转向臂轴参数化设计与有限元分析

无需注册登录,支付后按照提示操作即可获取该资料.

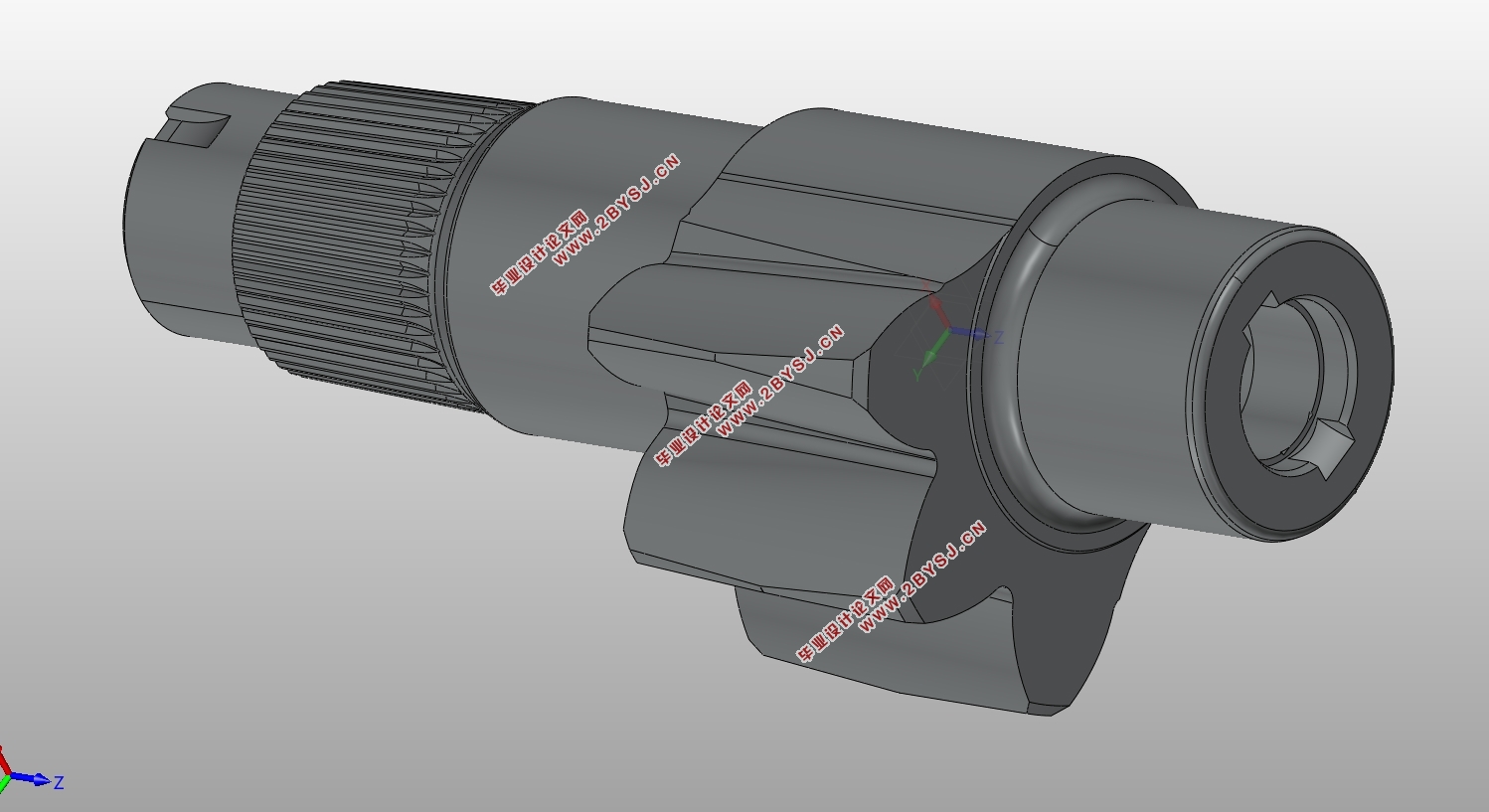

转向臂轴参数化设计与有限元分析(任务书,开题报告,外文翻译,论文说明书15000字,三维模型,频率分析)

