基于汽车卡钳的打磨机器人抓手设计(含CAD图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

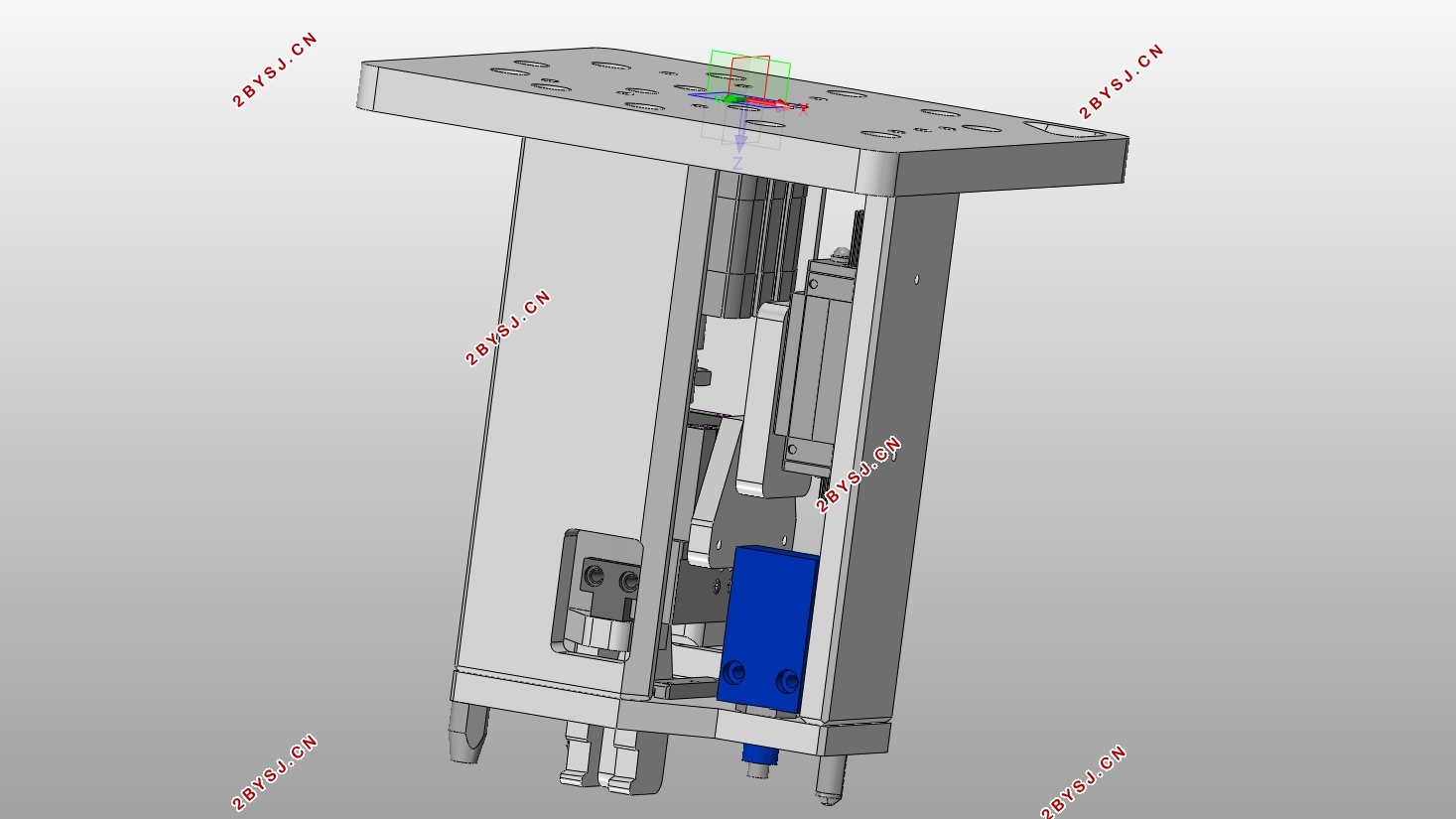

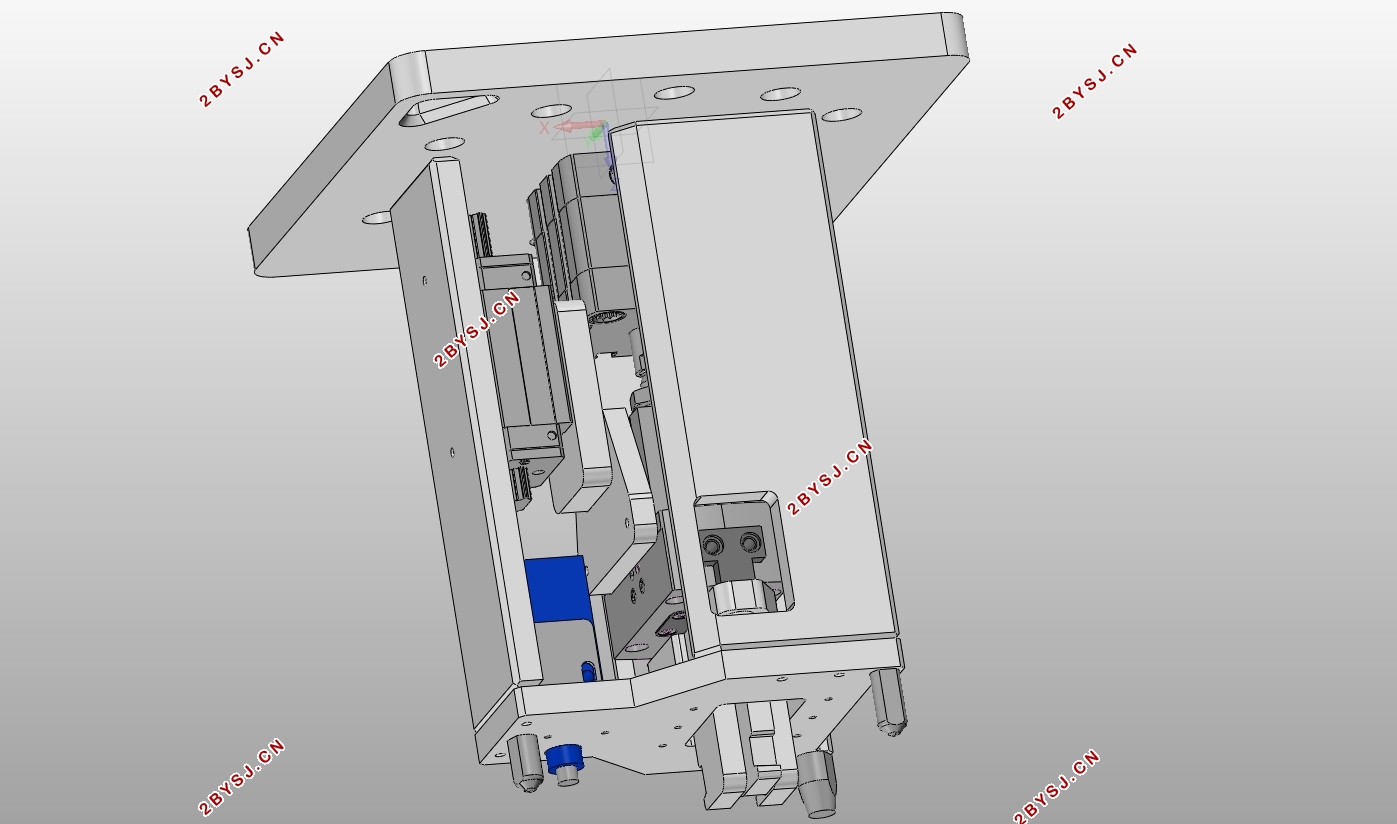

