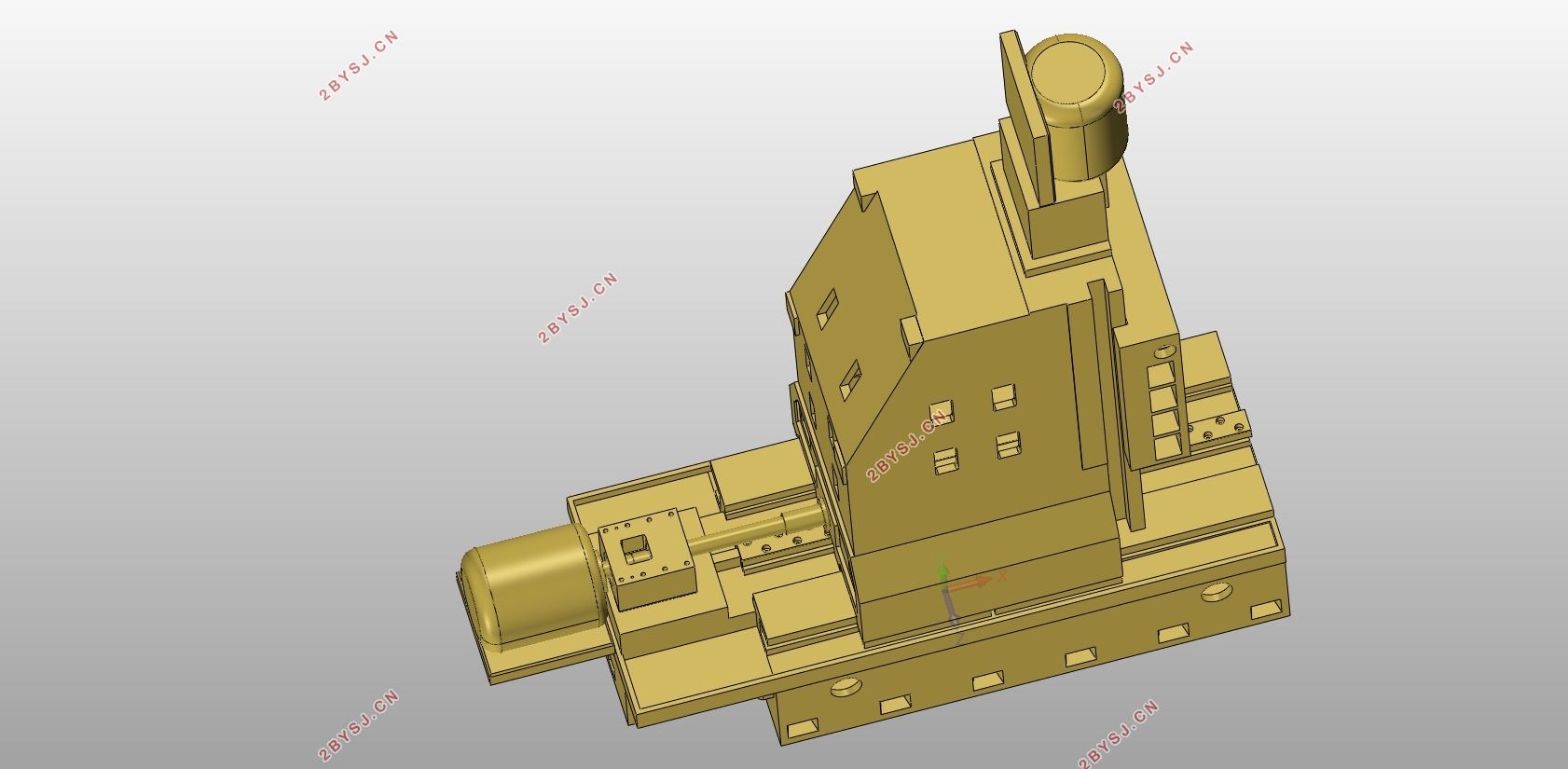

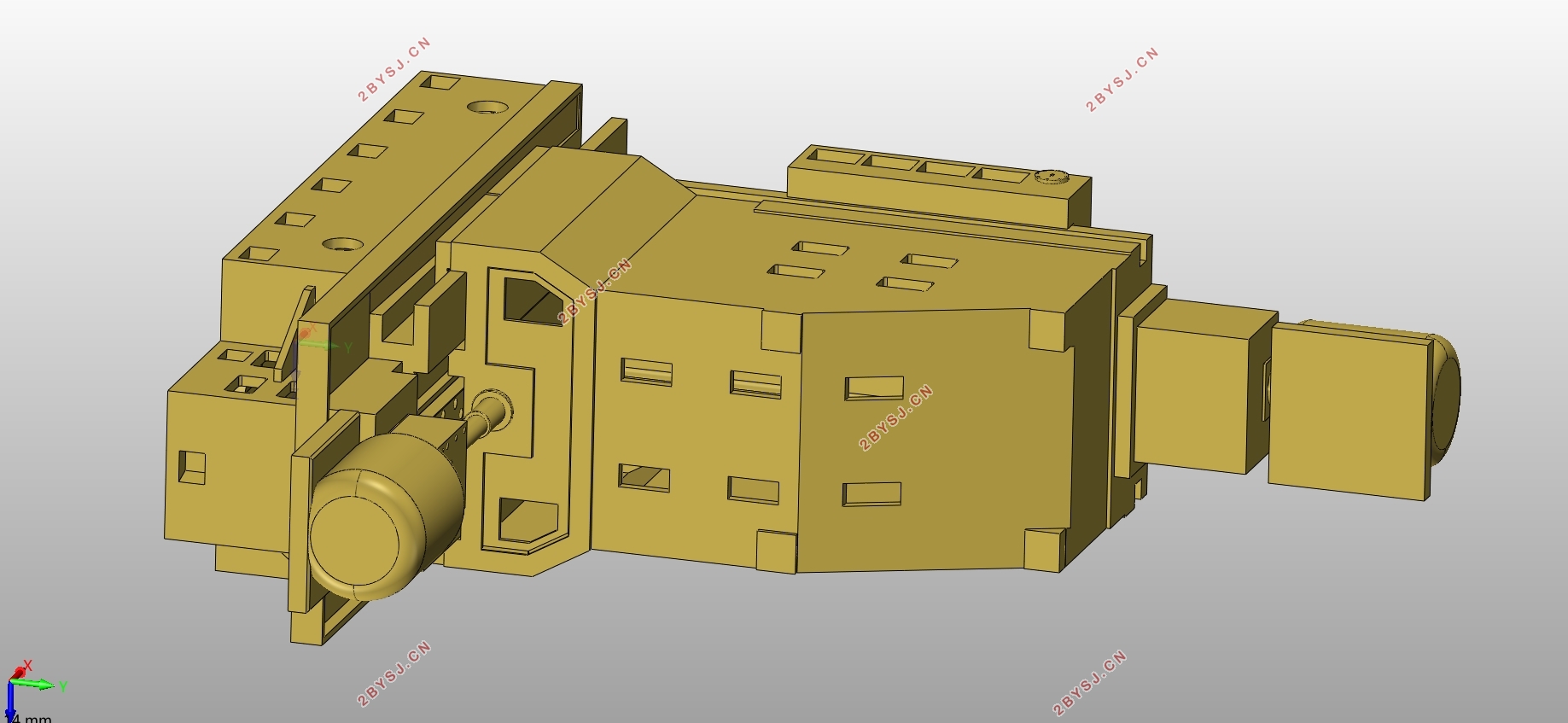

