门座起重机刚性四连杆金属结构失效修复设计及设备管理对策与分析(象鼻梁)(

无需注册登录,支付后按照提示操作即可获取该资料.

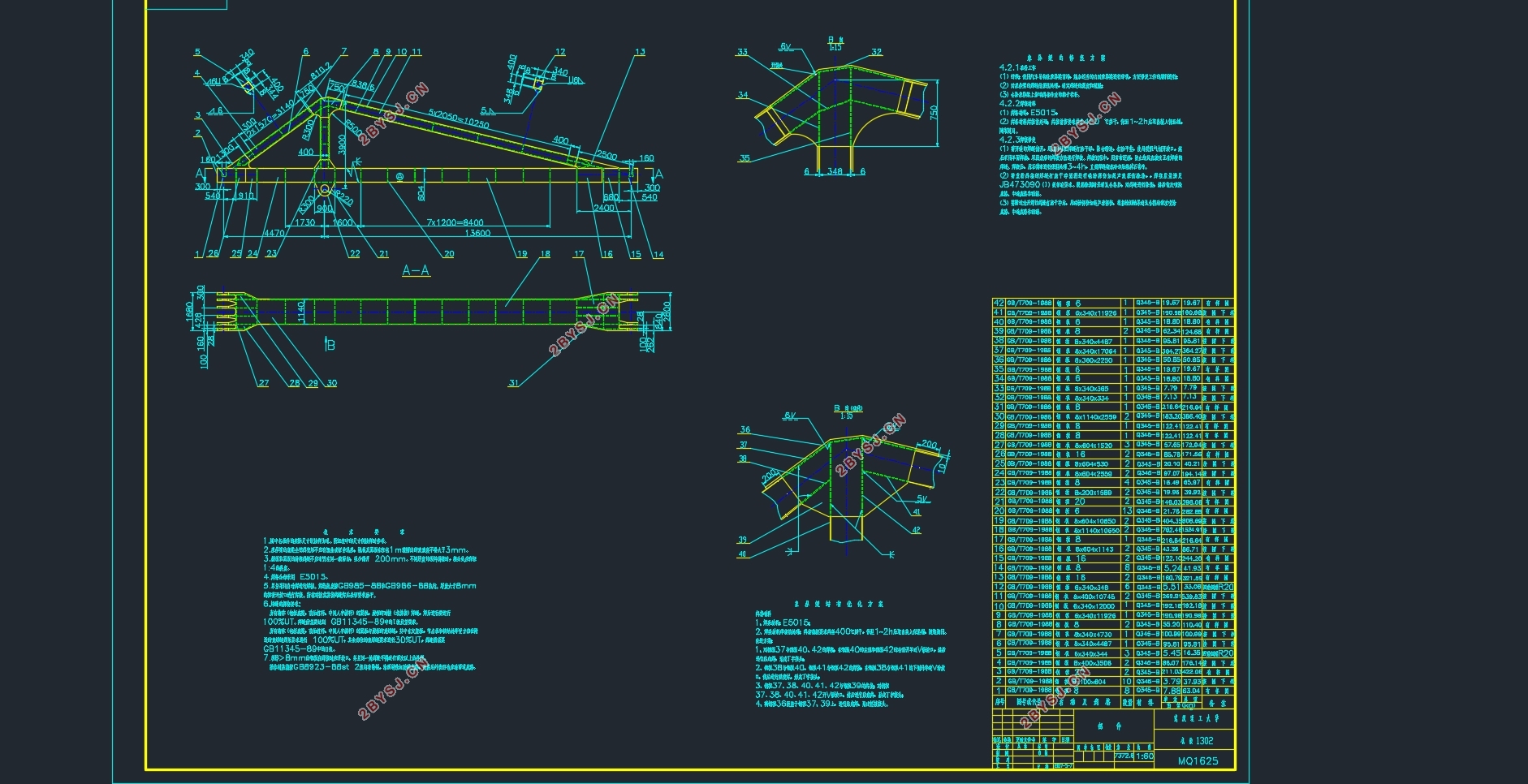

门座起重机刚性四连杆金属结构失效修复设计及设备管理对策与分析(象鼻梁)(含CAD图)(任务书,开题报告,论文说明书13000字,CAD图1张)