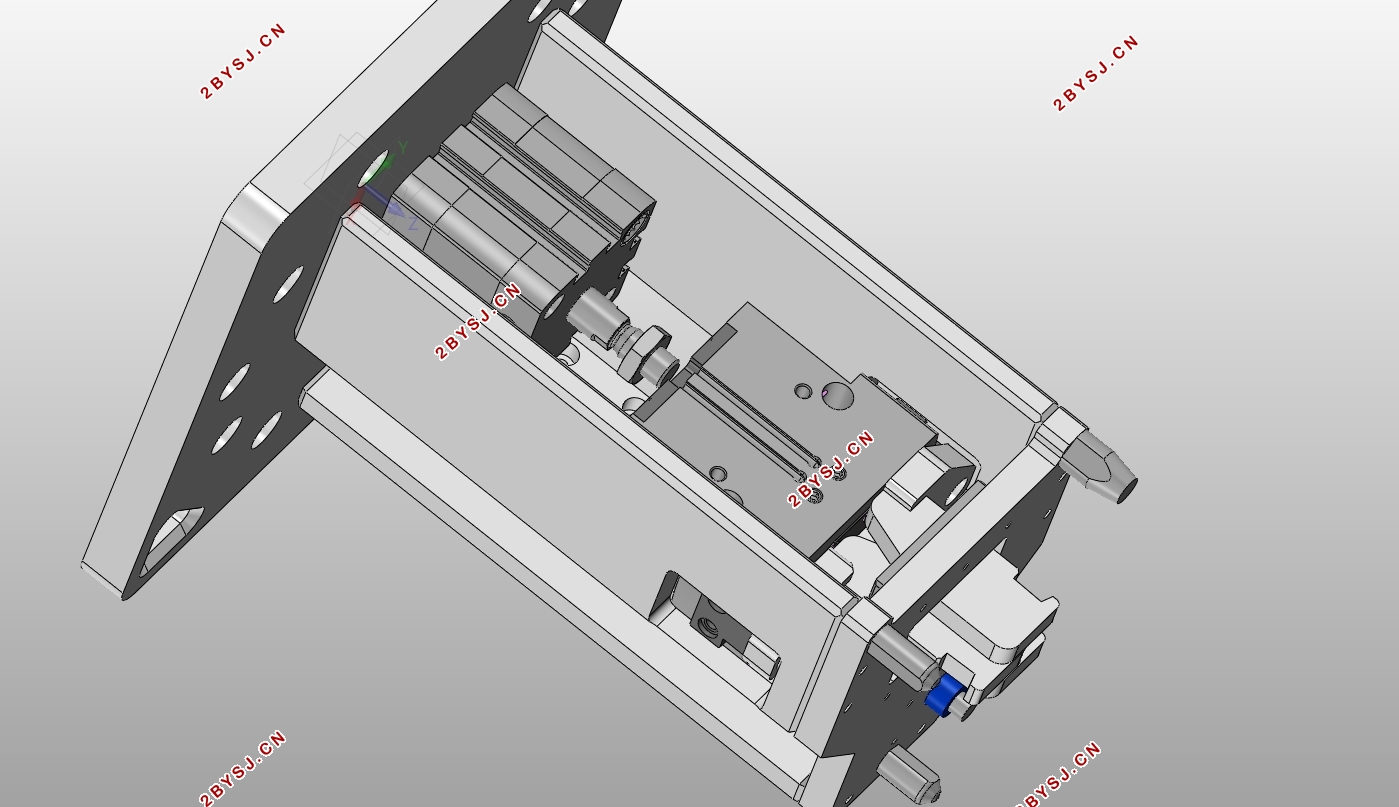

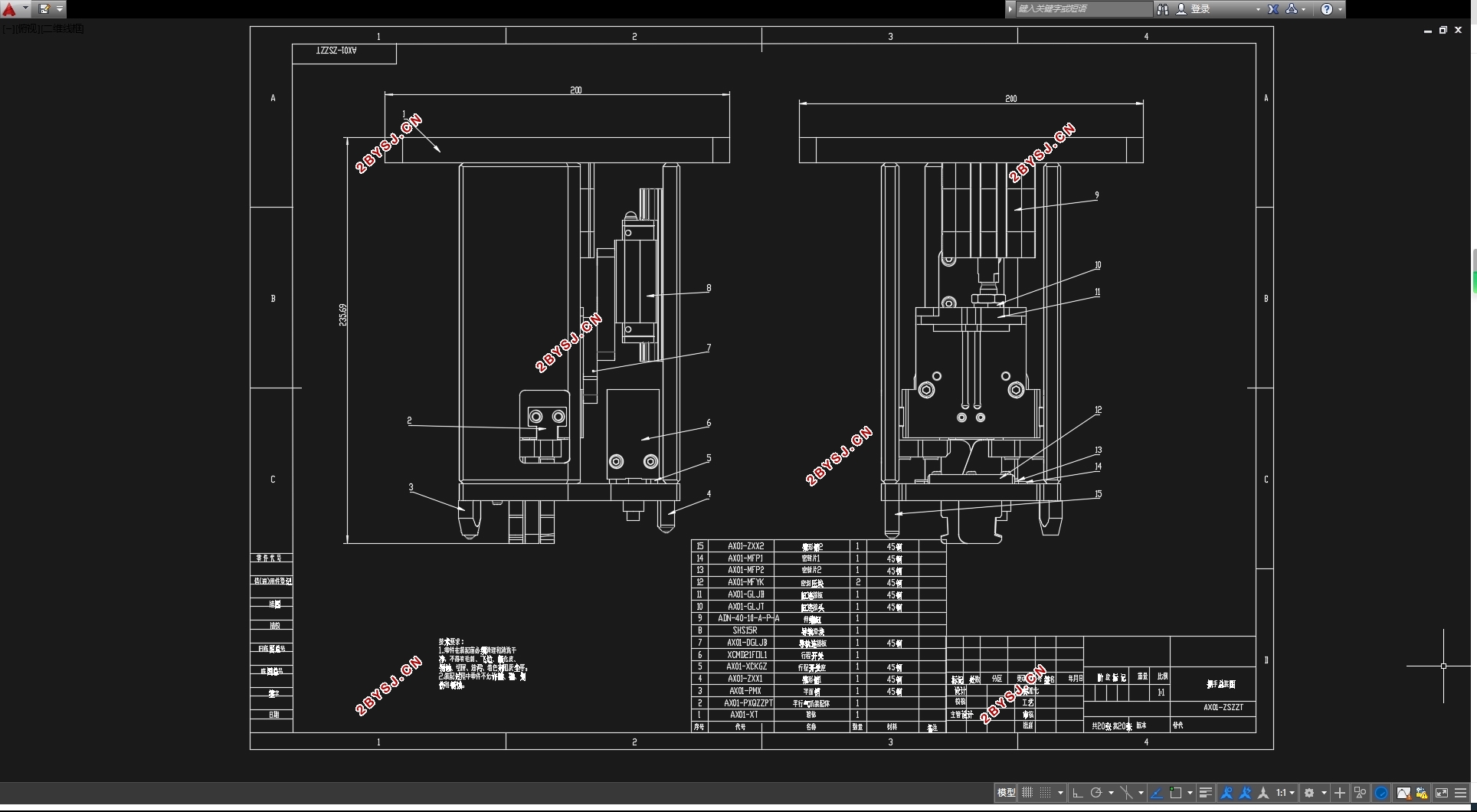

基于汽车卡钳的打磨机器人抓手设计(含CAD图,SolidWorks三维图)(任务书,开题报告,外文翻译,论文说明书14500字,CAD图20张,SolidWorks三维图)

摘 要

本次毕业设计是基于汽车刹车卡钳AX01的打磨工艺,设计一套自动夹具,安装在机器人IRB6700的法兰盘上,在机器人的控制之下,完成对卡钳AX01的抓取,左右零件的分辨并将分辨信号传送给机器人,由机器人在得到信号后选择对应的加工程序,机器人带动夹具,到达抓取位置后,机器人给夹具发出信号,使夹具完成对卡钳的自动定位与夹紧,然后机器人利用夹具夹持住卡钳往砂轮机上贴靠,完成对卡钳的飞边与浇冒口的打磨,打磨完成后机器人利用夹具夹持住打磨好的卡钳送达出料台的上方,机器人给出信号,卡钳自动放开工件。在夹具的使用过程中,夹具上的传感器要能实时反馈夹具的工作状态,判断是否发生空抓,是否发生抓取不正等问题,如果抓取发生问题,也要及时将信号传达给机器人,由机器人判断处理,以防打磨过程发生安全事故。

