元器件自动检测系统的设计

无需注册登录,支付后按照提示操作即可获取该资料.

元器件自动检测系统的设计(论文12000字)

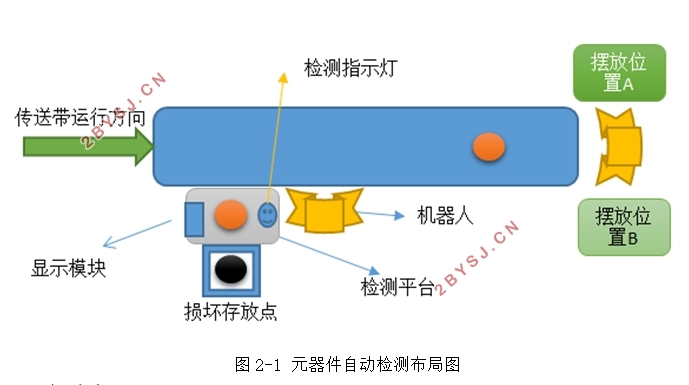

摘要:随着电力电子器件行业在不断的发展,制造工艺越来越复杂,产品的质量需要得到保证,因此需要对元器件进行检测。传统的人为取放检测耗费大量的人力资源,无法满足生产效率的需求,因此需要使用效率较高的机械臂和专业检测工具来实现自动化的生产运行。本文在进行元器件检测系统研究时,将所有的控制都集成到一起,由一个单片机进行控制机械臂,另一个单片机控制检测平台。本文通过机械结构的连接形成三轴的机械臂,将元器件移位到检测平台实现了抓取功能。检测平台设计了对模块式继电器的检测。当继电器抓被取之后放入检测平台后,继电器电路线圈输出结果数据传输到单片机。为了实现检测平台检测结果的清晰明了,利用单片机与液晶屏通讯,实时输出显示处理结果,具体的信息包括好的产品数量和坏的产品数量。

关键词:自动检测,单片机,舵机,控制系统

Design of Automatic Detection System for Components

Abstract: With the continuous development of the power electronic device industry, the manufacturing process is becoming more and more complex, and the product quality needs to be guaranteed, so the components need to be tested. Traditional manual detection of pickup and release consumes a lot of human resources and cannot meet the demand of production efficiency. Therefore, it is necessary to use mechanical arms with high efficiency and professional detection tools to achieve automatic production and operation. In this paper, the components detection system research, all the control is integrated together, by a single chip microcomputer control arm, another single chip microcomputer control detection platform. In this paper, a three-axis mechanical arm is formed through the connection of the mechanical structure, and the components are moved to the detection platform to achieve the grasping function. The detection platform is designed to detect the modular relay. After the relay is caught and put into the detection platform, the relay circuit coil output result data is transmitted to the single-chip microcomputer. In order to achieve the clarity of the detection result of the detection platform, the single-chip microcomputer is used to communicate with the LCD screen, and the real-time output displays the processing results. The specific information includes the number of good products and the number of bad products.

Keywords: automatic detection, single chip microcomputer, steering gear, control system

目 录

1 绪论 1

1.1 研究背景 1

1.2 国内外研究发展现状及趋势 1

1.3 元件自动检测系统的意义 2

1.4 本论文的主要工作及章节安排 2

2 元器件自动检测系统总体设计 3

2.1 自动检测系统的总体设计 3

2.2 机械手臂硬件功能设计 4

2.3 软件功能设计 4

2.4 本章小结 5

3 元器件自动检测系统硬件设计与实现 6

3.1 控制芯片的选型 6

3.1.1单片机的组成及原理 6

3.1.2 单片机的选型 7

3.1.3 单片机的单片机最小系统设计 8

3.2 机械臂模块硬件的设计 8

3.2.1 舵机的类型介绍 8

3.2.2 舵机的控制原理及选择 9

3.2.3 舵机的接线原理图 11

3.3 检测模块的设计 12

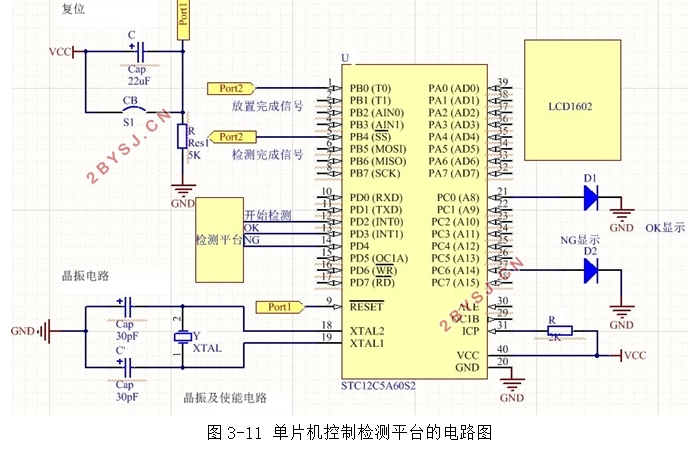

3.3.1 单片机控制检测平台的电路设计 12

3.3.2 元器件检测的电路设计 12

3.4 LCD显示模块的硬件设计与实现 13

3.4.1 LCD显示模块选型 13

3.4.2 LCD1602的原理图 14

3.5 总体电路的设计 14

3.6 本章小结 15

4 元器件自动检测系统软件程序设计 16

4.1 单片机的软件编程 16

4.2 机械臂控制的软件设计 16

4.3 检测模块的软件设计 16

4.4 显示模块的软件设计 17

4.5 本章小结 17

5 系统的硬件组装与调试 18

5.1 系统硬件连接 18

5.2 系统软件测试 18

5.3 硬件运行检测 20

5.4 本章小结 21

第六章 总结 22

参考文献 23

致谢 24