液压惯性元件的流态分析(含CAD图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

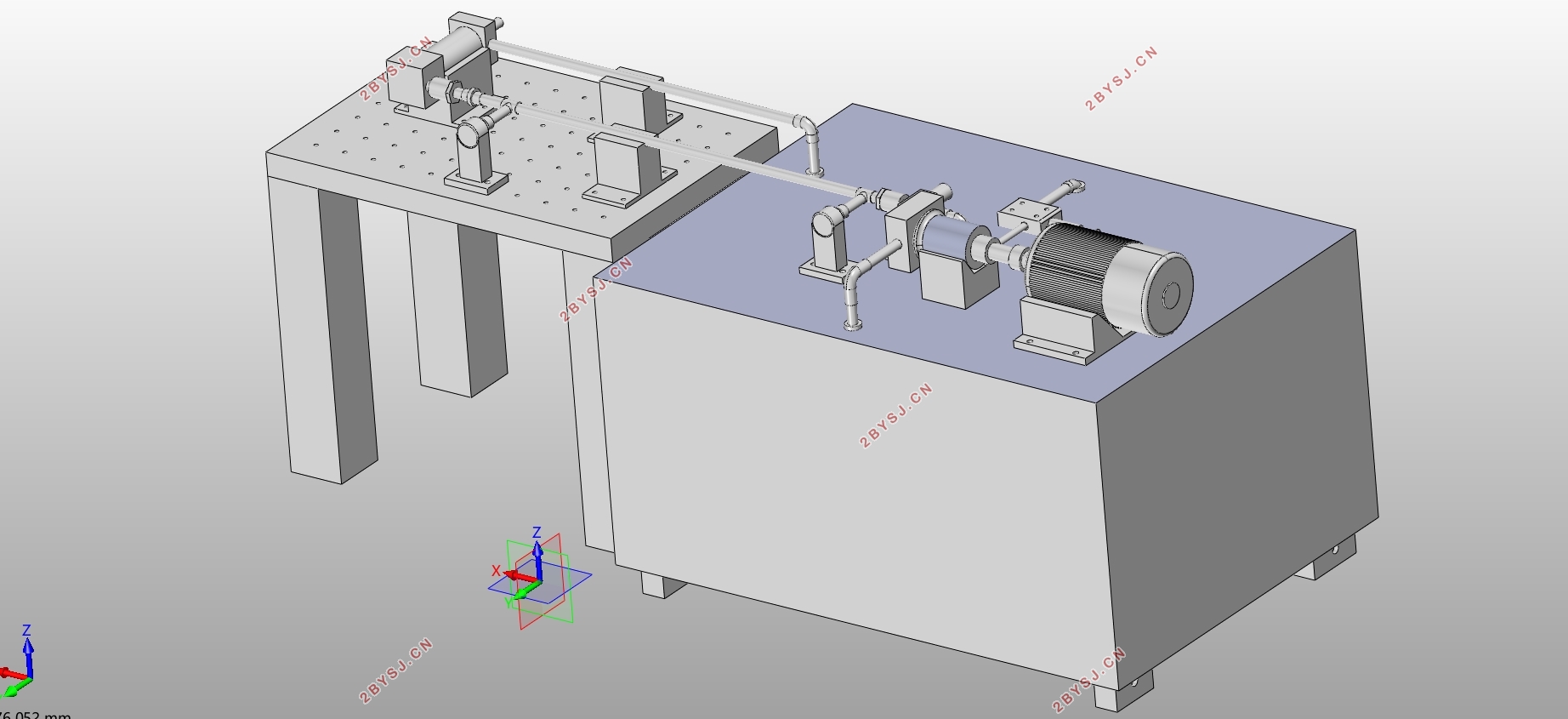