本次设计中查阅了大量的文献资料,了解了一些夹具设计和气动原理等知识,考虑并选定了夹紧方案,设计了气动回路,并出于安全,在气动回路中设置了掉气保护,以防在打磨过程中,由于工厂气源出现问题使得夹具对卡钳的夹持不够稳定,卡钳被砂轮打飞,造成安全事故毁坏设备。本次设计中,首先计算了切削力的大小,并根据切削力的大小,选择了用于提供夹紧力的气动元件和支撑气缸的导轨,并根据所选元件的模型,外形尺寸,设计出箱体架构和其他的连接件。

本次设计的卡钳抓手已经完成了加工、装配过程,设备现正在进行调试,并将于今年的六月底开始正式投入使用。

关键词:自动夹具;切削力计算;气动元件选型;气动回路设计;结构设计。

Abstract

The graduation design is based on the car brake calipers AX01 grinding process, the design of a set of automatic fixture, installed in the robot IRB6700 flange, under the control of the robot to complete the grasping of the caliper AX01, left and right parts of the resolution And the resolution signal is transmitted to the robot. After the robot obtains the signal, the corresponding machining program is selected, and then the robot drives the fixture. After reaching the grasping position, the robot sends a signal to the fixture to complete the automatic positioning and clamping of the caliper, The robot with a fixture, calipers, to the grinding wheel on the paste, to complete the calipers of the calipers and pouring riser, polished after the completion of the robot with a fixture and polished caliper to reach the top of the table, the robot gives the signal, The caliper can automatically release the workpiece. In the use of the fixture, the fixture on the sensor to be able to real-time feedback fixture working condition to determine whether the occurrence of empty jam, whether the occurrence of improper crawling and other issues, if the crawling problems, but also timely signal to the robot, Robot judgment processing to prevent the occurrence of safety accidents in the grinding process.

This design access to a lot of relevant information, to understand some of the fixture design and pneumatic principles and other knowledge, consider and select the clamping program, the design of the pneumatic circuit, and for security, in the pneumatic circuit set off the gas protection , In case the grinding process, due to the factory gas source problems make fixture on the calipers clamp is not stable enough, calipers were hit by a wheel, resulting in a security accident will destroy the equipment. In this design, the size of the cutting force is first calculated, and according to the size of the cutting force, the pneumatic components for supporting the clamping force and the guide rails for supporting the cylinders are selected, and according to the model, dimensions and design of the selected components Out of the box structure and other connections.

The design of the caliper hand has completed the processing, assembly process, the equipment is now in the debugging, and will begin in June this year, officially put into use.

Key words: automatic fixture; cutting force calculation; pneumatic component selection; pneumatic circuit design; structural design.

2.1卡钳打磨工艺分析

图2.1所示点画线部位为分型线位置,可见分型线布满零件的外周,且高度不一。注解11所示位置为浇冒口。本次打磨为粗加工,只需要将分型线的飞边和浇冒口全部打磨掉,所提供零件材质为铸铁,卡钳的飞边需要切削的厚度在2mm以内,卡钳的浇冒口厚度在8mm以内。本次设计拟采用机器人IRB6700通过抓手抓持卡钳,将卡钳向固定的砂轮机上贴靠以完成,砂轮机转速选取5000r/min,砂轮直径400mm,切削时机器人以100mm/s的速度运动,即切削时进给量为6m/min。工厂所提供气源气压为6bar。

目录

摘要 I

Abstract II

第1章绪论 1

第2章卡钳打磨工艺概述 3

2.1 卡钳打磨工艺分析 3

2.2 抓取方案确定 3

2.3卡钳夹持方案 5

第3章切削力计算与夹紧力确定 6

3.1 切削力计算 6

3.1.1飞边打磨的切削力计算 6

3.1.2浇冒口切削力计算 7

3.1.3切削力矩计算 7

3.2夹紧力确定…..………8

第4章气路设计与主要元件选型 10

4.1 气动回路设计 10

4.2 气缸选型 12

4.2.1 平行气爪选型 12

4.2.2伸缩缸选型 13

4.3 传感器选型 14

4.4行程开关选型 15

4.5导轨选型……………..17

第5章抓手箱体结构设计 21

5.1底板设计 23

5.2顶板设计 24

总结与展望 26

参考文献 27

致谢 28