物流液压升降台设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

物流液压升降台设计(含CAD图)(论文说明书10000字,CAD图8张)

摘 要

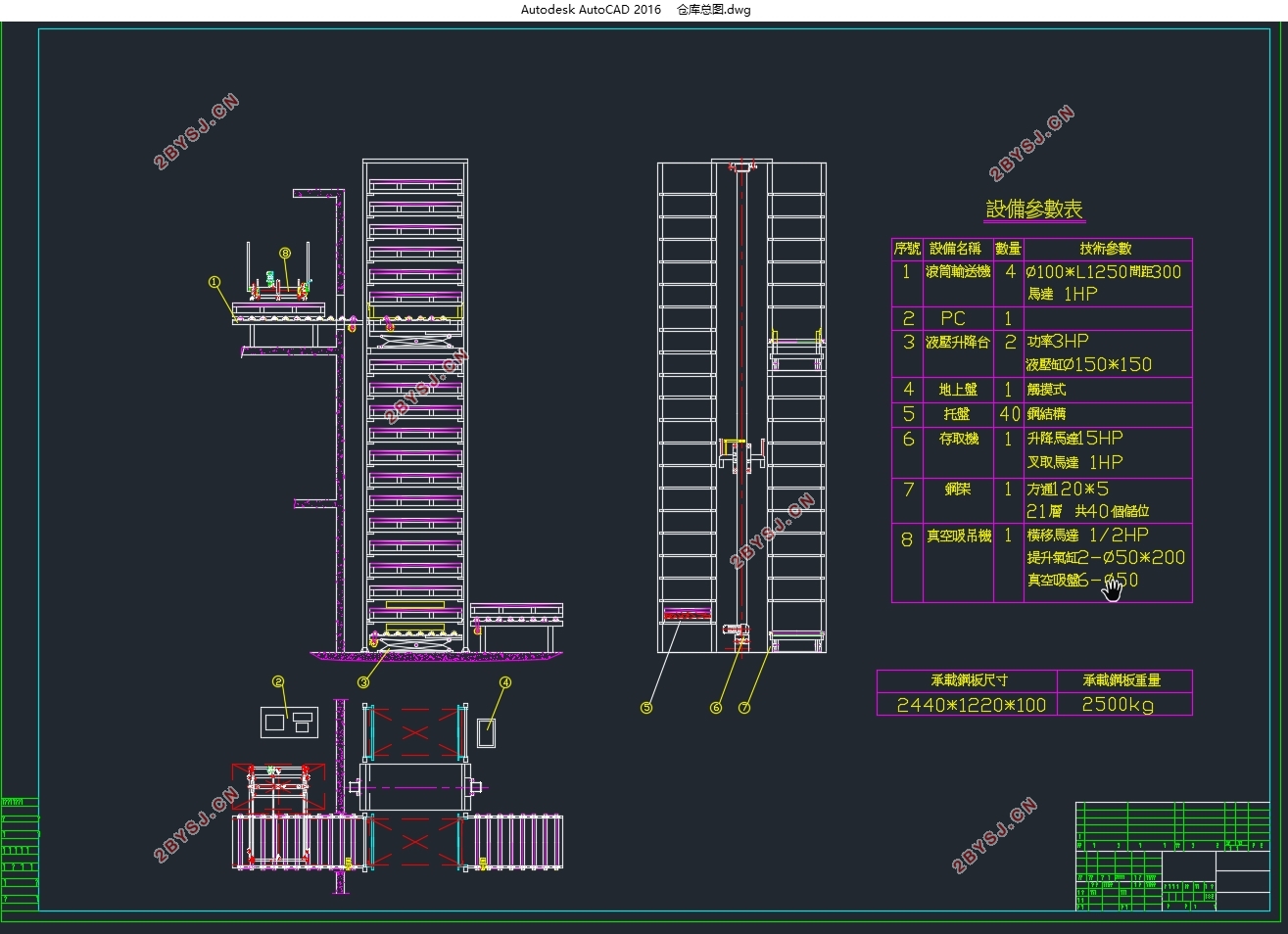

随着我国国民经济的快速发展,人类的生产生活方式趋于集中,城市的规模逐渐变大,人在城市里的生存空间却越来越小,仓储物流的立体化集中化就变的越发重要。立体仓库为现代的物流系统重要部分之一,是多层的存放货物的高架仓库,主要由:控制与管理系统、物流升降平台、计算机管理控制系统、高位货架、出入库以及其他得辅助设备组成。

