ZM800型粉体增密机设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

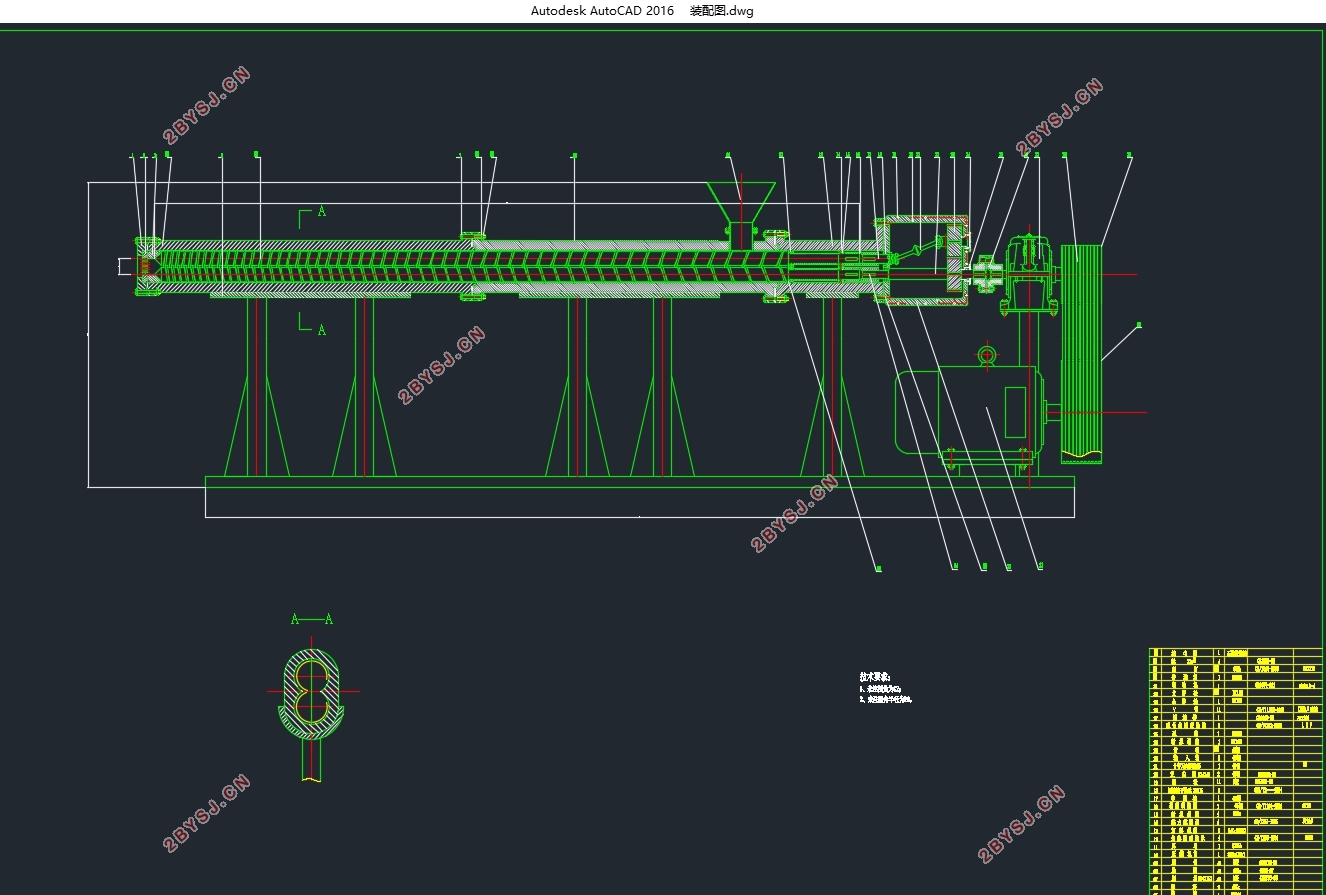

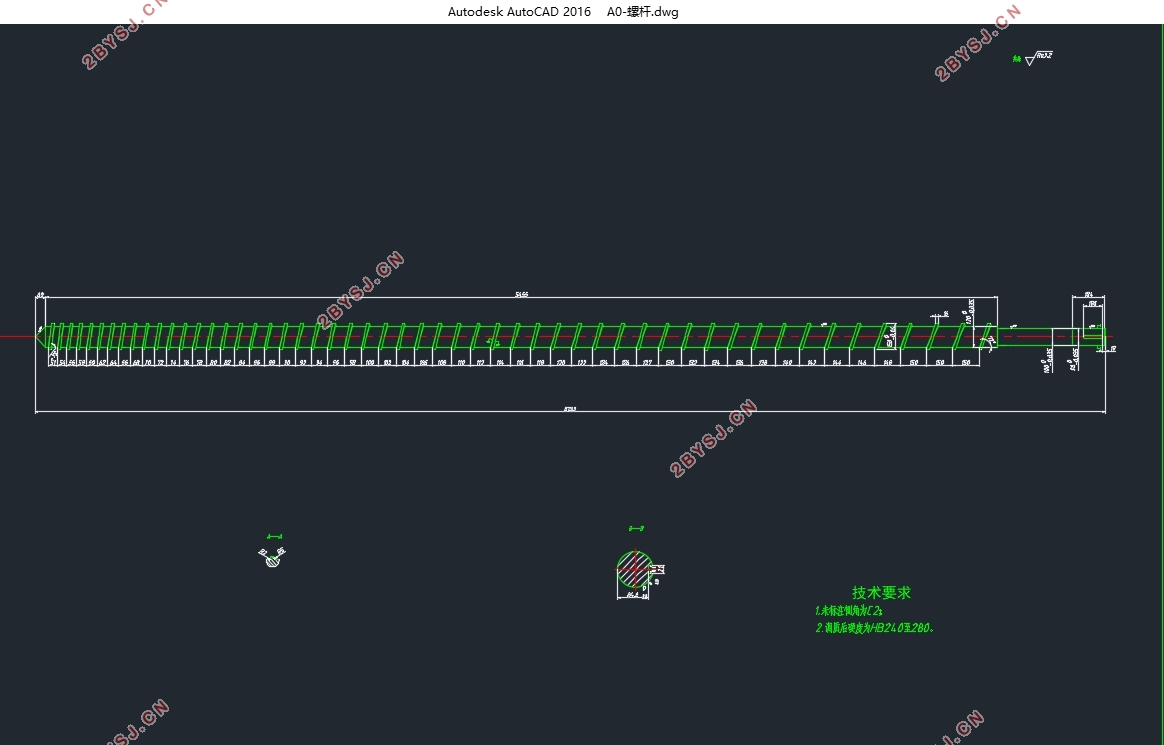

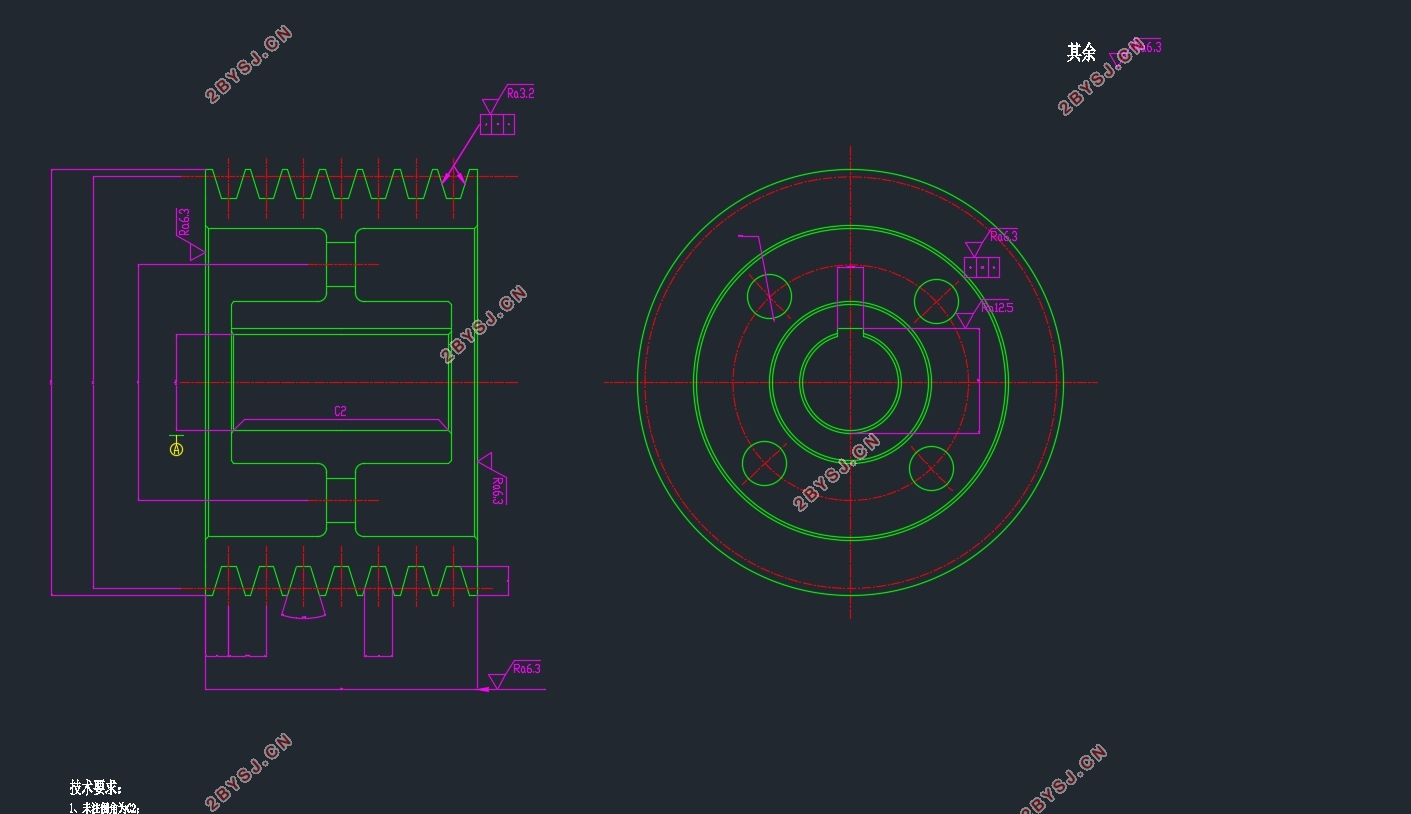

ZM800型粉体增密机设计(含CAD零件图装配图)(任务书,开题报告,外文翻译,计算说明书10000字,CAD图6张)

摘要

本次设计的课题是ZM800型粉体增密机设计。

由于轻质粉体的孔隙率较大,密度较低,不利于在生产中后续加工与运输。所以我们用粉体增密机对粉体进行增密,以减少空隙,增加其密度,并可以消除粉尘,减少环境污染,并在增加密度的同时减少粉体的结块现象,使其便于之后工序的加工,贮存,运输及使用。此增密机可以为很多轻质粉体提高经济效益,打开销路,满足用户的需要。

该增密机使用异向双螺杆结构,其具有正位移的输送作用,可产生很好的机头压力。两根反向的螺杆,由于一根的螺棱与另一根的螺槽之间有速度差,使其具有自洁作用。此外,异向双螺杆还具有物料易进啮合,生产噪音较小,环保节能等优点,被市场广泛认可。

设计中,根据产量和相关产品要求,先计算螺杆的相关参数,再选用适合的电动机,减速器,最后根据已计算参数设计传动系统相关轴,齿轮,联轴器等零件,并完成机架,料斗,机筒,模头等配套设备的设计计算,并完成装配图及重要部分零件图。

关键词:粉体物料 双螺杆挤出机 增密

Abstract

The topic of this design is the design of Type-ZM800 powder densification machine.

