正装下顶出单工序落料模的设计(含cad零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

正装下顶出单工序落料模的设计(含cad零件图和装配图)(含任务书,设计说明书11000字,CAD图纸8张)

摘要

冲压模具作为制造产品(或半产品)的一种工具,其作用是完成某种工艺。模具设计必须满足工艺要求,最终满足产品的形状、尺寸和精度的要求。因此冲压设计师必须掌握冲压工艺,包括冲压工艺的分类、各种工艺计算、工艺制订等基础知识,而后才可以选择模具的类型,进行模具设计,使模具的类型表面质量、尺寸精度结构及尺寸等满足工艺及产品的要求。

冷冲压工艺大致分两类:分离工序和成型工序。分离工序的目的是在冲压过程中将冲压件与板料按一定的轮廓线进行分离:分离工序又可分为落料、冲孔和剪切等。成型工序的目的是使冲压毛胚在不破坏其完整性的条件下产生塑性变形,并转化成产品所需要的形状:成形工序又分为弯曲、拉深、翻边、翻孔、胀形、扩孔等。

冷冲压模具是冲压生产的主要工艺设备。冲压件的表面质量、尺寸精度、生产率以及经济效益等,与模具结构及设计是否合理关系极大。

关键词: 落料、塑性变形、工艺计算、工艺制订、表面质量、尺寸精度

Just pack a single work preface to fall to anticipate the mold

Abstract

Hurtle a kind of tool of press the molding tool conduct and actions manufacturing product( or the half product), its function is to complete a certain craft. Therefore hurtling to press designer must control to hurtle to press the craft, the classification, various craft calculation, craft that includes to hurtle to press the craft establishes etc. the foundation knowledge, just can choose the type of the molding tool and then, carry on the molding tool design, make the type, structure and size etc. of the molding tool satisfy the request of the craft and product.

Cold hurtle to press the craft to divide mostly two type: Separate the work preface and model the work preface. Purpose that separates the work preface is at hurtle to ran over the distance lieutenant general to hurtle to press the piece and planks to anticipate to press certain outline line to carry on the separation: Separating the work preface can is divided in to fall to anticipate again, blunt bore and shear to slice etc.. The purpose that models the work preface is to make hurtle to press the hair , the creation transforms under the condition of not break its integrity, and convert the shape that product need: Take shape the work preface and is divided into the flection and pull deep, turn over the side, turn over the bore, bulge form and expand the bore, etc.. Cold hurtle to press the molding tool is main craft equipments that hurtles to press to produce. Hurtle the surface quantity, size accuracy, rate of production and the economy performance etc. of press the piece, with the molding tool structure and designs whether the reasonable relation is biggest.

Keyword: Fall to anticipate, plastic deformation, the craft calculation, craft establish, surface quantity, size accuracy

