基于螺杆连续挤出机构的巧克力3D打印机结构设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

基于螺杆连续挤出机构的巧克力3D打印机结构设计(含CAD零件图装配图)(任务书,开题报告,论文说明书22000字,CAD图纸10张)

摘要

本文主要针对传统活塞式巧克力浆体3D打印受环境温度影响较大,成型高度不理想以及3D打印连续进料的需求,根据材料特性,设计基于螺杆的固体巧克力连续进料机构,实现巧克力3D打印的进料控制,主要的研究内容如下:

(1)根据打印原料巧克力材料的基本物理特性、温度敏感性、其粘度随剪切速率变化等方面的特性,分析巧克力 3D 打印成型的原理。针对巧克力材料3D打印的工艺特性,研究保证巧克力三维成型质量的工艺条件,以确保巧克力在打印过程中可以实现连续的熔融挤出。

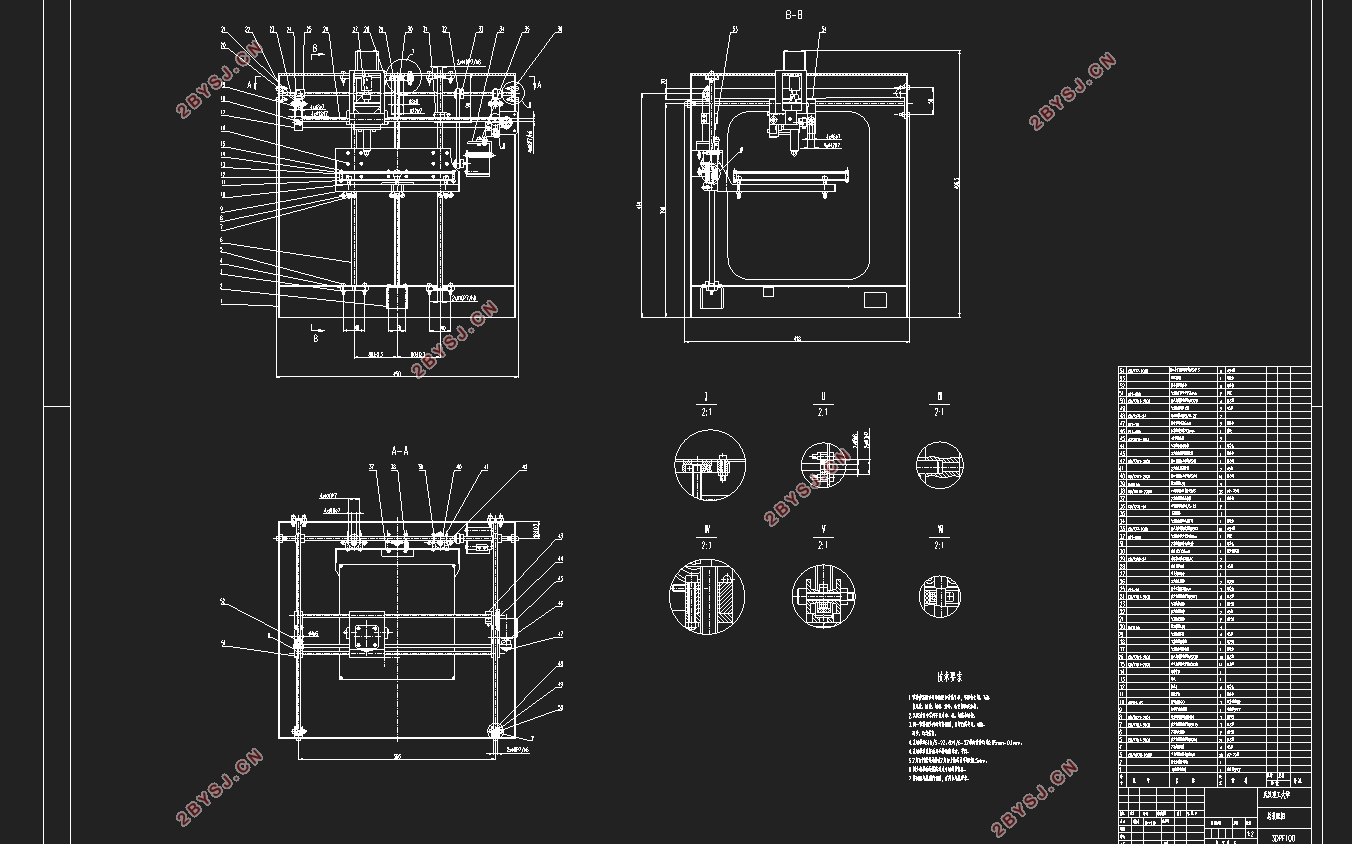

(2)在分析多种挤出机构的基础上,针对巧克力3D打印成型的工艺需求,设计巧克力3D打印机的整体结构,包括3D打印机机身,三轴运动结构以及基于螺杆的挤料机构,并对其完成三维建模,完成了巧克力3D打印机机械系统的设计。

