中轴碗冲压成形工艺与模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

中轴碗冲压成形工艺与模具设计(含CAD零件图装配图)(任务书,中期检查表,论文说明书8000字,工艺卡工序卡,CAD图14张)

摘 要

本设计题目为中轴碗冲压成形工艺与模具设计,体现了板类冲压零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲压模具设计的基础知识,为设计更复杂的冲压模具做好了铺垫并吸取了更深刻的经验。

本设计运用冲压成型工艺及模具设计的基础知识,首先分析了工件的成形工艺及模具成形结构对制件质量的影响。介绍了中轴碗冲压模具设计时要注意的要点,通过对制件进行工艺分析,可确定制件的成形加工用一套复合模和一套冲孔模具即可。从控制制件尺寸精度出发,对中轴碗冲压模具的各主要尺寸进行了理论计算,以确定各工作零件的尺寸,从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:复合模 工艺分析 模具零部件的加工工艺

the center bowl stamps forminghandicraft and design for die

Abstract

The topic of this design is the center bowl stamps forming handicraft and design for die.The requirement,content and direction of the design of the stamps forming plate parts are embodied on this stamping die design. The designer’s foundation knowledge of the stamping die design is reinforced and is able to design more complex stamping die through the design.

This design the elementary knowledge which designs using the stamping formation craft and the die, first has analyzed the work piece formed craft and the die forming structure to the workpiece quality influence. Introduced the center bowl filling piece stamping die design when must pay attention to the main point, through carries on the craft analysis to the workpiece, may determine the workpiece the formed processing uses set of superposable dies and a punching die. Embarks from the control workpiece size precision, counter center bowl filling piece stamping die each main dimension has carried on the theoretical calculation, by determined each work components the size, designs from the die to the spare part processing craft as well as the assembly craft and so on carries on the detailed elaboration, and carries on each important components using CAD the design.

Key words: compound die;process analysis;processing of die parts.

目 录

1 绪论………………………………………………………………………………1

1.1 国内模具的现状和发展趋势…………………………………………………1

1.1.1国内模具的现状………………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………………2

1.2国外模具的现状和发展趋势……………………………………………………3

1.3 深圆筒拉深模具设计的设计思路……………………………………………4

2 深圆筒件工艺分析………………………………………………………………5

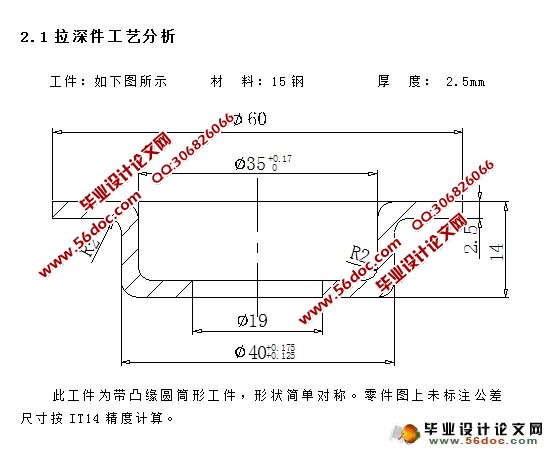

2.1 拉深件的工艺性分析…………………………………………………………5

2.2 拉深工艺计算和工艺方案的确定……………………………………………5

2.2.1 工艺方案的确定………………………………………………………………5

2.3 工艺计算…………………………………………………………………………6

2.3.1 计算毛坯尺寸…………………………………………………………………6

2.3.2 确定工件是否能一次拉深成形………………………………………………6

2.3.3确定是否用压边圈………………………………………………………………6

2.3.4落料排样设计……………………………………………………………………6

2.3.5 主要工作零件的尺寸计算……………………………………………………8

2.3.6 选取凸模与凹模的圆角半径 ………………………………………………11

2.3.7 主要零部件设计………………………………………………………………11

2.4 压力、压力中心计算及压力机的选用………………………………………12

2.4.1 压力计算………………………………………………………………………12

2.4.2 压力机的选用…………………………………………………………………14

3 模具的结构设计…………………………………………………………………16

3.1 选用模架、确定闭合高度及总体尺寸………………………………………16

3.2 其它模具零件的结构设计………………………………………………………17

3.2.1 固定板…………………………………………………………………………17

3.2.2垫板………………………………………………………………………………17

3.2.3 打料块…………………………………………………………………………17

3.2.4压边圈……………………………………………………………………………17

3.2.5 导柱、导套……………………………………………………………………18

3.2.6 其他零件………………………………………………………………………18

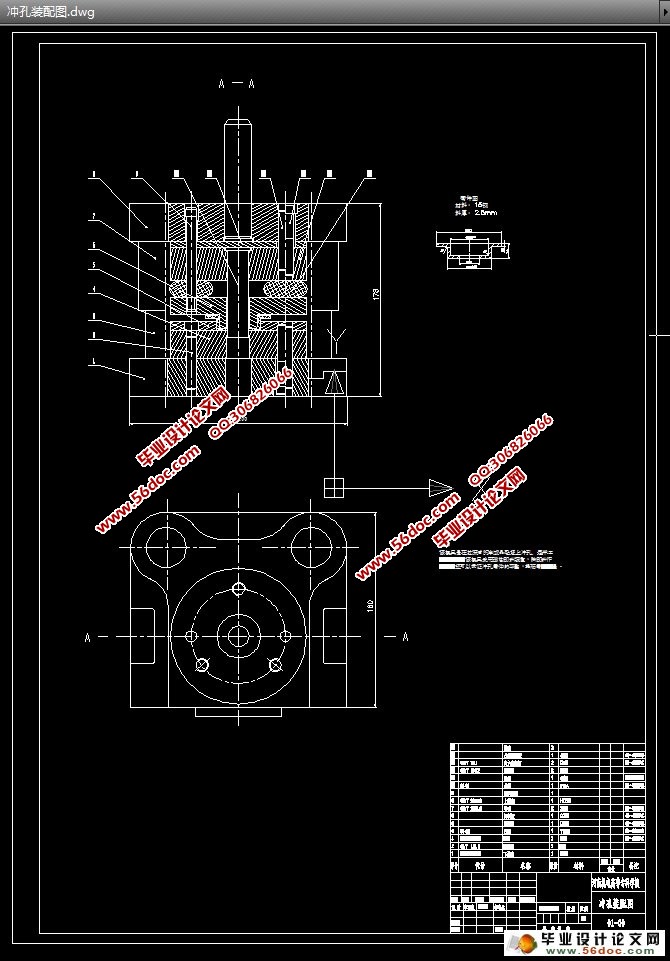

3.3 模具总装图………………………………………………………………………19

4 结束语……………………………………………………………………………20

致谢 …………………………………………………………………………………21

参考文献………………………………………………………………………………23

插图清单

图1制件 …………………………………………………………………………5

图2排样图 ………………………………………………………………………7

插表清单

表一压力机参数表……………………………………………………………14

表二模架规格表 ……………………………………………………………16

表三模具其他零件的选用……………………………………………………18