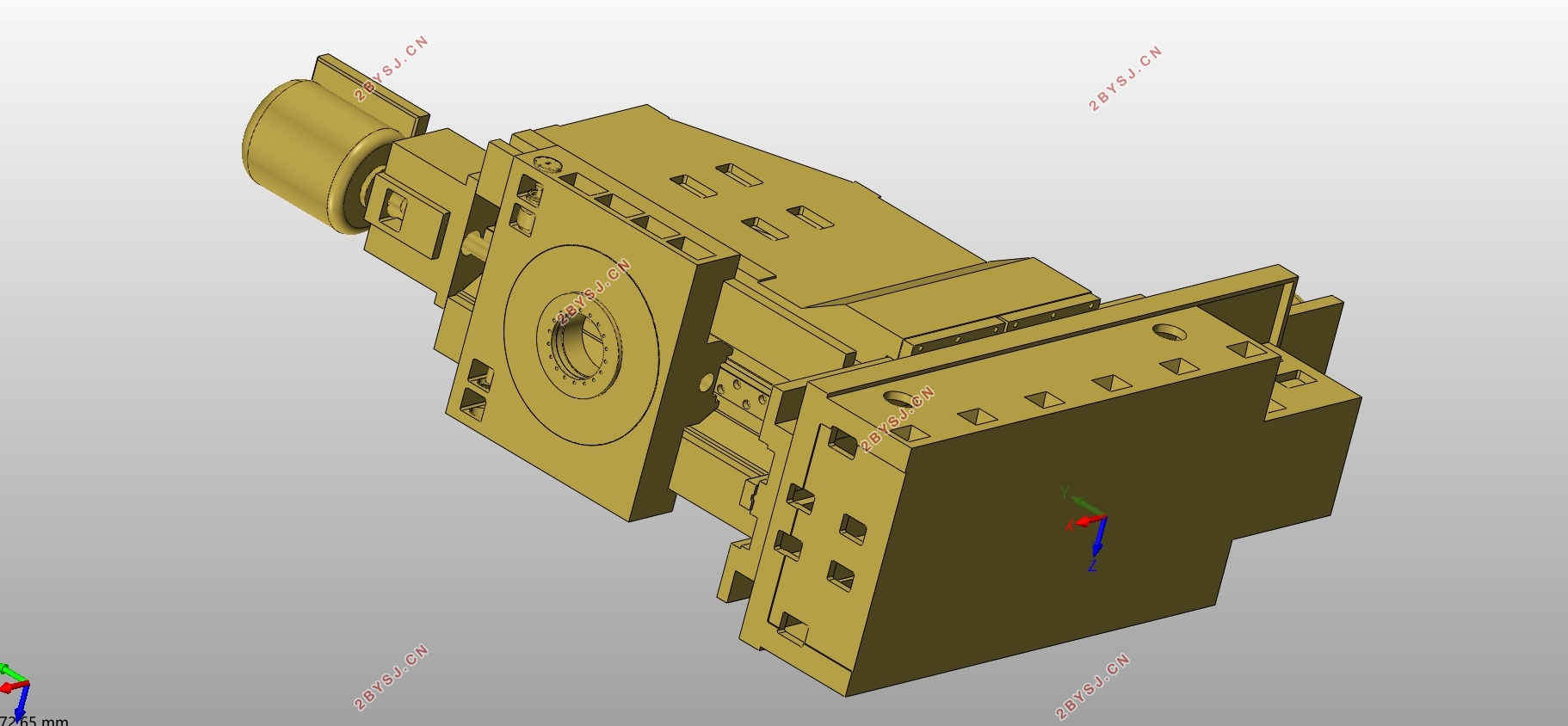

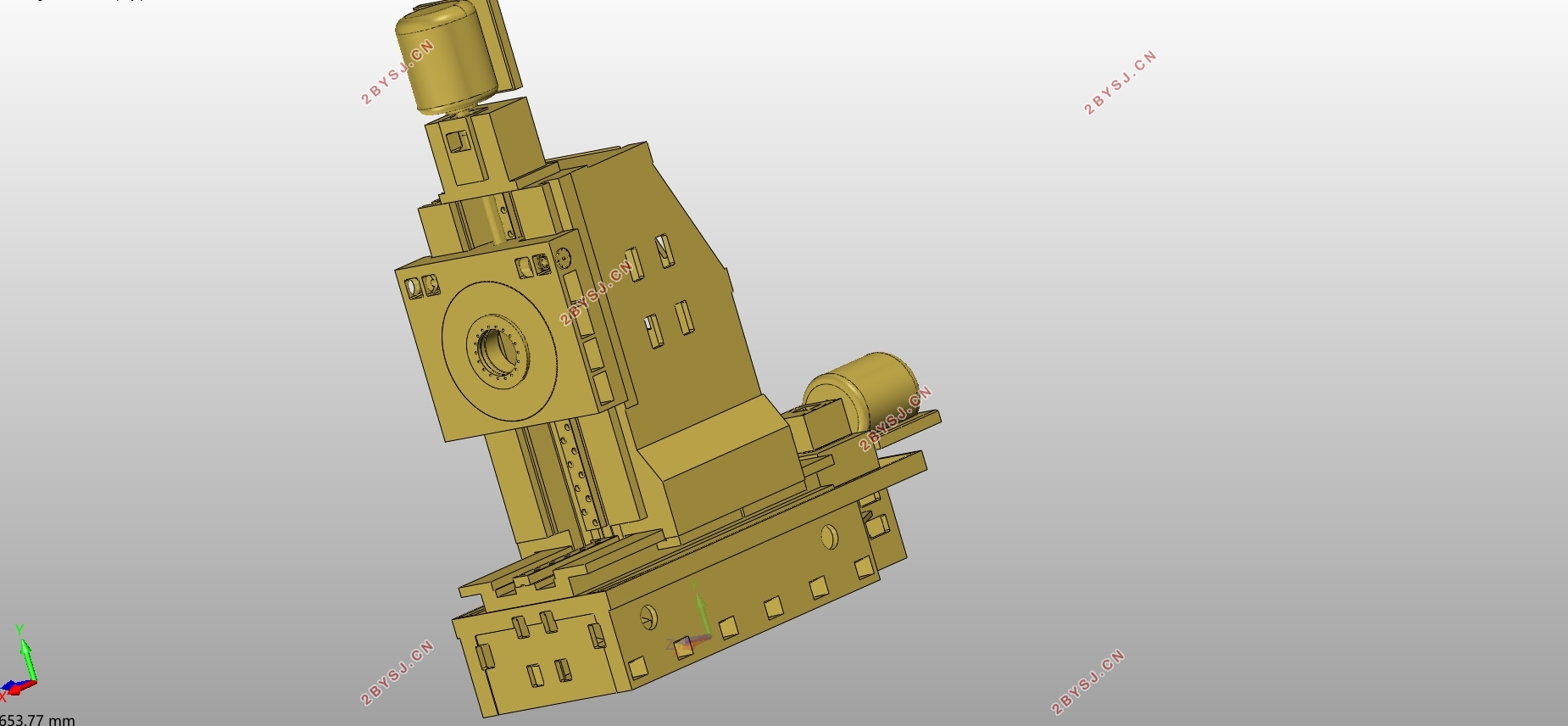