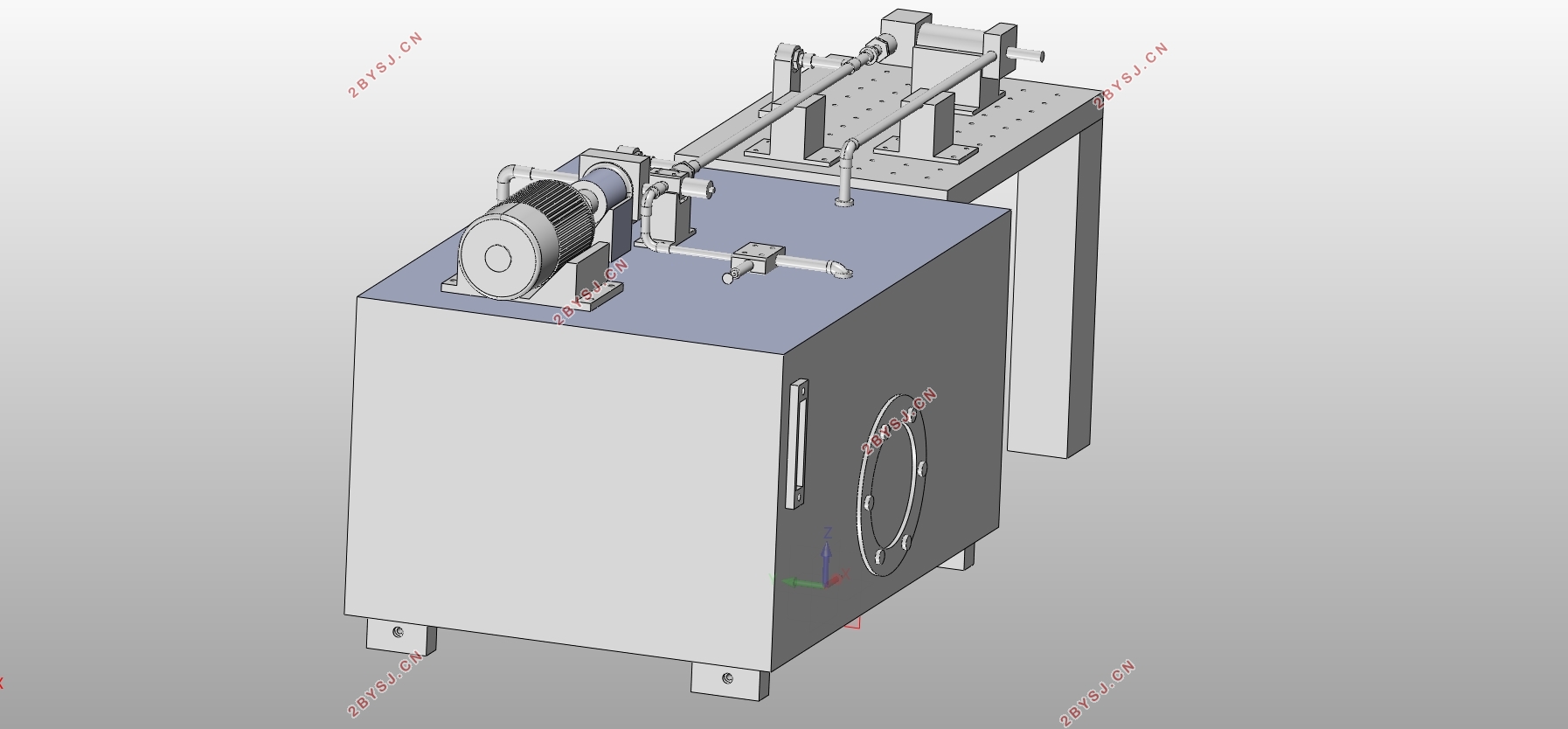

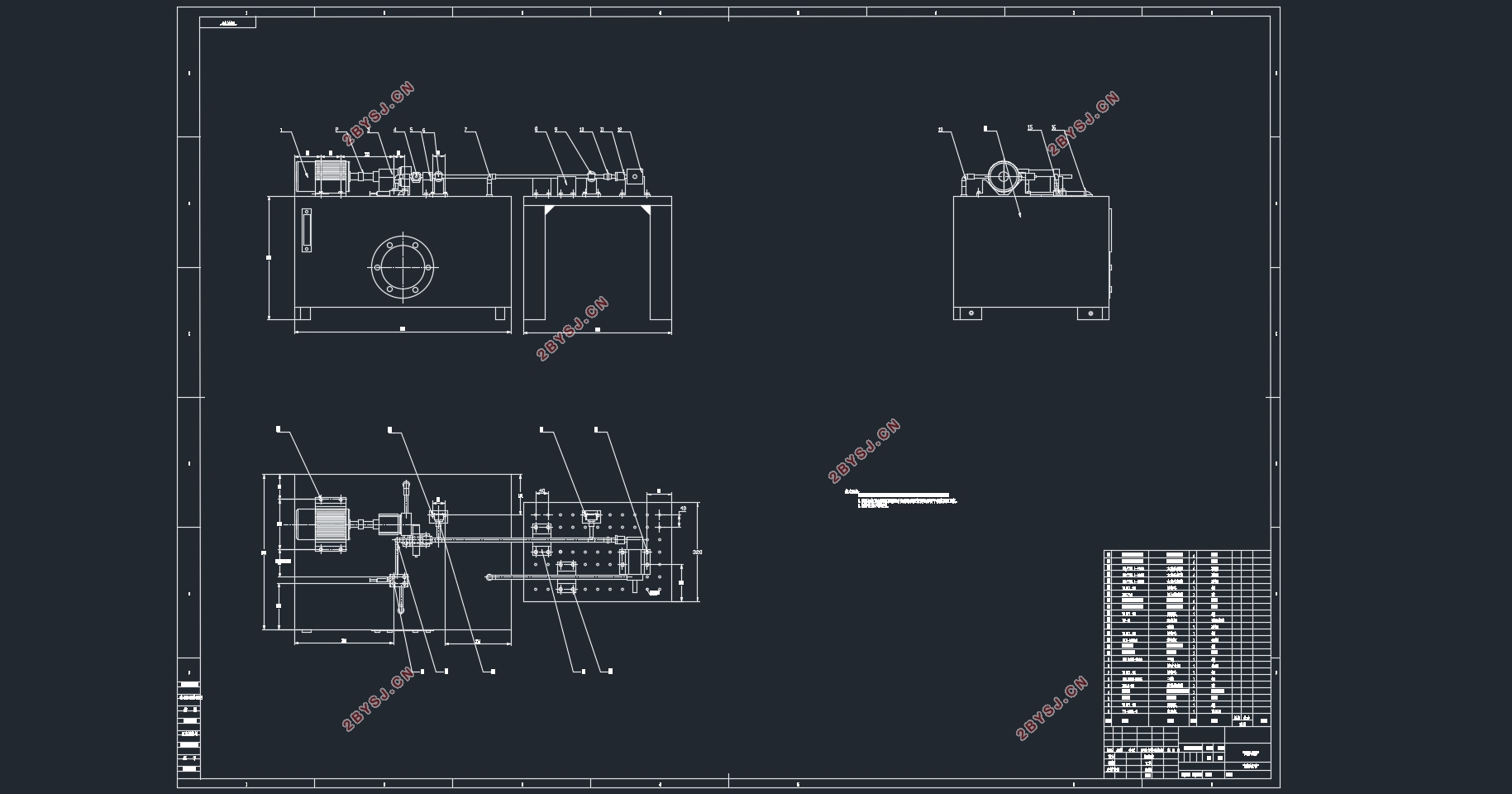

