液压往复密封件耐久性试验设计(含CAXA图)

无需注册登录,支付后按照提示操作即可获取该资料.

液压往复密封件耐久性试验设计(含CAXA图)(任务书,开题报告,论文说明书14000字,CAXA图2张)

中文摘要

液压往复密封件的性能对液压系统的安全及平稳运行具有重要意义,液压往复密封件的耐久性试验检测方式一直是行业内关注的重点,但对耐久性的检测仍未确立出一个明确的标准。

针对这一问题,本次论文重点对测试液压往复密封件耐久性的实验装置进行设计,使用AMEsim液压仿真软件进行仿真模拟,并验证结果是否与实验要求条件相符合,进一步探索耐久性实验的功率回收问题。本次论文取得了如下成果:

(1)分析测试液压往复密封件耐久性的国家标准(GB 32217-2015),梳理实验整体设计思路与基本实验要求,为后续实验装置的设计与仿真模型的搭建提供重要依据。

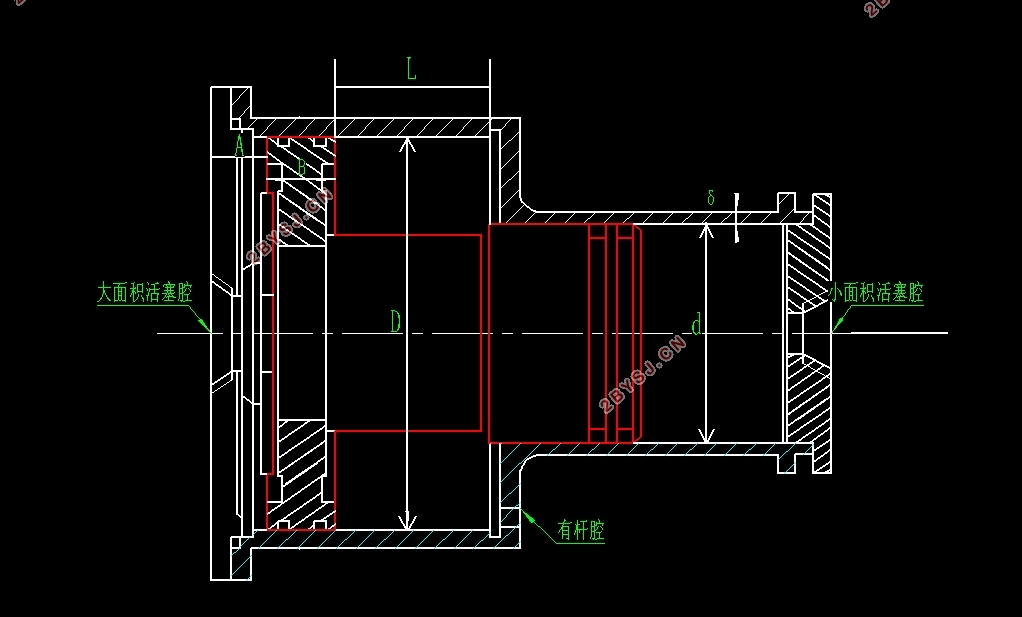

(2)设计实验原理图,要求能够实现压力加载单元、速度控制单元、温度控制单元三部分试验条件;依据实验设计要求,设计满足实验装置方案,为仿真搭建完成基础设计。

(3)使用AMEsim 液压仿真软件,搭建仿真模型图;计算并设置参数,并不断调试,使得仿真模型能够正常运行。对仿真结果进行后处理,验证仿真结果是否满足要求。

(4)考虑系统的功率回收设计。采用马达-泵的液压回路进行功率回收,节约能源;分析调压装置的结构设计,计算调压装置的主要尺寸。

关键词:液压往复密封,耐久性测试,AMEsim仿真软件,功率回收

Abstract

The performance of hydraulic reciprocating seals is important for the safety andperformance of hydraulic systems. The durability test of hydraulic reciprocating seals has always been the focus in the industry, but the standard test of durability has not yet beagreed.

From the above problem, the paper focuses on the design of the devices for testing the durability of hydraulic reciprocating seals, and AMEsim has been applied to simulate and monitor if the results are consistent with the conditions the test requried. The paper further explores Power recovery for the durability test .Main results are as follows:

(1) the national standard test of hydraulic reciprocating seal durability has been analyzed, to provide an important basis for the next steps.

(2) Based on the principle of choosing equipments, the devices for the test has been studied.The equipments are individed as three parts, including conditions of the pressure loading unit, the speed control unit and the temperature control unit. Then design scheme to meet the experimental requirements is designed .

(3) AMEsim has been applied to build simulation model; The reseachers calculate the parameters of model and continue to debug to make the simulation model operate normaly. Thepostprocessed date be used to verify whether the results of simulation reach the conditons the test required.

(4)The motor - pump hydraulic circuit has been considered to be applied in the test for optimization.

Keywords: hydraulic reciprocating seal, durability test, AMEsim , power recovery

目 录

中文摘要 I

Abstract II

第1章 绪论 1

1.1研究的背景及意义 1

1.2液压往复密封件国内外研究综述 1

1.3液压往复密封件国家标准试验原理 3

1.4论文研究内容及结构安排 5

第 2章 液压往复密封件耐久性试验设计 6

2.1耐久性试验的设计思路 6

2.1.1压力加载单元的设计 7

2.1.2速度控制单元的设计 7

2.1.3温度控制单元的设计 8

2.2本章小结 9

第3章 基于AMEsim的液压仿真 10

3.1使用AMEsim搭建总体仿真图 10

3.1.1压力加载单元的模型搭建 10

3.1.2速度控制单元的模型搭建 11

3.1.3温度控制单元的模型搭建 12

3.2液压模型参数的选用与计算 12

3.3 AMEsim仿真结果的验证 14

3.4本章小结 16

第4章 功率回收设计与调压装置校核 17

4.1功率回收方案的设计 17

4.1.1功率回收方案的选用 17

4.1.2功率回收的效率分析 18

4.2调压装置的主要尺寸计算 18

4.3本章小结 21

第5 章 总结与展望 22

5.1论文研究总结 22

5.2有待研究的问题 22

致谢 24

参考文献 25