液压挖掘机能量回收方案设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

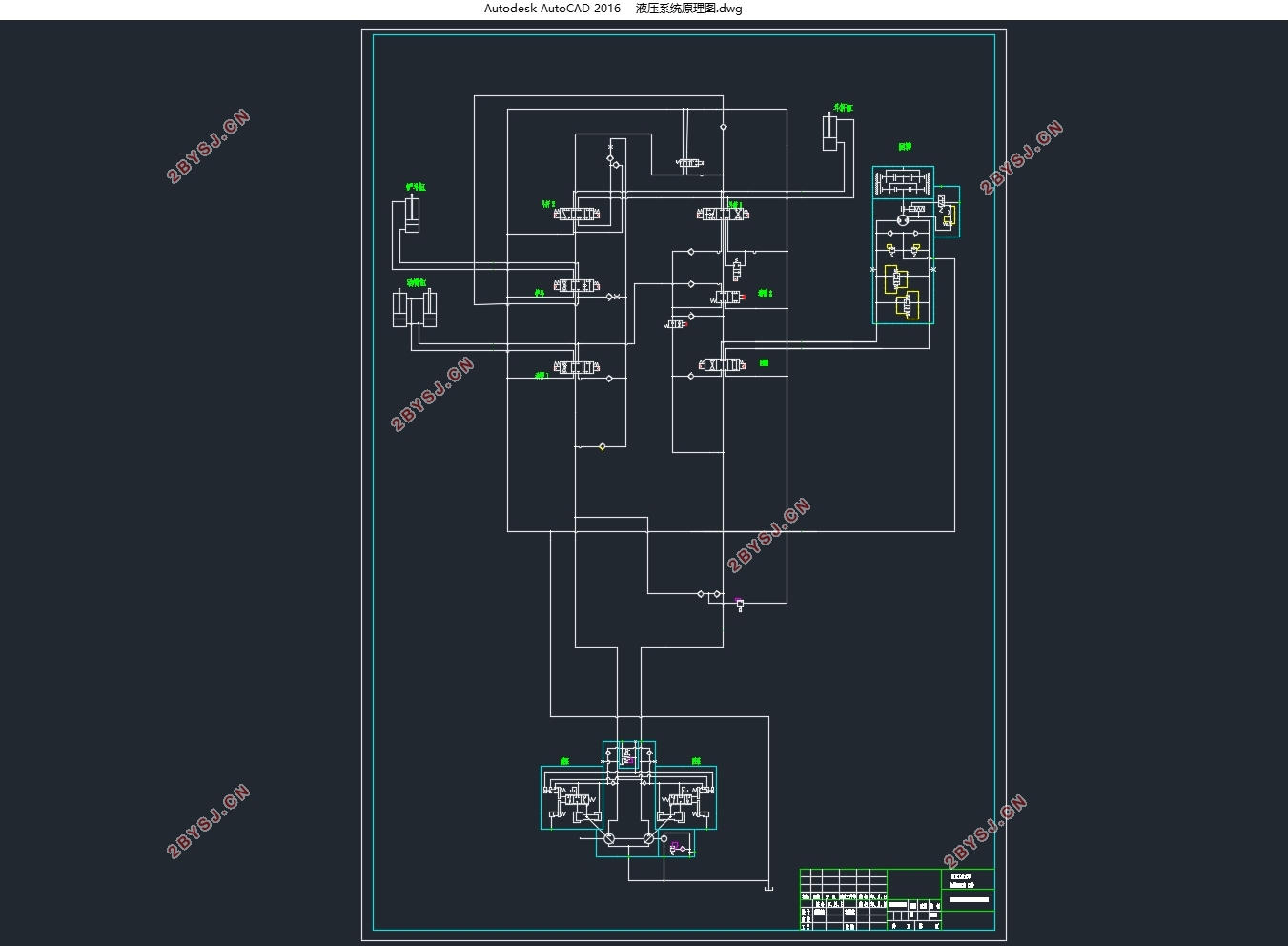

液压挖掘机能量回收方案设计(含CAD图)(论文说明书17000字,CAD图2张)

摘要

目前传统液压挖掘机的节能技术研究已经比较成熟,而能量回收是进一步降低液压挖掘机燃油消耗和废气排放的有效途径,对改善挖掘机低效率,高排放的现状具有重要意义,相关的研究还可为其他工程机械的能量回收提供参考。