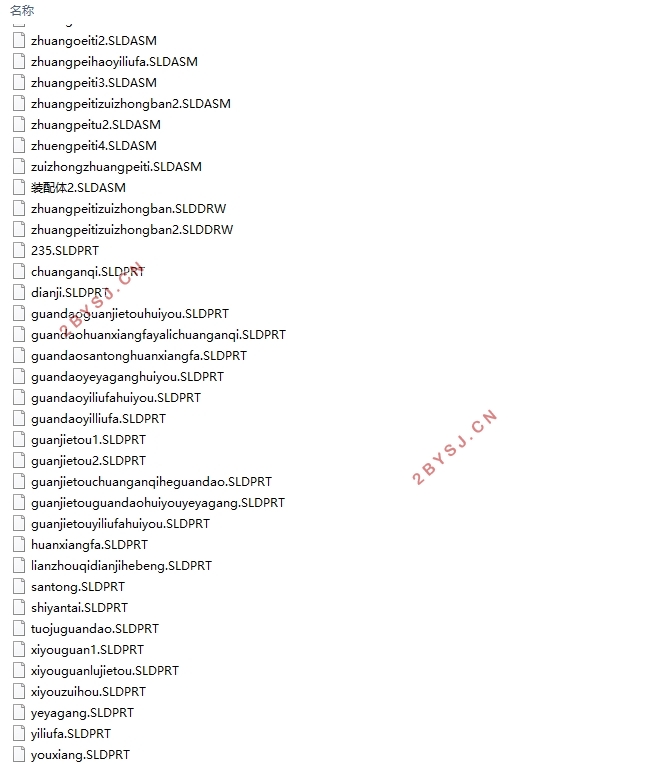

液压惯性元件的流态分析(含CAD图,SolidWorks三维图)(任务书,开题报告,论文说明书12200字,CAD图纸1张,SolidWorks三维图)

