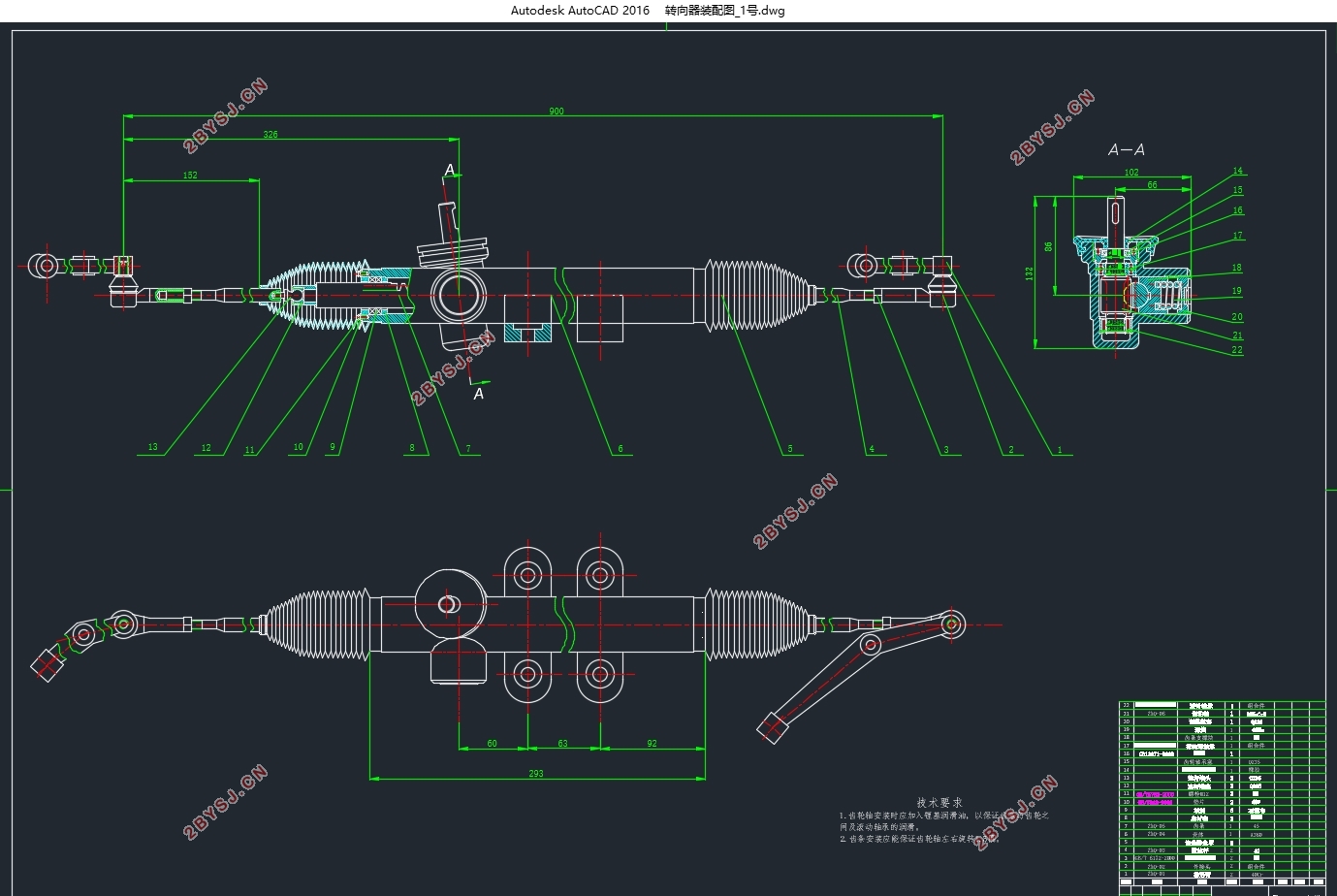

变传动比齿轮齿条转向器(含CAD零件图装配图)(英文版)

无需注册登录,支付后按照提示操作即可获取该资料.

