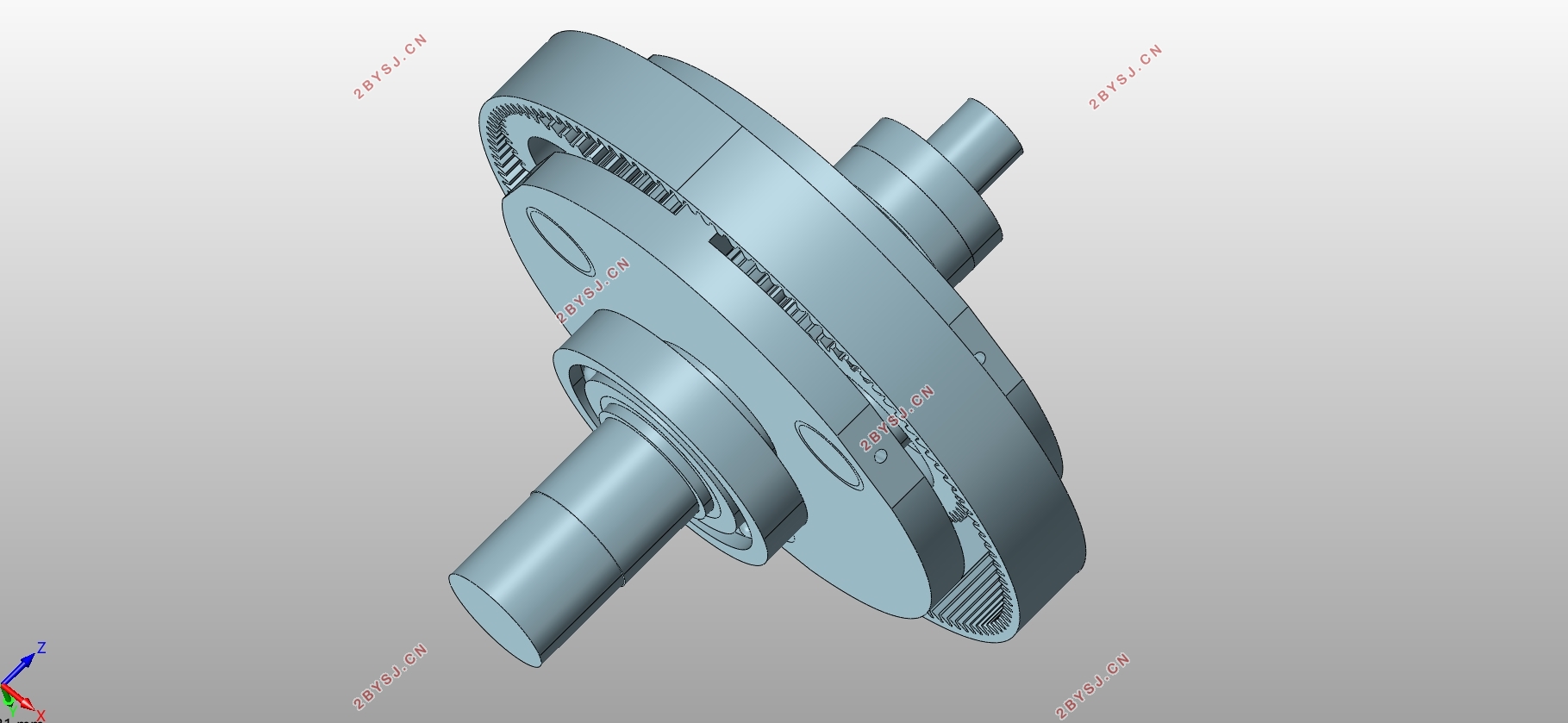

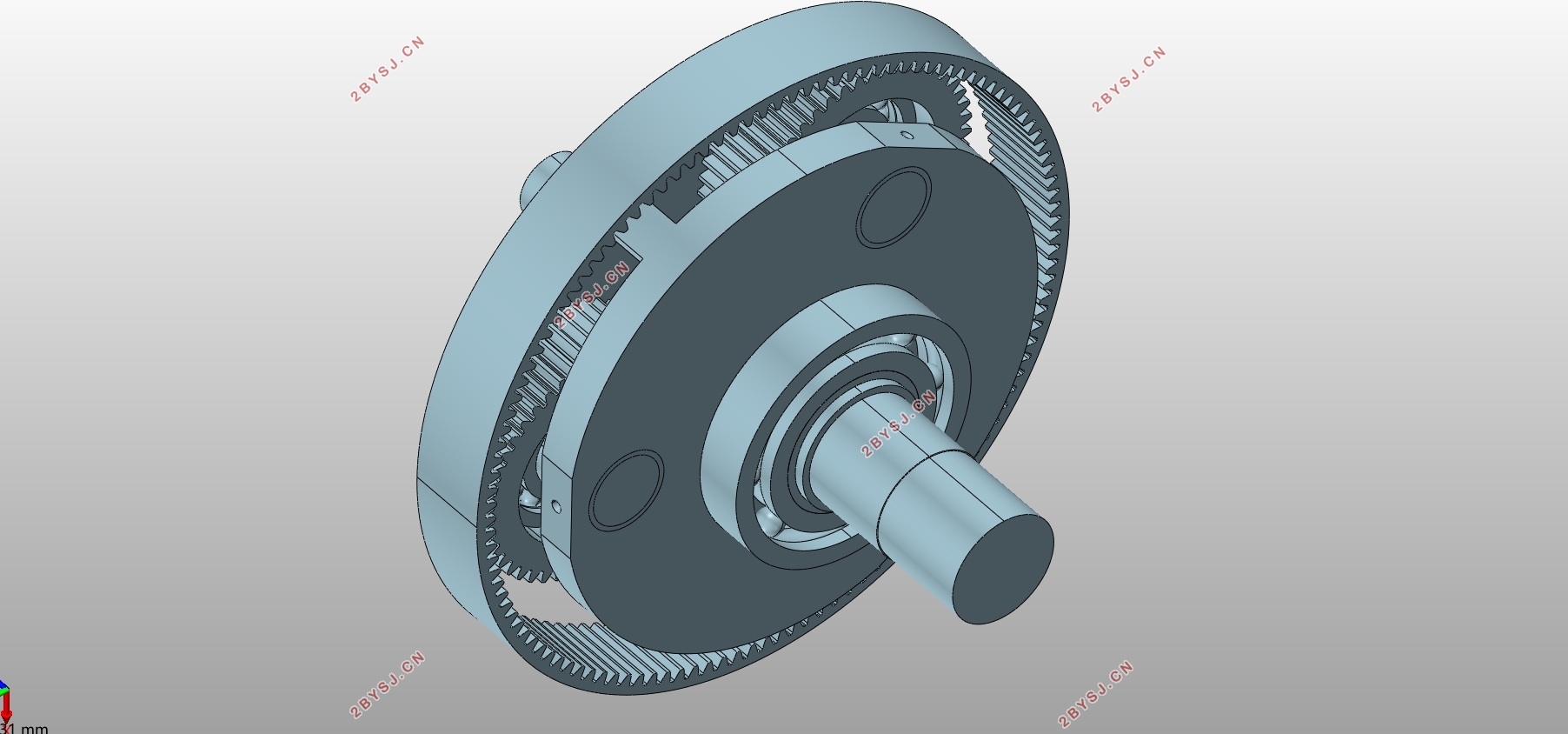

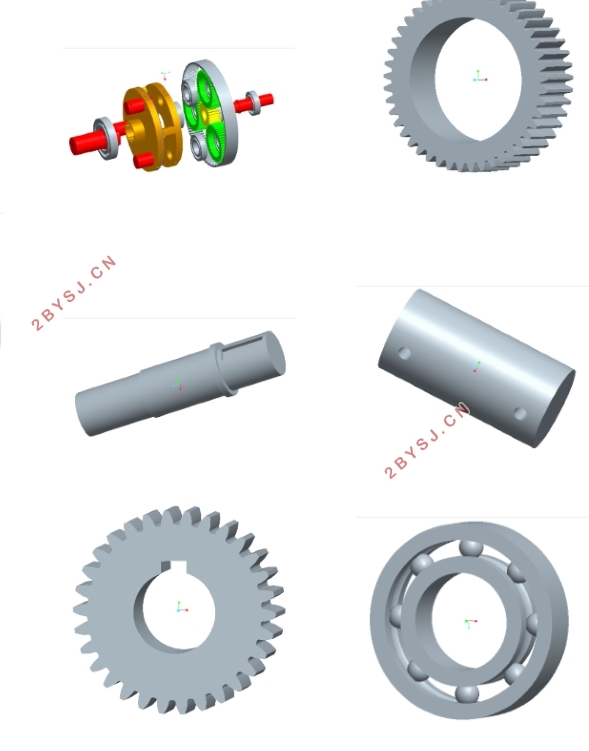

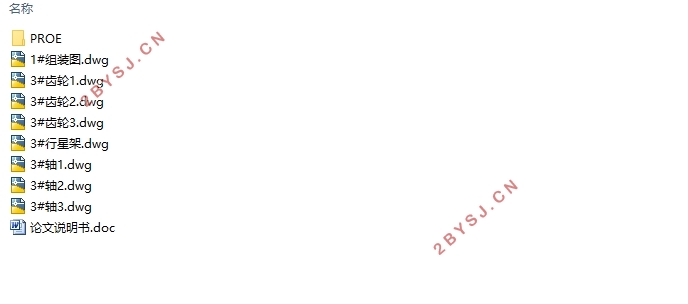

减速器的齿轮和传动轴的设计(含CAD零件图装配图,PROE三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

减速器的齿轮和传动轴的设计(含CAD零件图装配图,PROE三维图)(论文说明书11000字,CAD图8张,PROE三维装配图)

摘要

目前,我们仍主要使用传统的设计方法进行机械零件的设计,在设计过程中甚至产品的使用过程中,我们不难发现,传统的设计方法并不能完全预测零部件可靠运行。因此,合理的机械零件设计及可靠性分析具有十分重要的意义。

