38+60+38m预应力混凝土变截面连续梁桥施工图设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

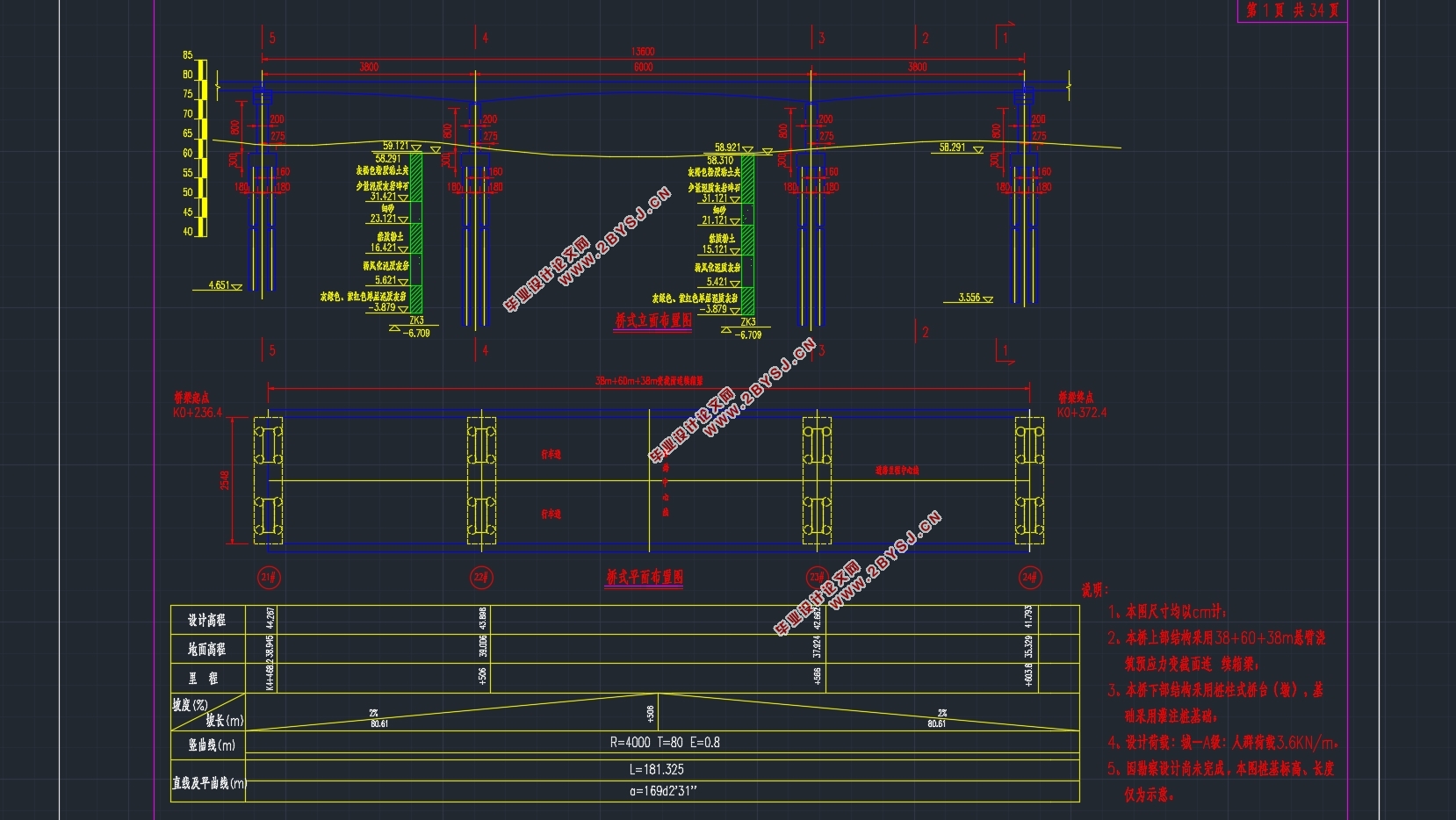

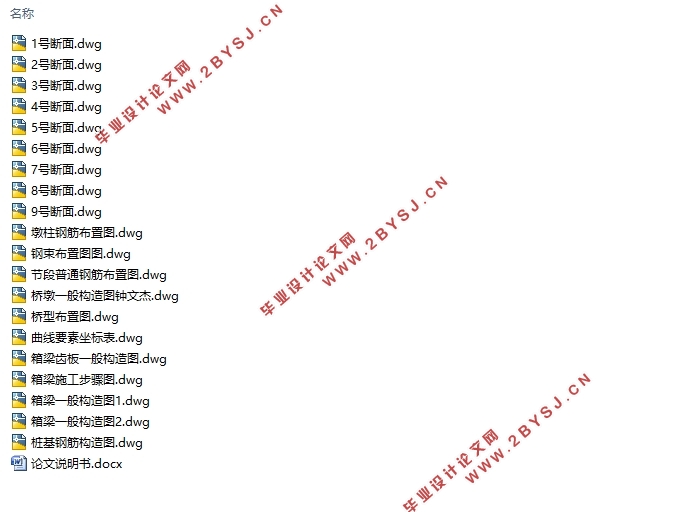

38+60+38m预应力混凝土变截面连续梁桥施工图设计(含CAD图)(论文说明书21000字,CAD图20张)

摘要

本毕业设计题目为38+60+38m预应力混凝土变截面连续梁桥施工图设计。大跨径桥梁的设计计算当中,跨中的弯矩会非常大,而连续的梁桥中,支点截面的负弯矩可以对其进行抵消卸荷。因此,采用预应力混凝土变截面连续梁,可以有效缩短桥梁施工所需的时间,降低了材料费投入,流程更简单,施工操作更方便,也更容易保证质量。

在进行桥梁的设计工作之前,需要对桥梁工程、基础工程以及结构力学原理等科目进行一个综合的回顾。做到能对所需设计的桥型的各个方面比如受力等的一个充分的了解。这样在进行桥梁设计时能更加的轻松方便。并且还需要熟悉Midas软件的应用,这有利的模型结构的正确建立。

进行设计的第一步便是熟悉桥址的地形地貌以及地质情况。然后开始进行桥型的比选。本设计从受力及优缺点上对几个桥梁结构进行了比较,最终选定连续刚构桥为本设计的桥型。然后便是初步拟定桥梁的几何尺寸,这里需要多参考有关资料作出合适的选择。

然后,本设计通过Midas软件,利用所拟定的尺寸,便可以建立出一次成桥的模型。施加恒载经过计算得到内力结果,对预应力束进行了估计。接着便可导入钢束及移动荷载施工阶段等,进行各阶段的内力验算如正截面主压应力验算等。

除此之外,本设计还考虑了预应力损失及次内力可能会对结构所产生的影响并对结果进行分析,并添加车辆荷载及收缩徐变等确保桥梁设计的安全。最后,本设计对桥梁结构的行车道板、下部结构的设计进行了手算。 经过反复研究计算,本次设计可以较为客观公正的计算出桥梁的受力状态,并提供了许多关键的信息来指导工程施工。

关键词:Midas;连续梁桥;桥梁结构;内力验算

Abstract

The undergraduate design of 38+60+38m Prestressed Concrete Continuous Girder Bridge with Variable Cross Section. Because the long-span bridge in the external load and under the action of the fulcrum section will appear a larger negative moment. From the absolute value of the prestressed anchor, the negative moment of the fulcrum section is greater than the positive moment of the cross section. Therefore, the use of prestressed concrete variable cross-section continuous beam, can shorten the overall duration, reduce material costs, the process is more simple, easier to operate and easier to ensure quality.

Before the bridge design work, the need for bridge engineering, basic engineering and structural mechanics and other subjects to conduct a comprehensive review. So as to be able to design the bridge of the various aspects of the force. So when we design the bridge that can be more relaxed and convenient. And we also need to be familiar with the Midas software application, which is conducive to the correct establishment of the model structure.

The first step in the design is familiar with the topography of the bridge site and geological conditions. And then we can start to choose the bridge type of comparison. The design of the bridge from the force and the advantages and disadvantages of several bridge structures were compared. The continuous rigid bridge is the final selection of for the design of the bridge. And then we should decide the initial development of the bridge geometry, where need for more reference to the information to make the appropriate choice.