摘要

门座起重机具有功能强大、生产效率高、可靠安全等特点,是港口重要的装卸设备,而其象鼻梁结构在门座起重机的运行中发挥着非常重要的作用。在门机中,象鼻梁这一结构是处于最前、最上位置的结构,这个结构的质量的好坏对于整个起重机的运行的安全性、稳定性有着直接的关系。当象鼻梁结构发生变形、断裂等故障时,起重机就会被迫停止工作,影响整个工程的进度。所以,讨论门座起重机的象鼻梁变形的原因,并制定相应的解决对策,在确保象鼻梁的安全、稳定方面具有非常重要的意义。

利用力学分析的方法设计钢结构,这是在传统的金属结构设计中经常使用的一种手段,但是由于理论上的力学分析具有一定的局限性,在进行金属结构的计算和分析过程中,可以确定该钢结构截面的尺寸,从而确定钢结构的设计制造所需要的型钢的规格以及相对应的板厚等相关数据,但是这种方法只能够进行总体的计算。然而对于钢结构的某些细节部分却不能精确地计算,这将会导致一些问题的出现,比如在钢结构的整体强度上,一部分的钢结构能够满足强度要求,但是在部分结构的一些细节地方,将可能产生经常出现又容易忽略的一些安全隐患,比如发生开裂等现象。随着社会的迅速发展,计算机技术以一种日新月异的速度迅猛地发展着,学校特别是企业越来越离不开计算机,而这又促进了计算机技术的发展,计算机软件几乎是以日更的速度进行着更新换代。在机械工程方面,有限元相关软件技术的使用与改进在很大的程度上解决了运用传统的力学分析的方法设计钢结构而出现的不能对细节部分进行计算分析的缺陷。在进行钢结构的设计过程中,建立有限元模型,对实际的情况进行模拟,那么通过计算就能得到整个结构的应力分布或变形,从而可以据此对该结构进行针对性地改进设计。

通过对象鼻梁进行受力分析、失效分析,提出了相关的改进措施,然后结合实例做出相应的修复方案,又针对案例设计了优化后的结构。

优化后的结构中焊缝较长,将力进行了分散,因此结构受到的应力影响将会减小很多。

关键词:门座起重机;象鼻梁;开裂;修复;优化

Abstract

The portal crane is characterized by its powerful, high production efficiency, reliable and safe, and it is an important loading and unloading equipment in the harbor, and its elephant bridge structure plays a very important role in the operation of portal crane. In the door machine, the structure of the bridge of the nose is in the foremost, the top position of the structure, the quality of the structure of the crane for the operation of the safety and stability of a direct relationship. When the nose bridge structure deformation, fracture and other failures, the crane will be forced to stop working, affecting the progress of the entire project. Therefore, it is of great significance to ensure the stability and stability of the bridgehead bridge. Therefore, it is of great significance to ensure the safety and stability of the bridgehead bridge.

It is a kind of means which is often used in the design of traditional metal structure by means of mechanics analysis. However, due to the limitation of theoretical mechanics analysis, it can be used in the calculation and analysis of metal structure. Determine the size of the steel structure cross-section, so as to determine the steel design and manufacture of steel specifications and the corresponding thickness and other related data, but this method can only be the overall calculation. However, some of the details of the steel structure can not be accurately calculated, which will lead to the emergence of some problems, such as the overall strength of the steel structure, a part of the steel structure to meet the strength requirements, but some of the details of some of the structure , Will likely produce frequent and easy to overlook some of the security risks, such as the occurrence of cracking and so on. With the rapid development of society, computer technology to a rapid pace of development, the school, especially enterprises are increasingly inseparable from the computer, which in turn promote the development of computer technology, computer software is almost more The speed of the replacement. In the mechanical engineering, the use and improvement of finite element related software technology to a large extent to solve the use of traditional mechanical analysis of the design of steel structure and the details of the part can not be calculated and analyzed defects. In the process of steel structure design, the finite element model is established, and the actual situation is simulated. Then, the stress distribution or deformation of the whole structure can be obtained by calculation, so that the structure can be improved accordingly.