(3)对巧克力3D打印机的主要支撑结构与移动结构进行静力学有限元分析,对连续挤出的进料螺杆机构进行温度场仿真分析,确保巧克力3D打印机的结构稳定性,以及巧克力连续挤出的可实现性。

(4)对设计的巧克力3D打印机进行调试组装,并进行巧克力连续挤料及模型打印实验,并分析打印中出现的问题,提出打印机修改与完善的方法建议。

综上,通过对巧克力3D打印工艺、成型条件的研究及巧克力3D打印机总体结构、螺杆挤料结构的设计,验证了巧克力3D打印连续挤料的可行性,得到了一种基于螺杆挤料的巧克力3D打印机设计方法,为后续巧克力3D打印机连续挤料提供了一种新的设计思路。

关键词:3D打印;巧克力3D打印机;螺杆挤出;巧克力材料

Abstract

This article mainly aims at the traditional piston chocolate paste 3D printing which is influenced by the ambient temperature, the forming height is not ideal and the 3D printing needs continuous feeding. According to the material characteristics, the solid chocolate continuous feeding mechanism based on screw is designed to achieve the feed control of the chocolate 3D printing. The main research contents are as follows:

(1) according to the characteristics of basic physical properties, temperature sensitivity and viscosity of printing raw materials, the principle of chocolate 3D printing is analyzed. In view of the technological characteristics of 3D printing of chocolate materials, the technological conditions to ensure the quality of chocolate's three dimensional molding are studied to ensure that chocolate can be continuously melted and extruded in printing process.

(2) on the basis of analyzing various extrusion mechanisms, aiming at the technological requirements of the chocolate 3D printing process, the overall structure of the 3D printer is designed, including the 3D printer fuselage, the three axis motion structure and the screw extruding mechanism, and the three-dimensional modeling is completed, and the design of the mechanical system of the chocolate 3D printer is completed.

(3) the static and finite element analysis of the main supporting structure and mobile structure of the chocolate 3D printer is carried out, and the temperature field simulation analysis of the continuous extruding feed screw mechanism is carried out to ensure the structural stability of the chocolate 3D printer and the realization of the continuous extrusion of the chocolate.

(4) debug and assemble the designed chocolate 3D printer, carry out continuous extrusion and model printing experiments on chocolate, analyze the problems in printing, and put forward methods and suggestions for printer modification and improvement.

In summary, through the study of the chocolate 3D printing process, the forming conditions, the overall structure of the chocolate 3D printer and the design of the screw extruding structure, the feasibility of continuous extrusion of 3D 3D printing is verified. A design method of the chocolate 3D printer based on screw extrusion is obtained, which provides a new design idea for continuous chocolate 3D printer continuous extrusion..

Key Words:3D printing; Chocolate 3D printer; Screw extrusion; Chocolate material

目录

摘要 I

Abstract II

第1章绪论 1

1.1 设计任务及要求 1

1.2 研究背景、目的及意义 1

1.3 巧克力3D打印技术的国内外研究现状分析 2

1.4 论文研究内容和全文组织结构 3

第2章巧克力3D打印成型原理与方法研究 5

2.1 3D打印技术基本原理 5

2.2 巧克力材料的基本特性 6

2.3 巧克力3D打印成型原理 6

2.4 巧克力3D打印成型的技术方法研究 7

2.5 本章小结 8

第3章巧克力3D打印机机械及螺杆挤出结构设计 9

3.1 引言 9

3.2 巧克力3D打印机挤出结构分析 9

3.2.1 活塞型 9

3.2.2 气压型 10

3.2.3 螺杆型 11

3.3 巧克力3D打印机总体结构 11

3.3.1 巧克力 3D打印机机身结构 12

3.3.2 XYZ三轴移动结构 13

3.3.3 XOY平面复合移动结构 14

3.3.4 Z轴移动结构 16

3.4 螺杆挤料结构设计 18

3.4.1螺杆结构设计 19

3.4.2 挤出结构设计 24

3.5 打印平台设计 24

3.6 本章小结 25

第4章巧克力3D打印机关键零部件分析 26

4.1 有限元法与分析软件 26

4.2 关键结构的静应力核验 26

4.2.1 X方向滑动结构 26

4.2.2 Y方向滑动结构 28

4.2.3 打印底板支撑板 29

4.2.4 螺杆挤出结构 31

4.3 螺杆挤料机构温度场有限元分析 34

4.4 本章小结 36

第5章巧克力3D打印机实验测试与分析 37

5.1 实验准备 37

5.2巧克力3D打印机连续挤料的实现与分析 38

5.3 本章小结 43

第6章总结与展望 44

6.1 全文总结 44

6.2 未来展望 44

参考文献 46

致谢 48