Then, we can start Midas software by using the proposed size.We can build a bridge model. The results from the model is estimated to calculate the number of .prestressed beam. And then the steel beam and mobile load construction stage can be imported in the model.Now we can start the various stages of the internal force calculation, such as the main section of the main compressive stress calculation.

In addition, the design also takes the impact of prestress loss and secondary forces on the structure into account and get the results of the analysis. The design add vehicle load and shrinkage into the model and so on to ensure the safety of bridge design. Finally, the design of the bridge deck and the lower structure is done by hand.

According to the Midas calculation results and through manual checking.The results of the analysis shows that the graduation design method is correct.The construction phase and the use of section of the internal force and stress are in line with the requirements and the design task is completed. After repeated study and calculation, this design can be more objective and fair to calculate the stress state of the bridge, and provides a lot of key information to guide the construction.

Key words: Midas; continuous rigid frame bridge; bridge structure; internal force checking

目 录

摘要 I

Abstract II

第1章绪论 1

1.1确定桥梁方案 1

1.2连续梁桥 1

1.3毕业设计的价值 2

第2章桥梁总体布置及结构主要尺寸 3

2.1桥跨布置 3

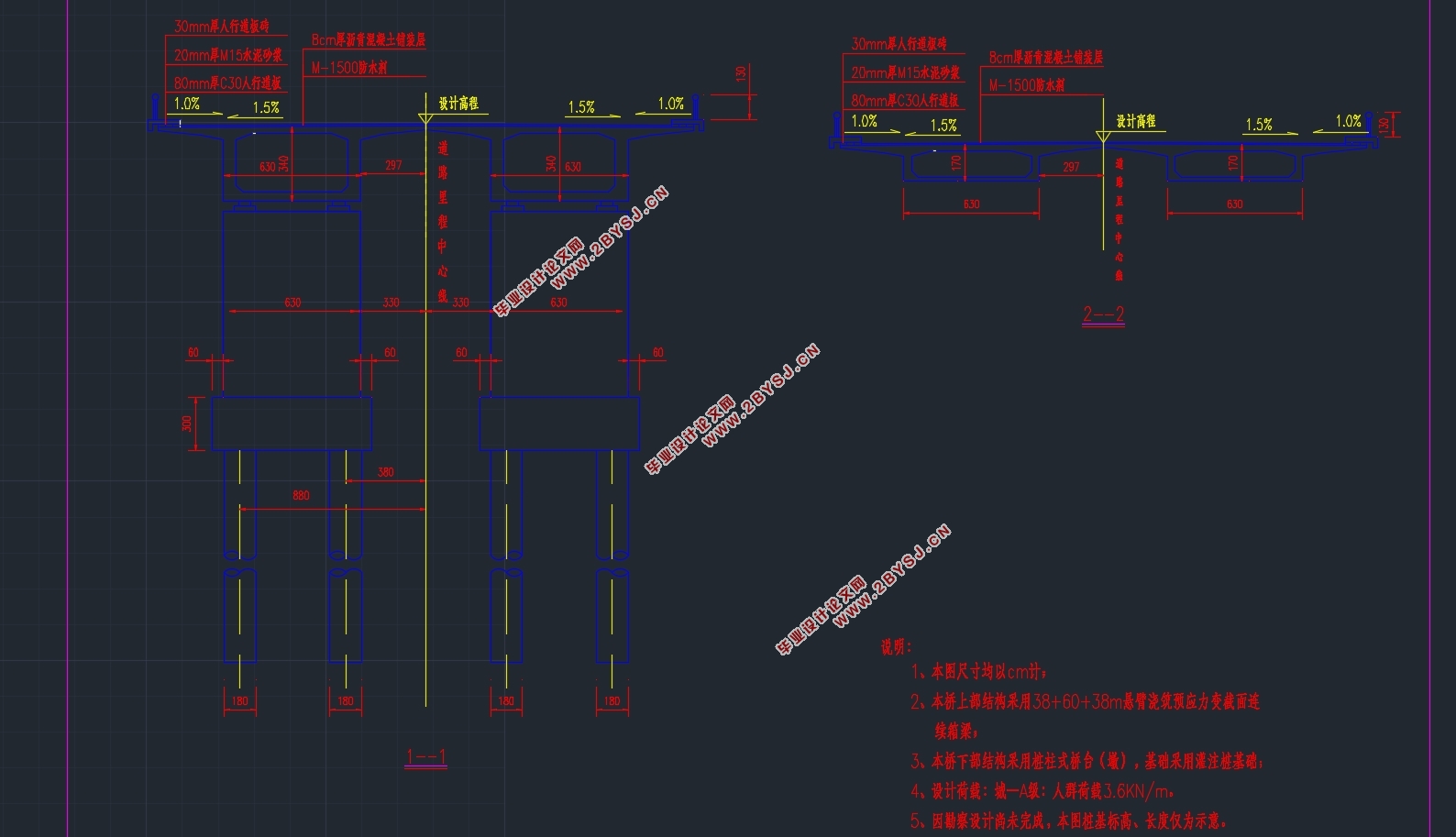