机械零件可靠性设计,由于参数本身的特点,得到的信息有限,难以确定其分布函数。同时,概率模型和模糊模型需要大量的数据来确定参数的概率分布或隶属函数,计算量大。研究还发现,概率可靠性对概率模型参数很敏感,微小误差可能对可靠性计算产生很大的影响。这说明在缺乏足够数据信息的情况下,概率可靠性计算的不可信。采用区间理论,能较好地解决上述困难。基于不确定的区间理论,将有边界限制的机械零件参数用区间模型来描述。通过泰勒级数展开等方法对机械零件进行非概率可靠性设计。计算结果表明,常规压力容器设计结果的安全,采用非概率可靠性设计方法可以获得轻量化的结果。

本文对减速器的齿轮和传动轴进行非概率设计,主要研究内容如下:

(1) 比较区间基本理论和非概率可靠性理论下的泰勒级数展开法与常规设计结果,并将其运用到工程实际。

(2) 根据压力容器设计理论,利用泰勒级数展开等方法对压力容器法兰面间的螺栓进行非概率可靠性设计,分析比较各设计计算结果,选择理想的计算方法。

(3)运用泰勒级数展开方法对减速器齿轮和轴进行非概率可靠性设计,得到齿轮和轴的直径;同时,将泰勒级数展开法和常规设计对各结果进行分析比较。

关键词: 机械零件 非概率可靠性 区间理论 泰勒级数展开

ABSTRACT

Currently, the traditional design methods are still mainly used for mechanical parts. In the product design process and servie process, it is easily found that traditional design methods can not predicte the reliably of components totally. Therefore, the rational design of mechanical parts and reliability analysis is of great significance.

Owing to the characteristics of parameters, the limit information makes distribution function hardly to be obtained in the probabilistic reliability design of mechanical parts.However, probabilistic models and fuzzy models need large amounts of data to determine probability distributions or membership functions. It has been found that probabilistic reliability is sensitive to the parameters of probability models. Subtle change or error would cause a major impact on the calculation of reliability. In the absence of information, this illustrates that calculation of probabilistic reliability is not credible. Non-probabilistic reliability interval method is used to preferably figure out the problem.Based on interval theory, uncertain parameters, as mechanical parts would be described by interval model.Non-probability method is proposed for non-probabilistic reliability design of mechanical parts, which includes Taylor series expansion method optimization algorithm.According to the present result, the design result by rule is safety enough and more light mechanical parts could be designed by non-probabilistic reliability design method.

Non-probabilistic design of gear and drive shaft are presented in this thesis. The research contents are as follows:

(1) The design results by Taylor series expansion method and conventional design method are compared which are based on theory of interval and non-probabilistic reliability. These methods could be applied to practical engineering.

(2) Depending on the pressure vessel design theory, the use of Taylor series expansion method with the non-probabilistic reliability design is used for pressure vessel flange bolts, analysis and comparison of the results were made to select the desired calculation method.

(3) The Taylor series expansion method with non-probabilistic reliability design was used for reducer gears and shafts to obtain the gear and the shaft diameter. At the same time, the results of the Taylor series expansion method and the conventional design analysis are compared.

KEYWORDS Mechanical Parts; Non-probabilistic reliability; Interval theory; Taylor series expansion

目录

摘要 I

ABSTRACT II

第一章 绪论 1

1.1研究背景 1

1.2 非概率可靠性的研究现状 3

1.3 基于区间模型的非概率可靠性指标 4

1.4 基于区间模型的非概率可靠性指标计算 5

1.5论文研究的主要内容和技术路线 6

1.5.1主要研究内容 6

1.5.1关键技术及技术路线 6

第二章 减速器齿轮和轴的设计 8

2.1齿轮设计 8

2.1.1齿宽系数选取 8

2.1.2载荷系数选取 8

2.1.3按照齿根弯曲疲劳强度校核 10

2.1.4齿轮按行星轮结构校核 11

2.1.5齿轮几何尺寸的计算 12

2.2轴的设计 14

2.2.1输入轴的设计 14

2.2.2行星轮轴的设计 15

2.2.3行星架轴的设计 15

第三章 基于区间模型的计算方法 16

3.1引言 16

3.2基于区间理论的计算方法 16

3.2.1泰勒级数展开方法 16

3.3 计算实例 18

3.3.1常规设计计算结果 19

3.3.2泰勒级数展开方法计算结果 19

3.4 结果分析 20

第四章 基于区间理论的减速器齿轮和轴设计 21

4.1 引言 21

4.2齿轮传动非概率可靠性分析 21

4.3轴的非概率可靠性分析 23

4.3.1输入轴的非概率可靠性分析与设计 23

4.3.2行星轮轴的非概率可靠性分析与设计 25

4.3.3行星架轴的非概率可靠性分析与设计 26

4.4实例结果分析 28

第五章 结论与展望 29

5.1 结论 29

5.2 展望 29

参考文献 31

致谢 34