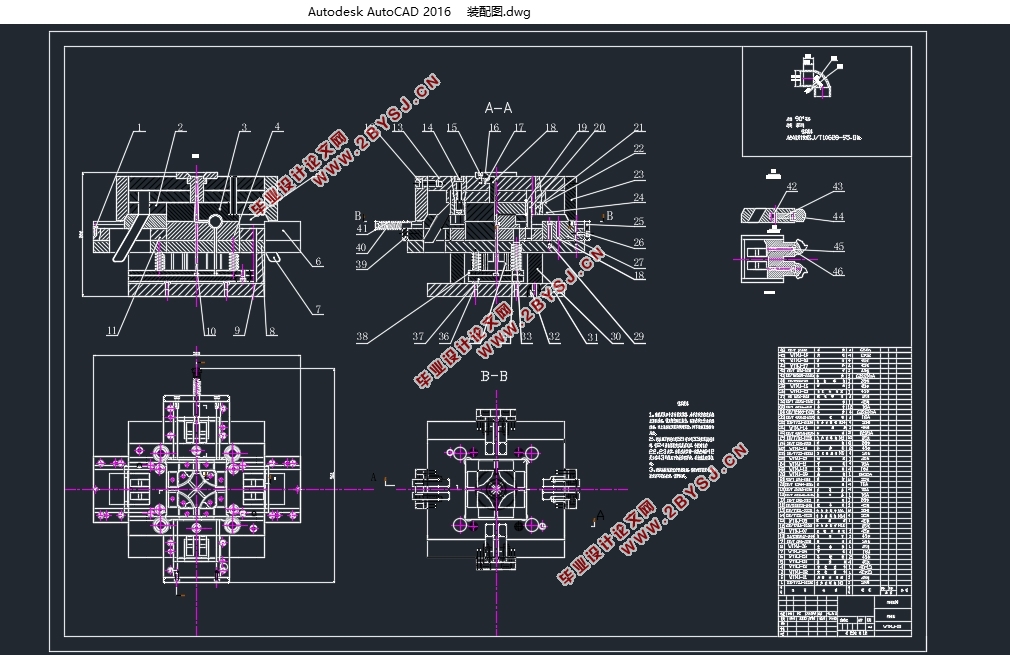

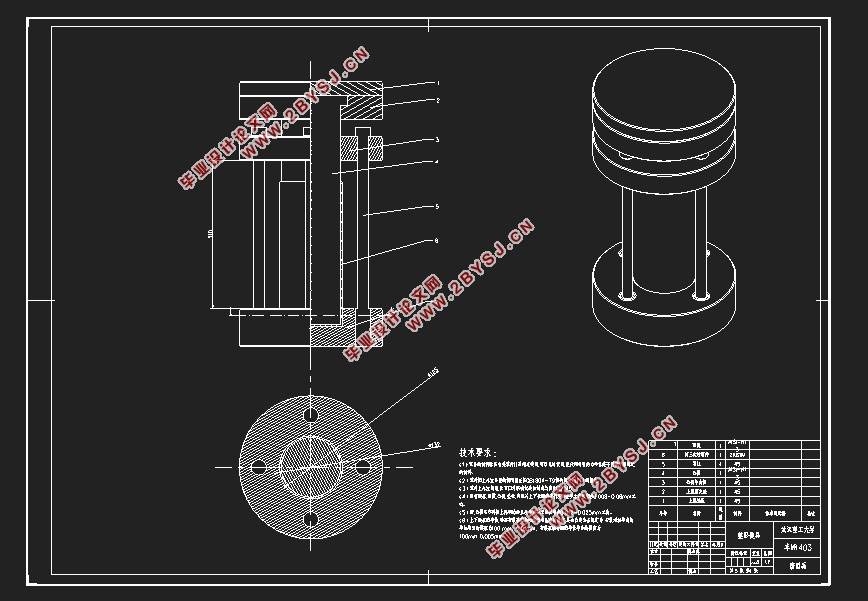

本文依据ZK61M镁合金某筒形件的零件图按拉深工序设计了相应的拉深模具。首先通过分析合金材料性能并对比各种拉深方式的特点,选择了对镁合金筒形件来说最为合适的拉深工艺,确定了模具类型和坯料形状尺寸;然后通过计算设计了首次拉深、二次拉深、三次拉深及整形工序的凸模、凹模,并使用CATIA三维制图软件进行三维建模;然后借助金属成形CAE软件DEFORM对该拉深工艺过程进行模拟仿真,分析得出ZK61M镁合金筒形件最佳拉深温度为420℃,最佳拉深速度为50mm/s,并对各拉深工序的模具结构进行了优化改进。论文工作为筒形件拉深工艺及模具的设计提供了指导参考作用。

关键词:拉深工艺,ZK61M镁合金,模具设计,有限元分析

Abstract

Deep drawing forming technology has high production efficiency and material utilization. The parts produced by deep drawing have better strength and rigidity and higher precision. In addition, deep-drawing technology has a wide range of machining possibilities and is suitable for machining a wide range of sizes. Taking an important position in the industrial sector is the basis for industrial development. With the development and popularization of computer technology, CAD/CAE computer-aided design and analysis technology is gradually applied to various fields of industrial production and manufacturing. Among them, the numerical simulation technology for the deep drawing process has become more and more mature, which has affected the development process of lightening and digitization of deep drawing technology. The numerical simulation technology of drawing process can simulate the plastic deformation process of sheet metal and predict the position of product defects such as wrinkling, cracking and non-uniform deformation, which can optimize the relevant process and improve product quality. The company's production costs.