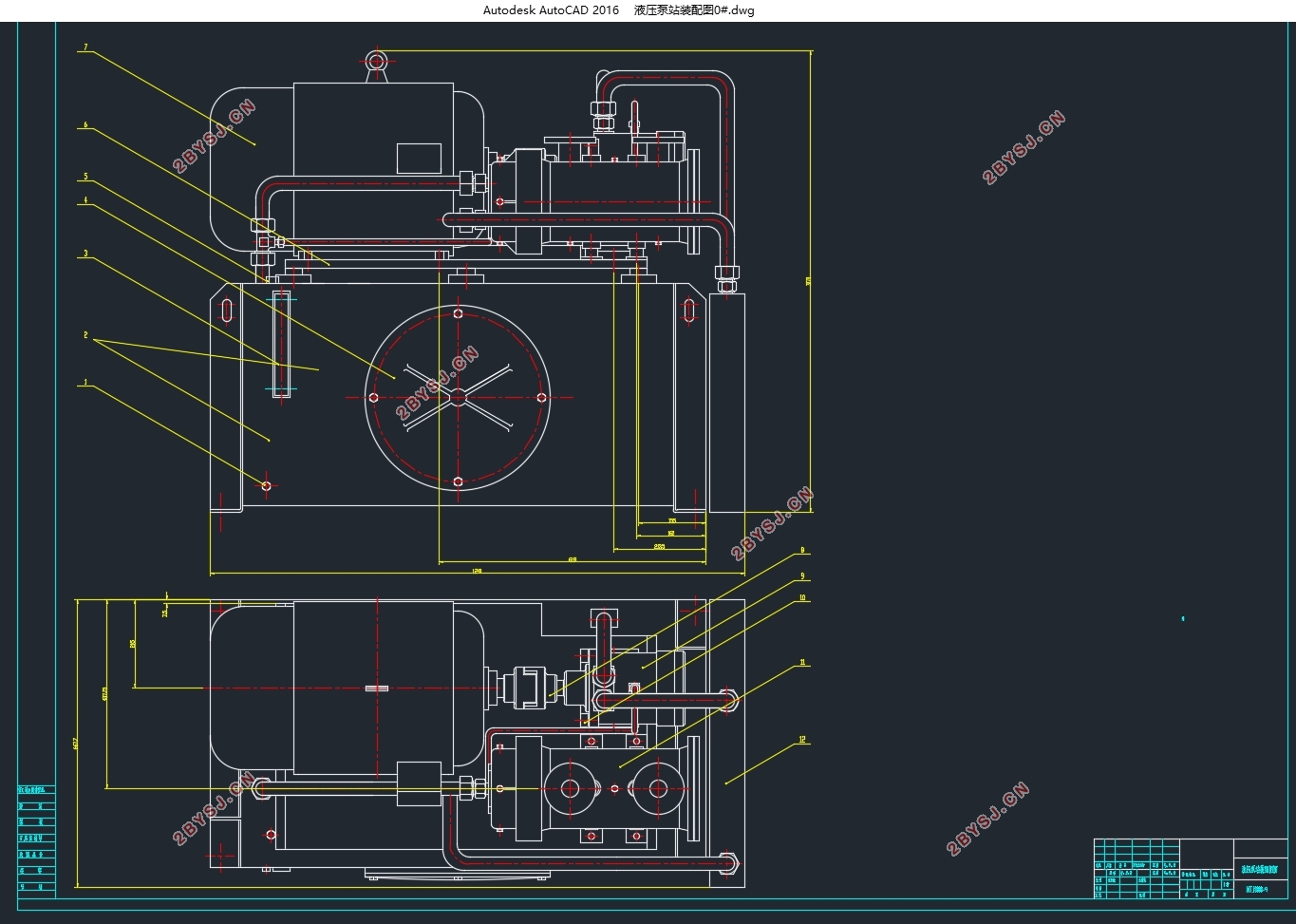

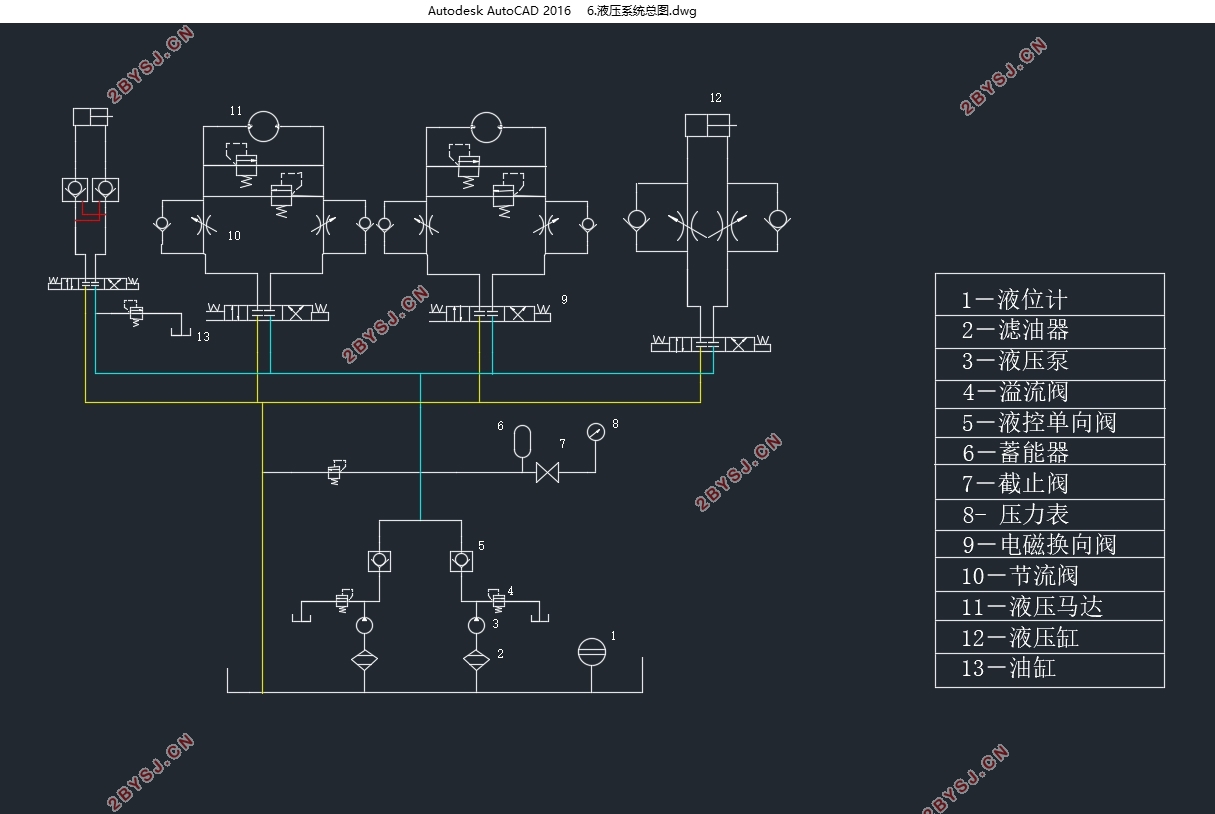

其中重点研究的是基于立体仓库的物流升降平台的设计与使用。文章设计了立体仓库的物流升降平台的支撑结构并校核通过。设计了物流升降平台中液压系统的横向移动、纵向推送和提升运动的系统,并计算选取了相应的液压系统和元件。画出了液压系统的原理图,液压站示意图,液压缸图与整体示意图。其中物流升降平台的货架是可以堆叠增加层数的,由钢结构组成,增加了仓储容量的可调性。而货物从入货口由传送带送入仓库,也可由传送从仓库送到出货口,实现货存取方便性提高。

关键词:立体仓库。结构设计。液压升降平台。物流。

ABSTRACT

With the rapid development of China's national economy, human production and lifestyle tend to focus on the scale of the city gradually become larger, people in the city's living space is getting smaller and smaller, three-dimensional storage of logistics become more important The Three-dimensional warehouse is an important part of modern logistics system, is a multi-storey storage of goods warehouse system, by the control and management system, high shelves, logistics platform, warehousing, storage, computer management and control systems and other auxiliary equipment composition.

Which focuses on the study is based on the three-dimensional warehouse logistics platform design and use. This paper designs the support structure of the logistics platform of the three-dimensional warehouse and checks and passes it. The system of lateral movement, longitudinal pushing and lifting