2.2上部结构尺寸拟定 4

2.2.1 跨度 4

2.2.2 主梁高度 4

2.2.3 箱梁腹板厚度 4

2.2.4 箱梁底板厚度 5

2.2.5 梁段的划分 5

2.2.6 箱梁顶板厚度 5

2.3下部结构尺寸拟定 7

2.3.1墩身尺寸 7

2.3.2桩基础尺寸 7

2.3.3承台尺寸 9

2.4设计依据及基本资料 10

第3章建模 12

3.1模型简化 12

3.2 3.2 模型的建立 12

3.2.1 节段的划分 12

3.2.2 材料参数 13

3.2.3 荷载参数 14

3.2.4 截面的定义以及边界条件的添加 14

3.2.5 施工阶段的定义 14

第4章桥梁结构内力计算 16

4.1恒载内力 16

4.2活载内力 19

第5章预应力钢筋设计及预应力损失计算 22

5.1 纵向预应力筋估算 22

5.1.1 5.1.1 手算原理及方法 22

5.1.2 5.1.2 Midas电算原理 25

5.1.3 5.1.3 手算电算结果及对比 26

5.1.4预应力筋的布置 27

5.2 预应力损失及有效预应力计算 28

5.2.1 预应力筋与管道之间的摩擦引起的预应力损失 28

5.2.2锚具变形、钢筋回缩和接缝压缩引起的应力损失 29

5.2.3 预应力钢筋与台座之间的温差引起的损失 29

5.2.4 弹性压缩损失 30

5.2.5 钢筋松驰引起的应力损失 30

5.2.6 混凝土收缩和徐变引起的预应力损失 31

5.2.7 预应力损失计算结果 31

第6章次内力计算及内力组合 37

6.1温度次内力 37

6.1.1计算依据及方法 37

6.1.2温度次内力计算结果 38

6.2基础不均匀沉降次内力 42

6.3预应力次内力 44

6.4收缩次内力 46

6.5徐变次内力 48

6.6内力组合 50

6.6.1承载能力极限状态组合 50

6.6.2正常使用极限状态组合 52

第7章主要截面验算 55

7.1承载能力极限状态截面验算 55

7.1.1 计算依据 55

7.1.1计算结果 56

7.1.1使用阶段斜截面抗裂验算 58

7.1.2斜截面抗剪验算 61

7.2正常使用极限状态截面验算 62

7.2.1使用阶段正截面抗裂验算 62

7.2.2挠度验算 65

7.3持久状况和短暂状况构件的应力验算 65

7.3.1使用阶段正截面压应力验算 65

7.3.2使用阶段斜截面主压应力验算 67

7.3.3施工阶段正截面法向应力验算 70

7.3.4受拉区钢筋的拉应力验算 73

第8章行车道板计算 76

8.1中间单向板计算 76

8.1.1恒载内力 76

8.1.2活载内力 76

8.1.3内力组合 77

8.2外边梁悬臂板内力计算 78

8.2.1恒载内力 78

8.2.2活载内力 78

8.2.3内力组合 79

8.3配筋设计 79

8.3.1支点处配筋 80

8.3.2跨中配筋 80

第9章下部结构计算 82

9.1桥墩计算 82

9.1.1内力计算 82

9.1.2截面设计 82

9.1.3截面设计 83

9.2钻孔灌注桩计算 84

9.2.1基本假定 84

9.2.2桩径桩长的拟定 84

9.2.3桩基础内力计算 84

9.2.4桩基础内力验算 90

9.2.5桩身配筋计算 90

参考文献 93

致谢 94