This article according to the ZK61M magnesium alloy part of a cylindrical part drawing according to the drawing process designed a corresponding drawing die. Firstly, by analyzing the properties of alloy materials and comparing the characteristics of various drawing methods, the most suitable drawing process for magnesium alloy cylindrical parts was selected to determine the mold type and blank shape size; then the first drawing was designed by calculation. The three-dimensional modeling is performed using CATIA 3D graphics software; then the drawing process is simulated and analyzed by means of the metal forming CAE software DEFORM. The best drawing temperature of ZK61M magnesium alloy cylinder is 420°C, the best drawing speed is 50mm/s, and the mold structure of each drawing process is optimized and improved. The work of the thesis provides guidance for the drawing process of the cylindrical parts and the design of the die.

Keywords:Deep drawing process, ZK61M magnesium alloy, Mold design, Finite element analysis

零件工艺性分析

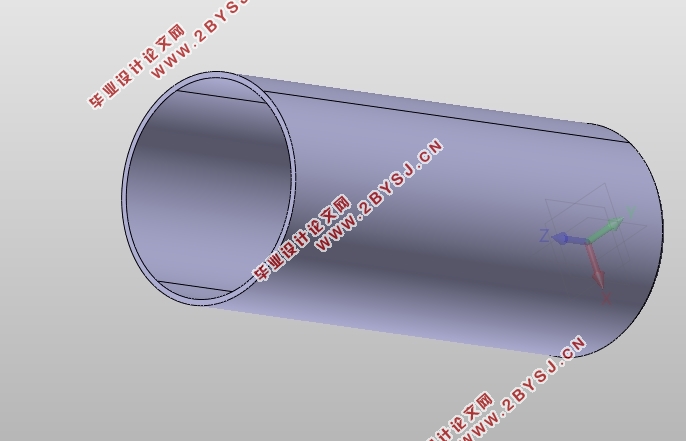

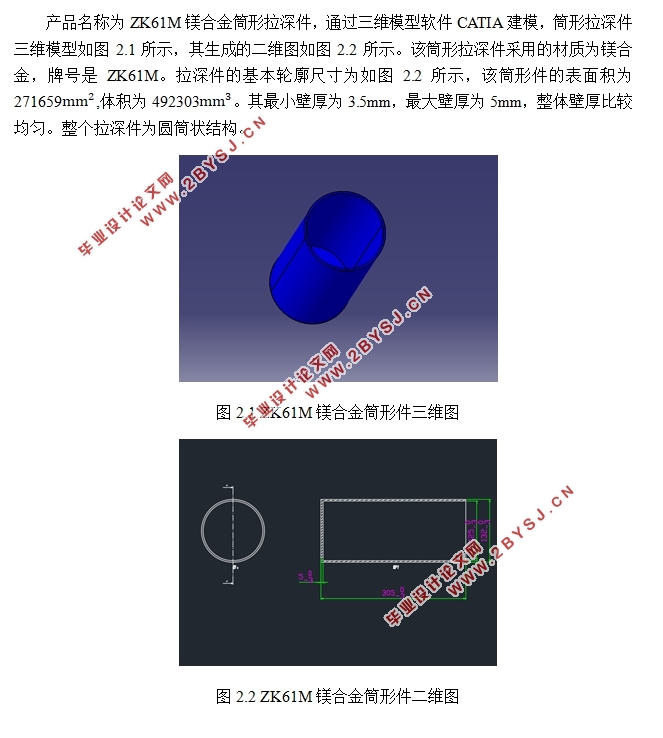

产品名称为ZK61M镁合金筒形拉深件,通过三维模型软件CATIA建模,筒形拉深件三维模型如图2.1所示,其生成的二维图如图2.2所示。该筒形拉深件采用的材质为镁合金,牌号是ZK61M。拉深件的基本轮廓尺寸为如图2.2所示,该筒形件的表面积为271659 ,体积为492303 。其最小壁厚为3.5mm,最大壁厚为5mm,整体壁厚比较均匀。整个拉深件为圆筒状结构。

目录

摘要 2

第1章绪论 6

1.1课题研究的背景及意义 6

1.1.1镁合金及其应用 6

1.1.2拉深成形技术 6

1.1.3数值模拟技术的作用 6

1.2国内外研究现状 7

1.2.1拉深成形的发展现状及趋势 7

1.2.2 拉深模拟仿真技术的发展现状与趋势 8

1.3课题研究内容与目标 9

第2章筒形件拉深工艺设计 10

2.1零件工艺性分析 10

2.2拉深成形方案选择 11

2.2.1拉深加工方式 11

2.2.2拉深加工类型 11

2.2.3拉深工艺方案的确定 13

2.3毛坯及其尺寸的确定 13

2.3.1确定切边余量 14

2.3.2计算毛坯直径 14

2.3.3计算每次拉深工序件的直径 15

2.3.4计算每次拉深工序件的高度 15

2.4凸模和凹模工作部分的尺寸及公差 16

2.4.1计算凸模和凹模工作部分的直径 17

2.4.2计算凸、凹模工作部分的圆角半径 18

2.4.3拉深模间隙的确定 20

2.4.4压边装置与压边力的确定 21

2.4.5拉深力的确定 22

第3章拉深过程有限元分析的数值基础及原理 22

3.1拉深模拟技术的数学基础 22

3.2拉深过程模拟的数值基础 23

3.2.1动力显式算法 23

3.2.2静力隐式算法 23

第4章ZK61M镁合金筒形件拉深模拟仿真 24

4.1 DEFORM软件分析内容 24

4.2 DEFORM模拟分析 24

4.2.1模拟方案分析 24

4.2.2模拟过程 24

4.3模拟结果分析 29

4.3.1拉深速度的影响 30

4.3.2拉深温度的影响 32

第5章总结与展望 35

参考文献 36

致谢 37