movement of the hydraulic system in the platform is designed and the corresponding hydraulic system and components are calculated. The hydraulic system schematic diagram, hydraulic cylinder diagram, hydraulic station map and tank welding map. Which is the platform of the logistics platform can be stacked to increase the number of layers, composed of steel structure, increasing the storage capacity of the adjustable; and the goods from the mouth into the warehouse by the conveyor belt can also be sent from the warehouse to the export port .To achieve the convenience of cargo access to improve.

KEY WORDS: three-dimensional warehouse; structural design;

hydraulic lifting platform; logistic

2.3立体仓库的设计参数.

仓库货架设计尺寸50m×6m×6m。

最大载货质量(货位)为1800kg。

工作台质量为 600kg。

仓库共四层,每层可排多个货位(可自主叠加层数),仓库通过人工直接控制。

仓库载货板提升时间 10s。

下层载货板横移时间 10s。

2.4立体仓库结构设计的规范

立体仓库大体框架结构有:前、后横梁,前、后支撑柱与纵梁。其传动系统安装于支撑框架的纵梁和后立柱上。包含传动的链条链轮、液压缸、链条张紧装置和钢丝绳等。载货板与钢丝绳相相互连接进行提升。载货板在下层时,通过电机和导轨进行横移。为了该装置的良好的运行。立体仓库须需要足够的强度与刚度。

目 录

摘要..................................................I

ABSTRACT................................. ............II

一.绪论...............................................1

1.1课题研究的内容与意义..............................1

1.2国内与国外的发展概况....................................2

二.立体仓库的总体设计..............................3

2.1立体仓库选型........................................3

2.2立体仓库提升方式的选择..............................5

2.3立体仓库的设计参数..................................6

2.4立体仓库结构设计的内规范........................7

三.立体仓库支撑框架设计................................7

3.1立体仓库中升整体统的工作原理 ..........................7

3.2立体仓库钢结构设计..................................9

3.2.1支撑柱设计.....................................10

3.2.2横梁受力分析...................................13

3.3载货板受力分析校核.................................18

四.立体仓库的传动系统.................................21

4.1载货板提升装置设计.................................21

4.1.1升降传动系统设计...............................21

4.1.2升降液压系统设计...............................24

4.1.3升降液压系统链轮设计...........................24

4.2平移液压系统设计...................................27

4.3物品推送系统设计...................................31

4.4液压泵站设计.......................................32

五.结论和展望........................................33

5.1结论...............................................33

5.2不足之处与未来展望.................................33

参考文献................................................35

致 谢..............................................36