螺母注塑模设计(含cad零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

螺母注塑模设计(含cad零件图和装配图)(含任务书,开题报告,论文说明书9500字,CAD图纸8张)

摘要

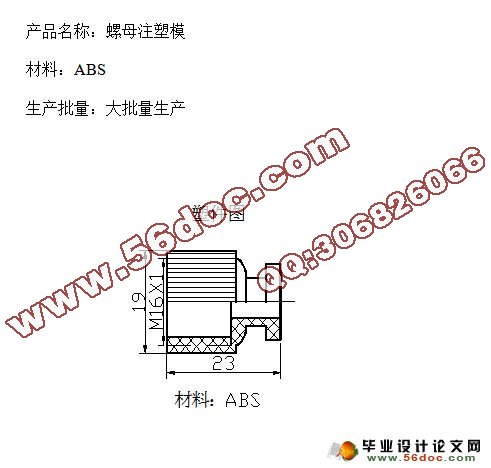

根据螺母的生产批量、ABS的性能特点和螺母的结构特点,设计螺母注塑模。螺母为通用零件,精度要求不高,但由于结构原因,需要成型侧环形凹槽,和成型内部螺纹,使模具结构相对复杂,增加了装配时的难度。为成型环形凹槽,模具采用了斜导柱侧向抽芯机构,为便于螺纹型芯的抽出,模具整体为直角式注塑模,与此相对应才用直角式注塑机,由与塑件对精度要求不高,成型零件加工较为容易

本模具采用一模两腔,总体上该模具机构简单,制造容易,生产周期短,节约了企业成本,缩短了制模周期。

关键词:环形凹槽 侧向抽芯 直角式注塑模

(The mould of nut)

Abstract

According to the structure characteristics of functio characteristics and nut mother of the nut mother's production batch quantity, ABS, design nut the mother notes the mold of plastik .The mother of the nut is an in general use spare parts, the accuracy have not high request, but because of the structure reason, need to model the cave slot of the side wreath form, and model the internal thread, making the molding tool structure opposite complications, increased the assemble the difficulty of the hour.In order to model the cave slot of the wreath form, the molding tool adopted inclined lead the pillar side to take out the organization of 芯 , draw out for a core of easy to thread, the molding tool is whole to note the mold of plastic for the right angle type, with this opposite at the request of just note the machine of plastic with the right angle type, from with piece of plastic to the accuracy not high, model the spare parts to process more easy

This molding tool adopts two antrums of one mold, total ascend that molding tool organization simple, make easily, produce the period short, economized the business enterprise cost, shorten to make the mold period.

Keyword:Cave slot side of the wreath form to take out the core right angle type to note the mold of plastic

Keyword:a cave slot of wreath . side to take out the core . the right angle type notes the mold of plastic.

目录

1绪论…………………………………………………………… 4

2模具工艺规程的制定…………………………………………… 6

3 注塑模的结构设计 ……………………………………………...8

4 模具设计的有关计算 ………………………………………......13

5 模具加热与冷却系统的计算 …………………………………...15

6结构与辅助零部件的设计………………………………………..18

7模具闭合高度的确定 ………………………………………..19

8注塑机有关参数的校核 ………………………………………20

9模具的装配与调试 …… ………………………………….....16

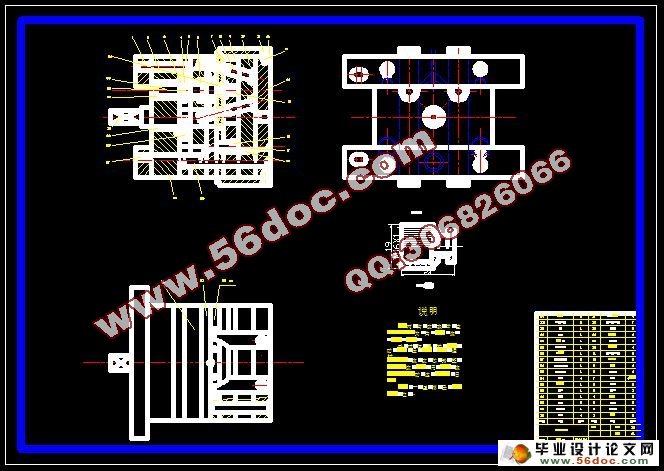

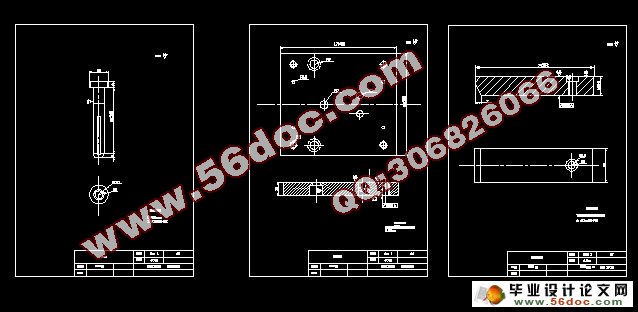

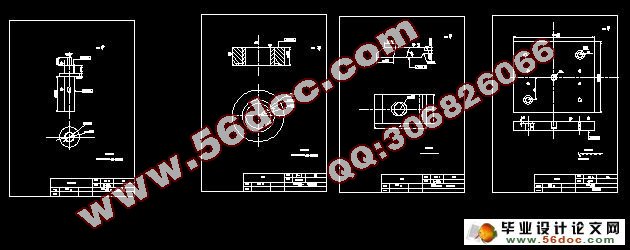

10制模具总装配图和非标零件图………..……………………......24

11塑模主要零件加工工艺规程的编制………………………........ 25

12结论………………………………………………………….. …….26

13致谢 ……………………………………………………………….27

14参考文献 ………………………………………………………….28

插图清单

图1-1 螺母零件图

图1-2 分型面的选择

图1-3 型腔的排列方式

图1-4 导柱的形式

图1-5 导套的形式

图1-6 凸模结构

图1-7 凹模结构

卡1型芯加工工艺卡

卡2型腔加工工艺卡