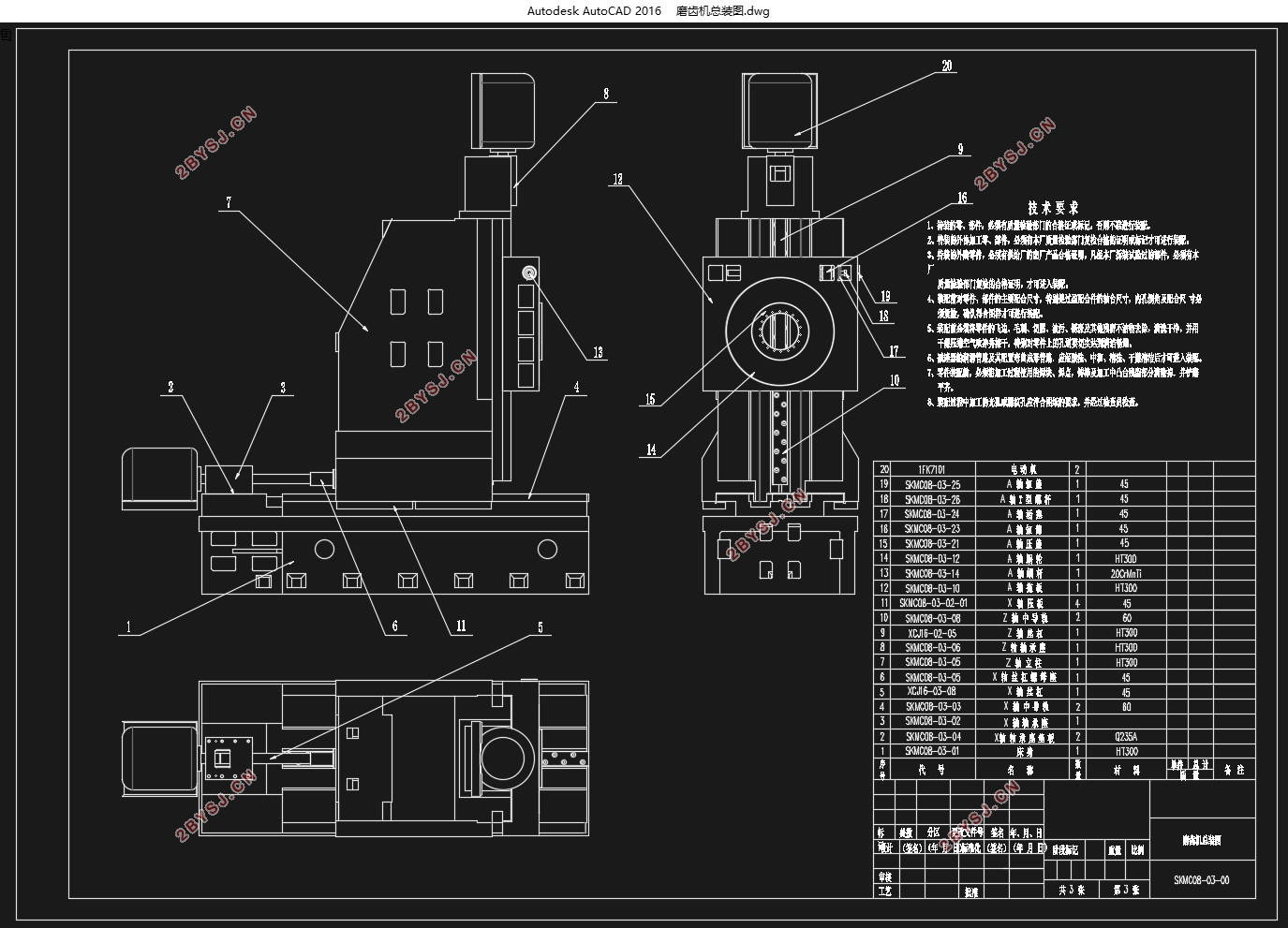

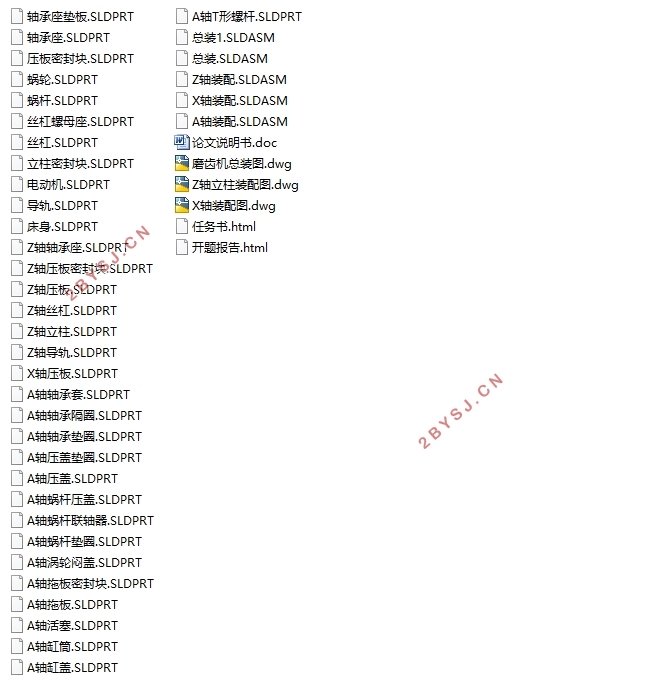

齿轮加工机床模块化设计(磨齿机)(含CAD装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

齿轮加工机床模块化设计(磨齿机)(含CAD装配图,SolidWorks三维图)(任务书,开题报告,论文说明书22000字,CAD图纸3张,SolidWorks三维图)