摘 要

汽车转向系统中,转向臂轴扮演着重要角色,转向臂轴是转向器中关键的零部件[1],部分转向臂轴的齿扇不是正常的圆柱直齿轮,利用常规的方法建模十分复杂。

本文根据生产过程中企业的实际需求,利用C#语言对SolidWorks进行二次开发,编写相应的软件,对市场占比较大的循环球式转向器的转向臂轴进行参数化建模,用户通过人机友好交互的图形化界面输入参数,就能自动生成相应的模型和出相应工程图。节省了产品设计所需的时间,提高了产品设计的效率,使企业的个性化需求得到了满足,所编写的软件对于相关企业用户具有重大意义。转向臂轴扇齿的强度对转向器的强度有重大影响,对其结构进行分析和改进是转向器设计中的重要部分,本文使用SolidWorks的有限元分析插件---Simulation对转向臂轴三维模型进行静应力分析和模态分析,找出其工作过程中应力集中的地方与材料的屈服极限相比较来判断设计是否合格,如果不合格则采取相应的措施对其进行改进;求出转向臂轴的共振频率,避免与周围的物体发生共振。

本文设计了一套转向臂轴参数化设计系统,并根据实际工况对转向臂轴进行了有限元分析。

关键词:SolidWorks,参数化,有限元,转向臂轴

Abstract

The steering gear is an important part of the steering system of the car. The steering arm shaft is not a normal cylindrical spur gear. It is very complicated to model by conventional methods.

According to the actual needs of enterprises in the production process, this paper uses C# language to carry out secondary development of SolidWorks, and writes corresponding software to parametrically model the steering arm shaft of the recirculating ball steering gear with large market share. The user passes the man-machine. The friendly interactive graphical input parameters can automatically generate the corresponding model and corresponding engineering drawings. It saves the time required for product design, improves the efficiency of product design, and satisfies the individualized needs of the enterprise. The software written is of great significance to related enterprise users. The strength of the steering arm shaft teeth has a great influence on the strength of the steering gear. The analysis and improvement of its structure is an important part of the steering gear design. This paper uses the finite element analysis plug-in of SolidWorks---Simulation on the three-dimensional model of the steering arm shaft. Perform static stress analysis and modal analysis to find out where the stress concentration in the working process is compared with the yield limit of the material to judge whether the design is qualified. If it is not qualified, take corresponding measures to improve it; Resonance frequency to avoid resonance with surrounding objects.

In this paper, a set of steering arm shaft parametric design system is designed, and the finite element analysis of the steering arm shaft is carried out according to the actual working conditions.

Key Words:SolidWorks;parameterization;finite element analysis;steering arm shaft

论文研究内容

本文根据某企业的实际需求,以Visual Studio2015为集成开发环境,使用C#编程语言调用SolidWorks的API进行二次开发,编写了转向臂轴参数化建模软件,不仅能够生成转向臂轴的三维模型而且可以生成相应的工程图。本文对其思路和实现方法做了详细的阐述,对软件的使用过程做了简单介绍。最后根据工程中转向臂轴实际的工况进行静应力分析和模态分析,针对仿真的结果对转向臂轴的结构设计提出优化建议好改进措施。

目录

摘 要 I

Abstract II

1 绪论 1

1.1 研究的背景和意义 1

1.2 论文研究内容 1

2 转向臂轴介绍 2

2.1 转向臂轴功用 2

2.2 转向臂轴扇齿形式对转向器性能的影响 2

3 SolidWorks二次开发技术与API应用 4

3.1SolidWorks二次开发形式 4

3.2 SolidWorks API对象概述 5

3.3 SolidWorks参数化设计方法 6

3.4开发环境的搭建 7

4 转向臂轴参数化设计系统的开发 9

4.1系统工作流程 9

4.2UI交互模块 10

4.3尺寸驱动模块 13

4.4齿扇建模模块 18

4.5本章小结 25

5 转向臂轴有限元分析 25

5.1Simulation有限元分析 25

5.1.1有限元分析术语 26

5.1.2有限元分析基本流程 26

5.2转向臂轴静应力仿真 28

5.2.1前处理 28

5.2.2结果分析 30

5.3转向臂轴模态分析 32

6结论与展望 34

6.1主要结论 34

6.2研究工作展望 35

致 谢 37