柴油机曲轴加工工艺及检具设计(含CAD图,工艺卡)

无需注册登录,支付后按照提示操作即可获取该资料.

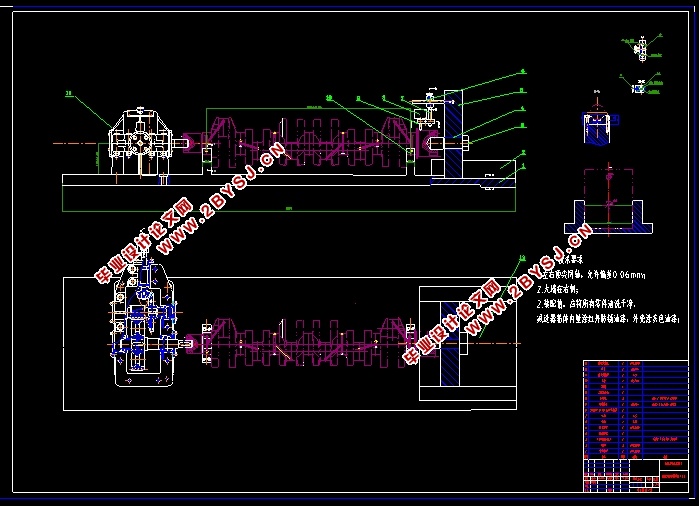

柴油机曲轴加工工艺及检具设计(含CAD图,工艺卡)(论文说明书12000字,外文翻译,CAD图4张,工艺卡)

摘要

本次设计的题目是柴油机曲轴加工工艺及检具设计。曲轴在发动机中承受冲击载荷和传递动力的作用。曲轴是连接连杆的部件,将活塞往复转化为旋转运动,是发动机的关键部件。曲轴加工质量将直接影响柴油机的工作性能。

曲轴的精度有严格的要求,需要设计加工工艺和专用的检具。在加工工艺部分,需要排工艺路线、确定工艺顺序、计算工序尺寸、安排热处理工艺及表面处理工艺、确定毛坯尺寸、选择加工方法;编写工艺规程卡、工序过程卡、工序卡。检具设计为主轴颈径向圆跳动专用检具。分析误差要求即主轴颈圆跳动0.025;绘制圆跳动检具装配图和主要的零件图;检具是通过动力源带动曲轴转动,传感器在曲轴上读取数值。数据采集方法选用探针型检测方法,进行数据采点。其传感器选择离最远端30cm处,在其截面上测取60个数值并对其进行数据处理。其误差评定方法分别采用最大值最小值和平均值法,分别用c语言进行编程,程序可靠。

关键词:曲轴,加工工艺,检测技术

ABSTRACT

The topic of this design is diesel crankshaft processing technology and fixture design. The crankshaft bears the impact load and the transmission power in the engine. The crankshaft is a component connecting the connecting rod. It transforms the piston into rotary motion and is the key component of the engine. Crankshaft machining quality will directly affect the performance of diesel engine. The precision of crankshaft is very strict, and the design process and special fixture are needed. In the process part, it is necessary to arrange the process route, determine the sequence of the process, calculate the size of the process, arrange the heat treatment process and surface treatment process, determine the size of the blank and select the processing method, and write the process card, process card and process card. The fixture is designed as a special fixture for the radial circle beating of the spindle neck. The requirement of the analysis error is 0.025 of the circle of the spindle neck; the assembly drawing and the main part drawing are drawn. The device drives the crankshaft to rotate through the power source, and the sensor reads the value on the crankshaft. The data acquisition method uses probe type detection method and data acquisition point. The sensor is selected from the far end 30cm, and 60 values are measured on the cross section and processed. The method of error evaluation adopts the maximum and minimum value method respectively, and is programmed in C language, and the program is reliable.

Keywords:Crankshaft, Processing technology,Testing technology

目录

摘要………………………………………………………………………………………………………….I

ABSTRACT…………………………………………………………………………………………………...II

1.绪论……………………………………………………………………………………………………….1

1.1柴油机曲轴的作用 1

1.2目前研究的概况和发展趋势 1

1.3国内外曲轴加工技术展望 1

1.4重点解决的问题 2

2.柴油机曲轴分析及参数说明 3

3.曲轴机械加工工艺规程设计 4

3.1年生产量和批量的确定 4

3.2曲轴定位基准的选择 4

3.3曲轴加工工艺 4

3.4曲轴工艺路线的拟定 5

3.5曲轴主要工序所用机床和设备确定 6

3.6曲轴加工工序尺寸的确定 7

3.7工艺卡填写 13

4.曲轴主轴颈圆跳动检具设计 16

4.1 检具设计要求 16

4.2 检具总体结构及工作原理 16

4.3 检具主要零部件设计 19

5.圆跳动数据采集与处理 27

5.1数据采集方法 27

5.2数据处理程序 28

6.结论 30

参考文献 31

附录1外文译文 32

附录2外文原文 35

致谢………………………………………………………………………………………………………...39