摘 要

液压传动相比与其他传动具有体积小、可方便地实现无极调速、易实现过载保护和操作简单等优点,因此在当今工业化中应用广泛。但是由于液压系统的自身特点,其存在的液压冲击是不可避免的。与电气系统类似,液压系统中也存在着惯性元件,即液感和液容,它们和电容电感一样,有感性和容性的性质。由于其物理本质,液感和液容可以有效地抵抗液压系统中产生的液压冲击,而液感和液容又与管道的参数密切相关。基于以上理念,本文主要研究针对某一特定的液压系统,如何设置合理的管道参数才能够有效地抵抗因阀的快速启闭而引起的液压冲击。本文先采用数学计算的方法,推导出液压冲击和液容液感的数学模型以及液容液感抵抗液压冲击的数学模型,在此基础上借助AMESim进行仿真,验证数学模型的正确性,最后在Solidworks中对AMESim中仿真时用到的液压系统进行三维装配。

本文的研究成果表明,虽然管道的直径越小,产生的液压冲击越大,但是随着管道直径的变小,液压管道抵抗液压冲击的效果也随之变小。在设计液压系统的管道时,为了利用管道的感性和容性消除液压冲击,设计者应权衡利弊,设置合理的管道参数,使得管道既能有效地消除液压冲击,又不至于存在过大的液压冲击峰值。

关键词:液压冲击;液容;液感;管道

Abstract

Hydraulic transmission compared to other small, can easily achieve stepless speed, simple operation and easy to implement overload protection, etc., it is widely used in today's industrialization. However, due to its own characteristics of the hydraulic system, hydraulic impact of its existence is inevitable. Similar to the electrical system, hydraulic system, there are also inertial element, namely a sense of liquid and liquid capacity, inductance and capacitance, as they have inductive and capacitive properties. Because of its physical nature, a sense of liquid and liquid content can effectively resist hydraulic shock generated in the hydraulic system, and a sense of liquid and liquid content is closely related to the parameters of the pipeline Based on the above ideas, this paper studies on a specific hydraulic system, how to set reasonable parameters of pipeline to be able to effectively resist hydraulic shock due to the rapid opening and closing of the valve caused. This article first method uses mathematical calculations derived hydraulic fluid capacity and fluid feeling the impact of the mathematical model and the fluid being liquid capacity to resist hydraulic shock mathematical model on the basis of the aid AMESim simulation to verify the correctness of the mathematical model, and finally Solidworks in the hydraulic system in AMESim simulation used in the three-dimensional assembly.

Results of this study show that, although the smaller the diameter of the pipe, the greater the resulting hydraulic impact, but with smaller diameter pipe, hydraulic pipe hydraulic shock resistance effect also will be smaller. In the design of the hydraulic system piping, in order to take advantage of inductive and capacitive pipeline eliminate hydraulic shock, the designer should be weighed, set reasonable parameters of the pipeline so that the pipeline can effectively eliminate hydraulic shock, but not so the existence of an excessive hydraulic peak shock.

Key Words:Hydraulic shock;Fluid container;Fluid inductance;pipeline

目 录

第1章 绪论 1

1.1液压传动及液压冲击 1

1.1.1液压传动的简介 1

1.1.2液压冲击的简介 1

1.2国内外研究现状 2

1.2.1国外研究现状 2

1.2.2国内研究现状 2

1.3研究意义及内容 3

1.3.1研究意义 3

1.3.2研究内容 3

第2章 液容液感概述及数学模型的推导 5

2.1 液压冲击的计算 5

2.1.1一般系统液压冲击的估算 5

2.1.2某一特定系统液压冲击峰值的计算 6

2.2液压系统的阻抗 7

2.2.1液感的认识 8

2.2.2液容的认识 9

2.3利用液容和液感消除液压冲击的数学模型 11

2.4本章小结 13

第3章 基于AMESim的管道仿真 14

3.1AMESim软件简介 14

3.2基于AMESim的管道仿真 14

3.3基于Solidworks的仿真系统装配 22

3.4本章小结 23

第4章 总结与展望 24

4.1总结 24

4.2不足和展望 24

参考文献 26

致 谢 27