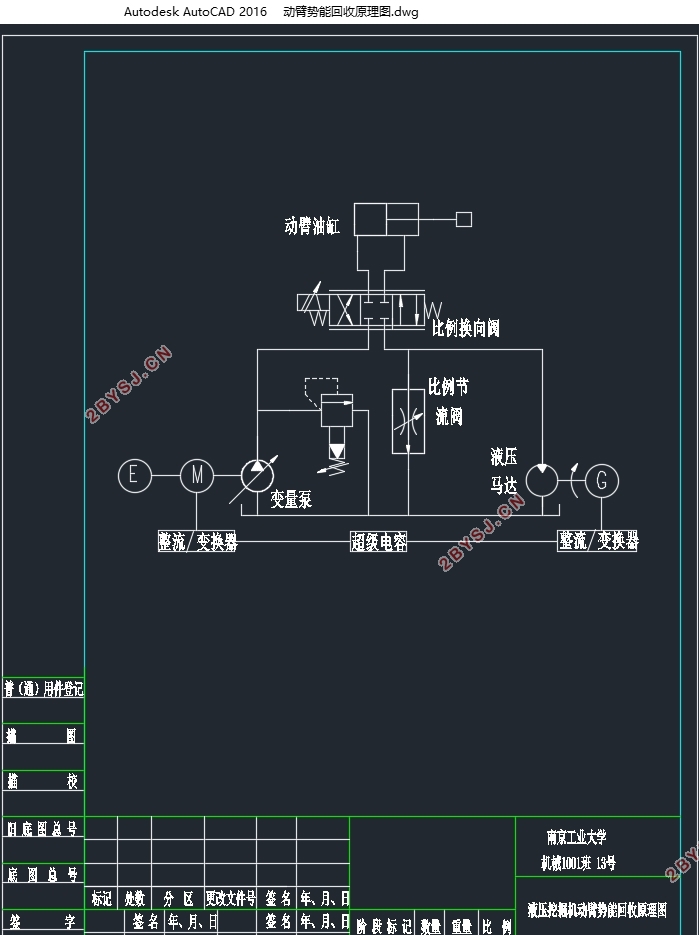

回收利用的能量主要包括动臂下降时的势能和回转制动时的动能。本文主要针对液压挖掘机动臂电气式能量回收系统的结构,以液压马达-发电机单元作为其能量回收单元,建立了能量回收单元的数学模型,提出了能量回收单元的转速控制方法;考虑到液压马达入口压力的变化,引入了扰动补偿以提高系统的抗干扰能力;在此基础上建立了相应的传递函数模型,并对设计的控制方法进行了仿真研究。

另外本文还研究了对动臂操作性具有主导性影响的能量回收系统控制方法。结合系统结构和特点提出了三种控制方法:直接转速控制,通过控制液压马达-发电机单元的转速节动臂液压缸速度,节流阀基本处于全开状态;负载压力控制,通过节流阀调节动臂液压缸度,根据负载压力反馈确定单元的目标转矩;节流阀压差控制,也通过节流阀调速,但根据节流阀压差闭环控制确定单元的目标转矩。根据对动态性能的分析和比较,论证了节流阀压差控制具有最优的频响和阻尼特性。

关键词:液压挖掘机 动臂势能 回转制动 能量回收

Design on Hydraulic Excavator Energy Recovering System

ABSTRACT

In these years, the research of energy saving technology of traditional hydraulic excavatoris rather mature,but energy recovery is an effective approach to further reduce the fuel consumption and emission of hybrid excavators.It is helpful for the low efficiency and heavy pollution of excavators in current. The involved results can also provide the energy recovery research of other construction machinery with references.

The energy this system saves are gravitational potential energy generated during the boom falling process and kinetic energy generated during the swing braking process.According to the construction of the electrical energy recovery system of a hydraulic excavator boom, a mathematical model of the energy recovery unit was established by selecting the hydraulic motor-generator unit as the energy recovery unit, and a speed control method of the energy recovery unit was proposed. Considering pressure changes at the inlet of the hydraulic motor, the disturbance compensation was introduced in order to improve the anti-interference capability. The corresponding transfer function models was established on the basis of the study above,and the simulation study for the control method of system design was operated as well.

In addition,three control methods are proposed and researched according to the structure and characteristics of the energy recovery system. Direct speed control method governs the boom velocity by controlling the rotational speed of the hydraulic motor-generator element directly and the throttle is almost kept opening totally. Load pressure control method governs the boom velocity by controlling the opening of the throttle and the object electromagnetic torque of the generator is given by the feedback of loaded pressure. Pressure drop control method also governs the boom velocity with the throttle, and the generator torque is determined by the feedback of pressure drop over the throttle.Concluding that the pressure drop control method has the best frequency response and damping ratio by comparing and analyzing their dynamic performances.

Key words:hydraulic excavator; arm potential energy; swing braking; energy recovery

目录

摘要 I

ABSTRACT II

第一章 绪论 1

1.1 挖掘机发展史及国内外发展状况 1

1.1.1 挖掘机发展史 1

1.1.2 挖掘机国内发展状况 1

1.1.3 国外发展状况 2

1.2 挖掘机节能研究意义 3

1.3 液压挖掘机节能研究现状 4

1.3.1 挖掘机液压系统节能研究 4

1.3.2 挖掘机能量回收系统研究现状 4

第二章 挖掘机能量回收系统结构设计 8

2.1液压系统节能 8

2.1.1正流量控制系统 8

2.1.2 负流量控制系统 9

2.1.3 负载敏感控制系统 9

2.2 动臂势能回收系统 11

2.2.1 动臂势能回收系统设计要求 11

2.2.2 动臂势能回收系统原理 11

2.3 回转能量回收系统 12

2.3.1回转能量回转系统设计要求 12

2.3.2回转能量回收系统原理 13

2.4 本章小结 14

第三章 动臂能量回收系统研究 15

3.1 动臂能量回收系统建模 15

3.1.1 永磁发电机模型 15

3.1.2 液压缸模型 17

3.1.3 液压马达-发电机单元模型 19

3.2 动臂能量回收仿真研究 22

3.3 能量回收系统控制方法 24

3.3.1直接转速控制 25

3.3.2负载压力控制 26

3.3.3节流阀压差控制 27

3.4 本章小结 28

第四章 总结与展望 29

4.1 工作总结 29

4.2 主要研究工作 29

4.3研究展望 29

参考文献 31