摘 要

用户需求的个性化和多样化正成为机床制造业发展的一个重要特色,如何快速响应市场的需求对企业在竞争中占据有利地位具有重要的意义。本文针对这一企业需求,将模块化设计思想引入了磨齿机机床的设计当中,在研究模块化设计的一般方法的基础上针对磨齿机机床机床的特点对其进行了模块的划分、建模、参数化设计等工作,并基于SolidWorks进行了磨齿机机床参数化设计。主要研究内容如下:

文章首先研究并总结了模块化设计原理及其核心思想,并在此基础上提出了针对磨齿机机床的具体的模块划分方法;在对磨齿机机床进行模块划分后,从中挑选出几个重要的零件模块进行参数化设计工作。通过SolidWorks将磨齿机所有的零部件组装起来,完成磨齿机整体框架的总装。

关键词:模块化设计 磨齿机机床 模块划分 参数化设计

Modular Design of Gear Machining Machine Tool

Abstract

The personalization and diversification of user's needs are becoming an important feature of the development of machine tool manufacturing industry.How to respond quickly to the demand of the market has important significance for the enterprise to occupy the advantageous position in the competition.In this paper, according to the needs of the enterprise, the modular design idea is introduced into the grinding tooth machine design, in the general method of modular design based on for milling gear machine tool machine characteristics of the module partition, modeling, parametric design work and based on SolidWorks were grinding machine parametric design.The main research contents are as follows:

In this paper, the design principle and the core idea of the modular design are summarized, and the method of dividing the grinding machine tool is put forward.After the division of the machine tool, some important parts of the machine tool are selected from the design of the parameters.Through the SolidWorks, all parts of the grinding machine are assembled, and the assembly of the whole frame of the grinding machine is finished.

Key Word: Modular design;Grinding machine tool;Module partition;Parametric design

目 录

摘要.............................................................I

ABSTRACT........................................................II

第一章 绪论......................................................1

1.1课题研究背景和意义..................................................1

1.1.1课题研究的背景.................................................1

1.1.2课题研究的意义.................................................1

1.2磨齿方法概述........................................................2

1.3磨齿机发展现状和趋势................................................4

1.3.1国外磨齿机发展现状.............................................4

1.3.2国内磨齿机发展现状.............................................6

1.3.3磨齿机发展趋势.................................................7

1.4本文的主要研究内容..................................................8

第二章 磨齿机模块化设计方法.....................................10

2.1模块的设计的理论基础...............................................10

2.1.1模块化设计的相应概念..........................................10

2.1.2模块化设计的方式和一般过程....................................10

2.2模块的划分.........................................................13

2.2.1模块划分的原则................................................13

2.2.2模块划分的角度................................................14

2.2.3模块的聚类方法................................................17

2.3本文对磨齿机采取的划分方法.........................................22

第三章 磨齿机模块几何建模技术研究...............................25

3.1磨齿机元件几何建模常用方法.........................................25

3.2磨齿机零件的几何建模...............................................29

3.3磨齿机组件的几何建模...............................................33

第四章 SolidWorks磨齿机三维图的设计.............................40

4.1SoildWorks软件简介.................................................40

4.2对磨齿机零件模块的参数化设计.......................................40

4.3对磨齿机模块的参数化设计以及磨齿机总装图...........................43

第五章 总结与展望...............................................47

5.1全文总结...........................................................47

5.2课题展望...........................................................47

参考文献........................................................48

致谢............................................................51