Due to the low density and the large porosity of the light-weight powder,we use the powder densification machine to densify the powder, So it's easy to processing, storage, transport and use.Or the powder is not conducive to the production and subsequent processing and transport.The machine also have the advantage of decreasing the caking, increasing the density, eliminating the dust,and reducing the pollution of the environment. The machine can promote the quality of various kind of the powder to improve their economic benefits.

The densification machine use the twin-screw structure that two screws rotates in reverse directions . Two screws, which has a positive displacement of conveyor,keeps the Die-head with a great pressure. Two reverse screw, due to the velocity difference of the the screw edge and the thread groove ,get the self-cleaning function. Furthermore, the machine is also easy to take material into meshing, making smaller production noise and saving energy .It also has many other advantages,so that it was widely recognized by the market.

According to the relevant requirements of the production,I calculate the screw parameters in the design first.Then choose the appropriate type of the motor and the reducer.And then according to the relevant parameters that has been calculated,design shaft, gears, couplings,hopper, barrel and the other parts of the transmission system. Finally,complete the assembly drawing and the parts drawing.

Key word:

Powder materials ,twin-screw,Densification

目录

摘要 I

Abstract II

第一章 粉体及其特性及其基本概念 1

1.1粉体的几何特性 1

1.2 粉体造粒的目的 2

1.3 粉体造粒机的常用结构 3

第二章 ZM800型粉体增密机的设计计算 5

2.1 ZM800型粉体增密机的结构 5

2. 1.1 挤压系统 5

2. 1 .2 传动系统 6

2. 1 .3 加料系统 6

2.2 ZM800型粉体增密机的主要参数 6

2.3 ZM800型粉体增密机已知条件 7

2.4 电动机的选择 7

2.5减速器的选择 8

2.6带传动的设计 10

2.7螺杆设计 10

2.8螺纹部分的几何形状的选择 12

2.9 传动轴的设计 12

2.10 齿轮的设计 13

2.11 料斗的设计 14

2.12 轴承的设计 15

2.13 轴承的校核 16

2.14 输入轴的校核 18

2.15螺秆的强度校核 20

结束语 22

参考文献 23

致谢 25