变传动比齿轮齿条转向器(含CAD零件图装配图)(英文版)(任务书,开题报告,文献摘要,外文翻译,论文说明书英文版12000字,CAD图纸5张)

Abstract

This graduation design mainly carries on the design variable transmission gear rack steering gear. First, the size of steering trapezoid was calculated and checked. Understand the structural characteristics, layout forms and dynamic output forms of different types of steering gear. After comparison, determine the overall structure scheme and layout forms.According to the trapezoidal arm checking result and the variable transmission ratio curve, the dimension parameters of the rack and pinion are calculated and calculated, including the selection of the gear rack material, the force analysis, and the strength check. For the structural dimensions that are not designed in the steering system, the reference structure is used to design the structure; the assembly dimension chain is established on the gear shaft, precision design, modeling and finite element analysis of the gear shaft are performed; Three-dimensional modeling, and finally draw two-dimensional engineering drawings.

Key words: steering gear, variable transmission ratio, design calculation, strength check

Catalogue

Abstract 1

1.Introduction to steering system and rack and pinion steering gear 1

1.1 Foreword and the purpose and significance of the topic selection 1

1.2 Development status at home and abroad 2

1.3 Introduction to steering system and rack and pinion steering gear 3

1.3.1 Steering system overview 3

1.3.2 Classification of rack and pinion steering gears 5

1.3.3 Advantages of Variable Transmission Ratio Rack and Pinion Steering Gear 8

2、Variable transmission ratio rack and pinion steering gear principle 8

2.1 Transmission ratio introduction and change characteristics 8

2.2 Transmission principle of gear rack commutator with variable transmission ratio 11

2.3 Gear parameter design and installation of staggered angles 14

3.Three-dimensional modeling method for gears and racks 17

3.1 Study on Mathematical Modeling Method of Rack Face of Variable Transmission Ratio 17

3.2 Two methods of comparative analysis 24

4、Steering gear rack design calculation process 25

4.1 Selected models and parameters 25

4.2 Preliminary determination of the size of steering trapezoidal mechanism 27

4.2.1 Steering gear in-situ steering resistance torque calculation 28

4.2.2 Calculation of average angular transmission ratio of steering gear 29

4.2.3 Maximum force on the steering wheel Fh 29

4.2.4 The maximum torque acting on the steering wheel 30

4.2.5 Turn to maximum resistance Fw 30

4.2.6 Average transmission ratio of steering gear ip 30

4.3 Design of rack and pinion steering gear 30

4.3.1 Design requirements of gear rack type steering gear and design ideas of variable transmission ratio gear rack 31

4.3.2 The parameters of the gear and the rack of ab segment are selected 32

4.3.3 Calculation of the Size of Gear Rack 35

5、Gear strength check 38

5. 1 Check the contact fatigue strength of gears with minimum transmission ratio 38

5.2 Calculation of tooth root bending fatigue strength 40

5.3 Gear shaft accuracy design 41

5.3.1 Gear shaft structure 41

5.3.2 Precision design 42

5.3.3 Gear shaft with dimension chain 43

5.4 Gear shaft strength check 47

Force analysis of gear shaft 47

5.5 Analyze the results 52

5.5.1 Check the property sheet of ANSYS material to get the property of 40Cr and establish the 40Cr material library 53

5.5.2 Import the pinion shaft, select 40Cr material, and mesh 53

5.5.3 Apply a constraint to the shaft and apply a load 54

6、Design of clearance adjustment spring 56

6.1 Selection of clearance adjustment spring material 56

6.2 Initial adjustment and calculation of clearance adjustment spring wire diameter 56

6.3 Calculation of the effective number of laps and free height of the clearance adjustment spring 58

6.4 Clearance adjustment spring other structural parameters calculation. 59

6.5 Clearance adjustment spring checking 60

6.5.1 Clearance adjustment spring stability check 60

6.5.2 Checking fatigue adjustment of clearance adjustment spring 60

6.5.3 Clearance spring adjustment spring static strength check 61

6.6 Parameters of the spring 61

7.other parts of the selection and lubrication method to determine 63

7.1 Selection of Bearings 63

7.2 Selection of Lubrication Methods and Lubricants 65

Conclusion 66

References 67

THANKS 68