变径接头注射成形工艺与注塑模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

变径接头注射成形工艺与注塑模具设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,论文说明书13000字,CAD图11张)

摘要

在注射成型生产过程中,塑料原料、注射设备和注射所用的模具是三个必不可少的物质条件。在本次变径接头注射成型工艺与模具的设计过程中,所用塑料原料是ABS塑料,而ABS塑料也是热塑性塑料,由于热塑性塑料的注射成型工艺也可称为普通注射成型工艺,所以可以按一般的设计程序进行。以变径接头注射成形工艺与模具设计为例,介绍注射模具的设计方法与流程。首先根据塑料材料与工艺性用Pro-E软件中的模流分析软件对零件进行模流分析,获得实验数据。从试验数据的分析,讨论工艺对塑件质量的影响,从而得到最有工艺参数组合。然后选择注塑机并确定型腔的数目,接着确定成型方案;总体结构设计、分型面设计、浇注系统设计、脱模机构设计、冷却系统设计等。最后进行注塑机工艺参数校核,包括注射量、锁模力、注射应力、模具厚度和注塑机闭合高度等方面。

关键词:模具结构、分型面、浇注系统、脱模机构

abstract

In the process of injection molding, plastic raw materials, injection equipment and injection mold are three necessary conditions for the material. In the changeable diameter joint injection molding process and mold design process, the plastic raw material is ABS plastic, ABS plastics and thermoplastic plastics, the thermoplastic plastic injection molding process can also be referred to as the ordinary injection molding process, so it can be carried out according to the general design procedure. With a variable diameter joint injection molding process and die design as an example, introduces the design method and process of injection mold. According to the plastic materials and the process of using Pro-E software, the flow analysis of the parts is carried out, and the experimental data are obtained. From the analysis of the test data, the influence of the process on the quality of plastic parts is discussed, and the combination of the process parameters is obtained. Then select the injection molding machine and determine the number of cavity, and then determine the shape of the program; overall structure design, sub surface design, gating system design, mold release mechanism design, cooling system design, etc.. At last, the process parameters of the injection molding machine were checked, including the injection quantity, the clamping force, the injection stress, the thickness of the mold and the height of the injection molding machine.

Key words:overall structure, parting surface, gating system, ejection mechanism

2.1 塑件形状与成分分析

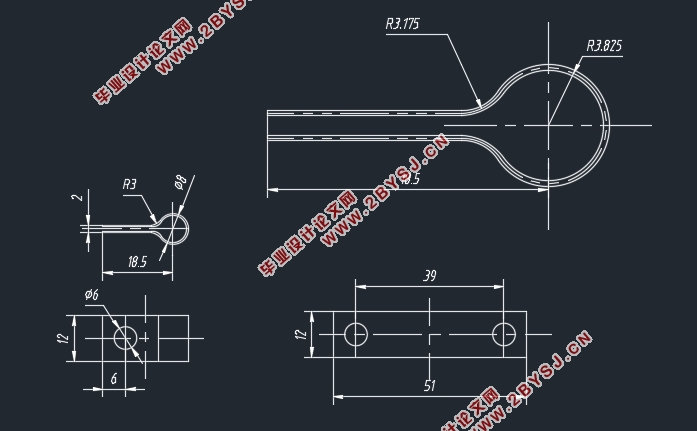

所示的是某种产品上的接头零件,这个塑料制品是一个连接零件,塑料制品的材料是ABS塑料,苯乙烯-丁二烯-丙烯晴共聚物,看上去此塑料件并不复杂,但是有一些需要我们注意:

2.3 塑件的结构分析

该塑件是变径接头,该塑件圆形中空对称件,故在塑件的上侧壁设置侧浇口,以便于塑料熔体充满型腔。由于塑件拥有环形凸台,需要进行侧向分型,结构较为复杂,但又由于塑件的单件质量较小,为保证注射机内塑料熔体的材料利用率,因此采用一模四腔结构。

2.4 塑件的尺寸精度分析

由图2.1 塑料制件尺寸图分析可见,此次注塑件并没有具体的精度要求,因此取最低精度8级。由于该塑件的尺寸精度为低精度,通过与之相对应的模具的零件尺寸精度就可以满足塑件的尺寸精度要求。

2.5 塑件的表面质量分析

由任务书可知,塑料件没有特别的表面质量要求,因此塑件的标准表面粗糙度要求比较容易实现。从图2.1 塑料制件尺寸图和塑件结构特性分析中可以看出,注射成型质量时在工艺参数控制得较好的情况下,零件的成型要求可以得到保证。