Through the analysis and failure analysis of the nose of the object, the relevant

improvement measures are put forward, then the corresponding repair scheme is made with the example, and the optimized structure is designed for the case.

After the optimized structure, the weld is long and the force is dispersed, so the stress affected by the structure will be reduced much.

Keywords: door crane;elephant trunk;cracked;repair; optimization

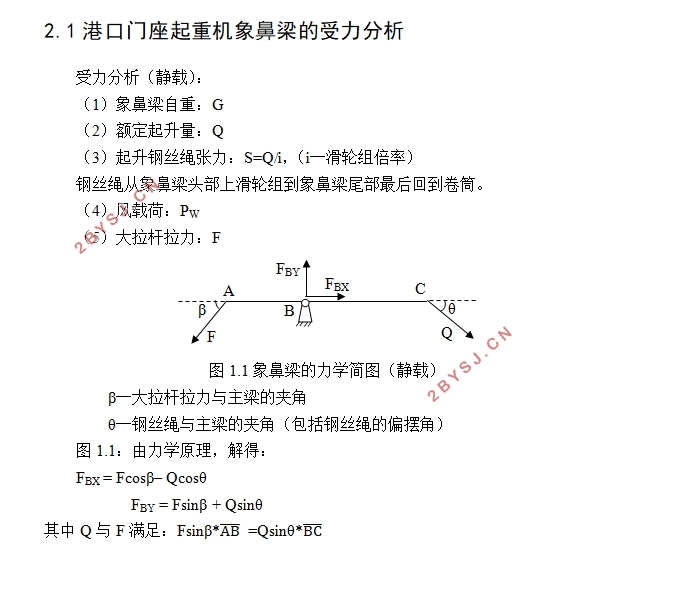

港口门座起重机象鼻梁的受力分析

受力分析(静载):

(1)象鼻梁自重:G

(2)额定起升量:Q

(3)起升钢丝绳张力:S=Q/i,(i─滑轮组倍率)

钢丝绳从象鼻梁头部上滑轮组到象鼻梁尾部最后回到卷筒。

(4)风载荷:PW

(5)大拉杆拉力:F

目录

摘要 1

Abstract 2

第1章绪论 5

1.1 研究背景 5

1.2 国内外研究现状 5

1.3研究目的及意义 6

第2章港口门座起重机象鼻梁的受力分析 8

2.1港口门座起重机象鼻梁的受力分析 8

第3章港口门座起重机象鼻梁的失效分析 9

3.1港口门座起重机象鼻梁的结构分析 9

3.2港口门座起重机象鼻梁的失效原因 9

3.3港口门座起重机象鼻梁的改进措施 10

3.3.1规范操作流程、严禁超载现象 10

3.3.2提高象鼻梁结构的局部稳定性 10

3.3.3做好日常的检修、维护工作 10

3.3.4确保象鼻梁结构设计的合理性 11

第4章港口门座起重机象鼻梁的优化 12

4.1港口门座起重机象鼻梁的开裂实例 12

4.2港口门座起重机象鼻梁的修复方法 13

4.2.1准备工作 13

4.2.2焊接材料 13

4.2.3焊接修复 13

4.3港口门座起重机象鼻梁的优化方法 14

4.3.1焊接材料 14

4.3.2优化方法 14

第5章港口门座起重机象鼻梁的设备管理对策 15

5.1设备管理概述 15

5.2从技术方面预防与控制象鼻梁结构故障 15

5.3从管理方面预防与控制象鼻梁结构故障 16

第6章环境影响及经济性分析 18

6.1环境影响分析 18

6.2经济性分析 19

第7章总结与展望 21

7.1全文总结 21

7.2展望 21

致谢 23

参考文献 24