EQ1092F8AD1型长头柴油载货汽车后悬设计(英文版)(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

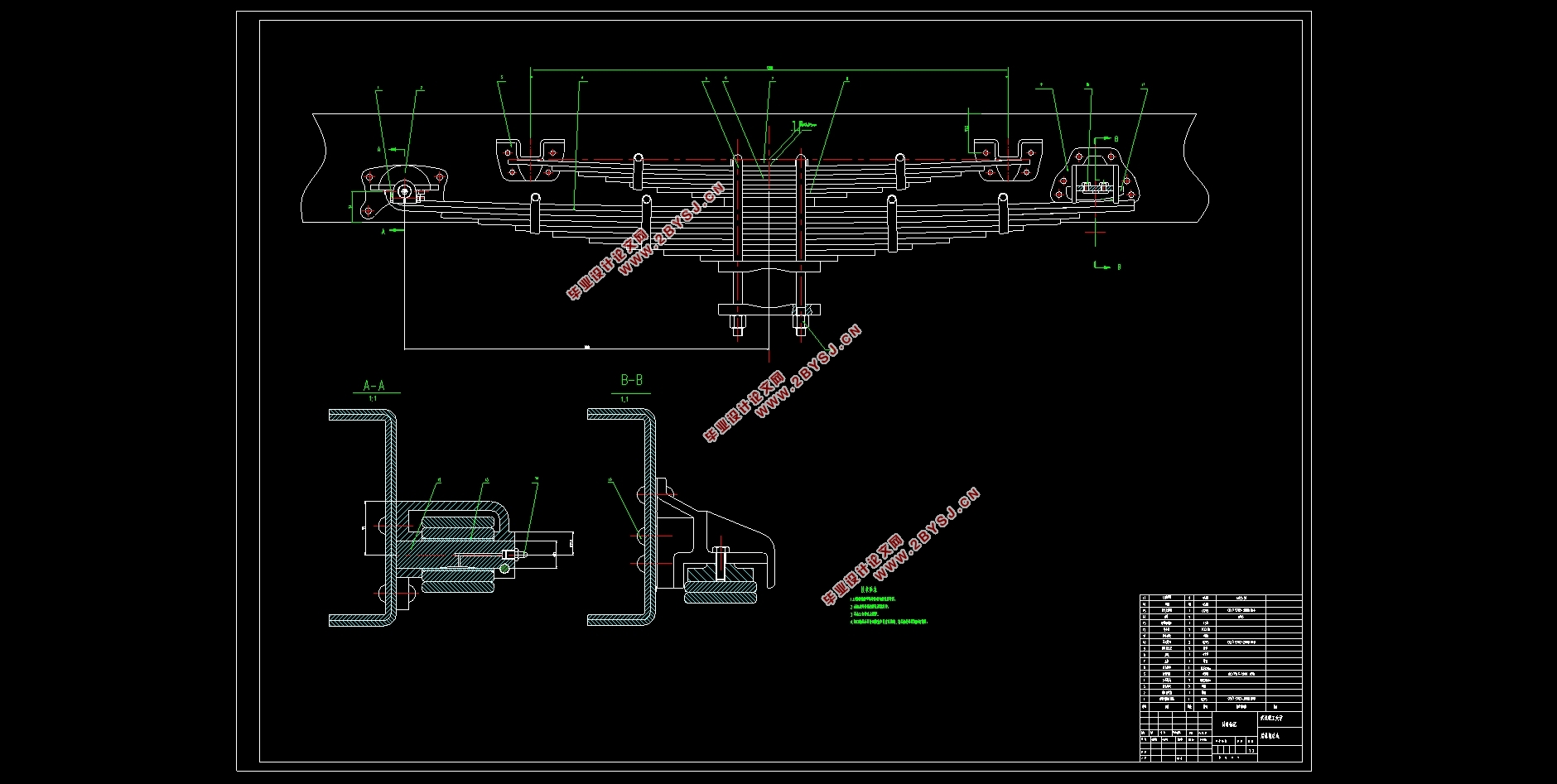

EQ1092F8AD1型长头柴油载货汽车后悬设计(英文版)(含CAD图)(任务书,开题报告,外文翻译,文献摘要,论文说明书英文版8700字,CAD图4张)

Rear suspension design of dongfeng long-head diesel truck, model EQ1092F8AD1

Abstract

My graduation design theme is the rear suspension design of dongfeng long-head diesel truck, model EQ1092F8AD1.

At present, the trucks listed in China mainly use non-independent suspension.The first step is to determine the structure of the rear suspension, and then select and calculate the main parameters of the suspension.Because there are many differences in the structural functions of the front and rear suspension, the most obvious difference between the rear suspension and the front suspension in the design process is that the rear suspension needs to distribute the stiffness of the main and auxiliary springs. After calculation, the stiffness distribution of the main spring and the auxiliary spring is represented by the elastic characteristic diagram.In addition, the main and auxiliary spring should be calculated separately to determine the main parameters, determine the length of each piece, check the strength, and calculate the assembly radius of curvature and arc height.

As the elastic component of the target suspension, leaf spring is the most important part in the design of truck suspension, which is of great significance to the driving and riding comfort, ride comfort, vibration reduction ability and suspension structure.

Key words: EQ1092F8AD1leaf spring independent suspension

Content

1 Introduction 1

2 Determine the Basic Parameters of the Truck 2

2.1 Main design parameters 2

2.2 Number of axles of the truck 2

2.3 Driving type 2

2.4 Layout 2

2.5 Main dimensions of goods vehicles 3

2.5.1 Overall dimensions 3

2.5.2 Wheelbase L 4

2.5.3 Front and rear wheelbase 4

2.5.4 front suspension and rear suspension of the automobile 5

2.6 Truck quality parameters and axle load distribution 5

2.6.1 Vehicle readiness quality 5

2.6.2 Loading quality 5

2.6.3 Truck quality coefficient 6

2.6.4 Total mass of truck 6

2.6.5 Axis load distribution 6

2.6.6 height h of the center of mass of the truck 7

3 Determination of basic parameters of rear leaf spring suspension 8

3.1 suspension static deflection 8

3.2 Suspension dynamic deflection 9

3.3 Elastic characteristics of the suspension 9

3.4 Stiffness distribution of main and auxiliary springs of rear suspension 10

3.5 Selection of main parts and components of the suspension system 12

3.5.1 Connection form between leaf spring and frame 12

3.5.2 Spring clamp 12

3.5.3 leaf spring center bolt 12

4 Design of elastic components 14

4.1 layout of leaf springs 14

4.2 Determination of main parameters of leaf spring 14

4.2.1 Full arc height 15

4.2.2 Determination of leaf spring length L 15

4.2.3 Determination of section size and number of steel plates 16

4.3 Determination of leaf spring length 18

4.4 Determination of bearing type of leaf spring end 19

5 Conclusion 26

Reference 27

Appendix A 28

Appendix B 29