2.6分型面的设计

在注塑模中,分型面被用于取出塑件和浇注系统的凝料。分型面的选择要求有:应该有利于塑件的脱模,减小塑件的脱模阻力,以保证模具的使用寿命;能够保证塑件的结构质量,避免合模后出现较大的形状尺寸偏差;有利于防止溢料,以便模腔内气体的排出;尽量使成型零件便于加工,降低模具的加工难度;尽量避免形成侧孔、侧凹,用以简化模具的结构;应不影响塑件制品的外观,优先选择在不破坏塑件表面质量的部位;尽量减小脱模斜度给制品大小端尺寸带来的差异,减小塑件的尺寸误差;要能使塑件从模具中顺利取出。

目录

第1章 绪论...................................................................................................................................1

1.1 塑料与塑料制品................................................................................................................1

1.2 塑料成型技术的发展........................................................................................................1

1.2.1 塑料制品成型方法................................................................................................1

1.2.2 塑料成型技术的发展............................................................................................2

1.3 塑料成型模具及发展趋势................................................................................................2

1.3.1塑料模具在塑料成型中的重要性.........................................................................2

1.3.2 我国的塑料模具水平............................................................................................3

1.3.3 塑料模具的发展趋势............................................................................................3

1.4 毕业设计选题的背景、目的和意义................................................................................3

1.4.1 毕业设计选题的背景............................................................................................3

1.4.2 毕业设计的目的和意义........................................................................................4

第2章 塑件分析...........................................................................................................................5

2.1 塑件形状与成分分析........................................................................................................5

2.2 塑件体积与质量的计算....................................................................................................6

2.3 塑件的结构分析................................................................................................................7

2.4 塑件的尺寸精度分析........................................................................................................7

2.5 塑件的表面质量分析........................................................................................................7

2.6 分型面的设计....................................................................................................................7

2.8 排气槽的设计....................................................................................................................8

第3章 注射机的选用与校核.......................................................................................................9

3.1 型腔数目的确定................................................................................................................9

3.2 注射机的选用....................................................................................................................9

3.3 注射机的校核..................................................................................................................10

3.3.1 最大注射量的校核..............................................................................................10

3.3.2 注射压力的校核..................................................................................................10

3.3.3 锁模力的校核......................................................................................................11

3.3.4 注射机行程的校核..............................................................................................12

第4章 浇注系统的设计.............................................................................................................13

4.1 主流道结构尺寸设计 ....................................................................................................13

4.2 浇口套与定位圈的设计..................................................................................................13

4.3 分流道的设计..................................................................................................................14

4.4 浇口设计..........................................................................................................................15

第5章 成型零部件的设计.........................................................................................................17

5.1 成型零件的结构..............................................................................................................17

5.1.1 凹模的结构...........................................................................................................17

5.1.2 型芯的结构...........................................................................................................17

5.2 成型零件工作尺寸的计算..............................................................................................18

5.2.1 型腔的径向尺寸...................................................................................................19

5.2.2 型芯的径向尺寸...................................................................................................19

5.2.3 凹模的深度尺寸...................................................................................................19

5.2.4 型芯的高度尺寸...................................................................................................19

5.3 凹模侧壁强度的校核......................................................................................................20

第6章 基本结构零件设计及标准模架.....................................................................................21

6.1 合模导向机构设计..........................................................................................................21

6.1.1 导柱的选择...........................................................................................................21

6.1.2 导套的选择...........................................................................................................21

6.2 支承固定零件设计..........................................................................................................21

6.3 塑料模具的标准化及标准模架的选用..........................................................................22

第7章 脱模机构与侧向分型机构的设计.................................................................................23

7.1 脱模力的计算..................................................................................................................23

7.2 推出零件尺寸的确定......................................................................................................24

7.3 斜滑块式侧向分型机构的设计......................................................................................24

第8章 温度调节系统的设计.....................................................................................................26

8.1 模具温度调节系统的作用..............................................................................................26

8.2 冷却系统的计算..............................................................................................................26

8.2.1 塑料传给模具的热量...........................................................................................26

8.2.2 模具散发出的热量...............................................................................................27

第9章、变径接头注射模具总装设计图...................................................................................29

第10章、结论.............................................................................................................................30

致谢...............................................................................................................................................31

参考文献.......................................................................................................................................32