目录

绪论

插图清单

表格清单

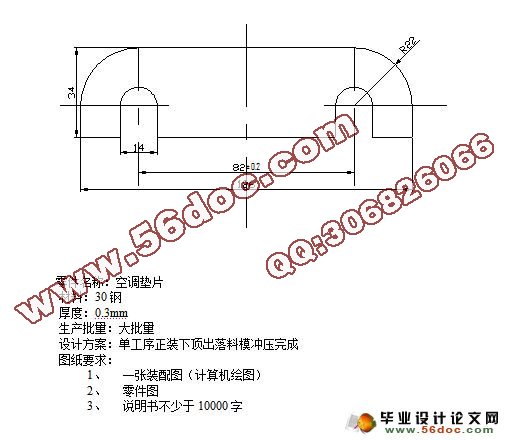

第1章 设计内容及要求………………………………………………….1

1.1 制件图、材料及要求…………………………………………………………….1

第2章 冲裁工艺的分析……………………………………………………2

第3章 主要设计计算………………………………………………………3

3.1 排样方式的确定………………………………………………………………….3

3.2 毛胚的确定……………………………………………………………………….3

3.3 冲裁力的计算…………………………………………………………………… 3

3.3.1 冲裁力………………………………………………………………………………… 3

3.3.2 压力中心的确定及相关尺寸的计算……………………………………………………4

3.4 工作零件刃口尺寸的计算…………………………………………………… 5--6

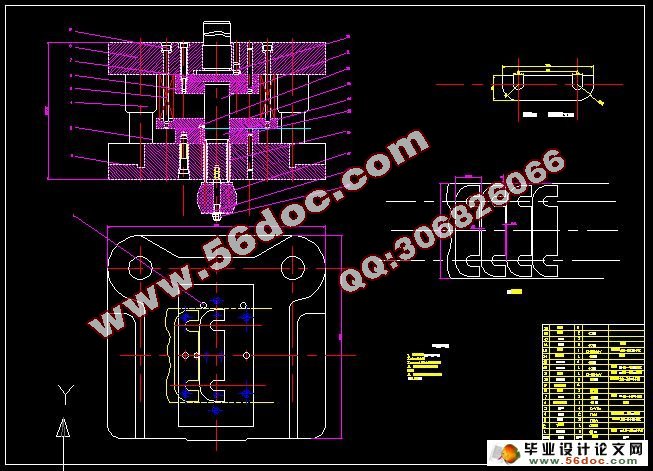

第4章 模具总体设计及主要零部件设计……………………………… 7

4.1 模具结构的选择………………………………………………………………… 7

4.2 卸料弹簧的设计与计算………………………………………………………… 7

4.3 冲压设备的选择………………………………………………………………… 8

4.4 模具总体的设计………………………………………………………………… 8

4.4.1 模具类型的选择………………………………………………………………………… 8

4.4.2 定位方式的选择………………………………………………………………………… .8

4.4.3 导向方式的选择…………………………………………………………………………..8

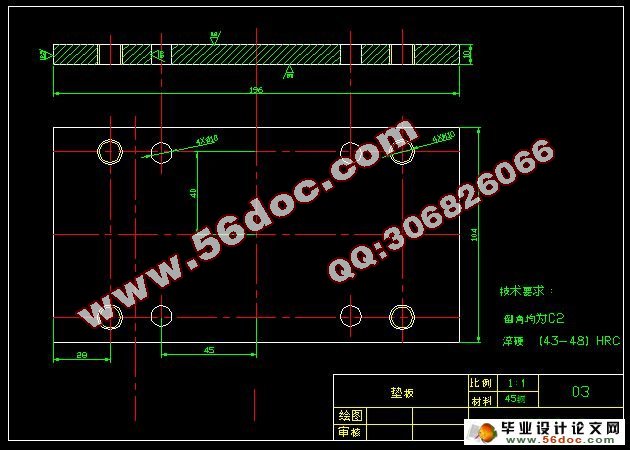

4.5 主要零部件的设计……………………………………………………………….8

4.5.1 工作零件的结构设计………………………………………………………………………8

4.5.2 落料凸模的设计…………………………………………………………………………….9

4.5.3 落料凹模的设计…………………………………………………………………………… 9

4.5.4 定位零件的设计…………………………………………………………………………….9

4.6 卸料部件的设计…………………………………………………………………10

4.6.1 卸料板的设计………………………………………………………………………………11

4.6.2 卸料螺钉的选用……………………………………………………………………………11

4.6.3 顶件装置……………………………………………………………………………………11

4.7 模具总装图……………………………………………………………………….11

4.8 模具工作零件的加工工艺……………………………………………………….11

第5章 模具的装配与调整……………………………………………….12

5.1 主要配件的装配………………………………………………………………...12

5.1.1 模柄的装配…………………………………………………………………………...12

5.1.2 凸模的装配……………………………………………………………………………12

5.1.3 弹压卸料板的装配…………………………………………………………………….12

5.2 总装图…………………………………………………………………………… 13

5.3 冲裁模试冲的缺陷和调整…………………………………………………..13--14

第6章 结论………………………………………………………………….15

致谢………………………………………………………………… 16

参考文献……………………………………………………………17

附录…………………………………………………………………18