风电回转支承试验台驱动器:液压系统(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

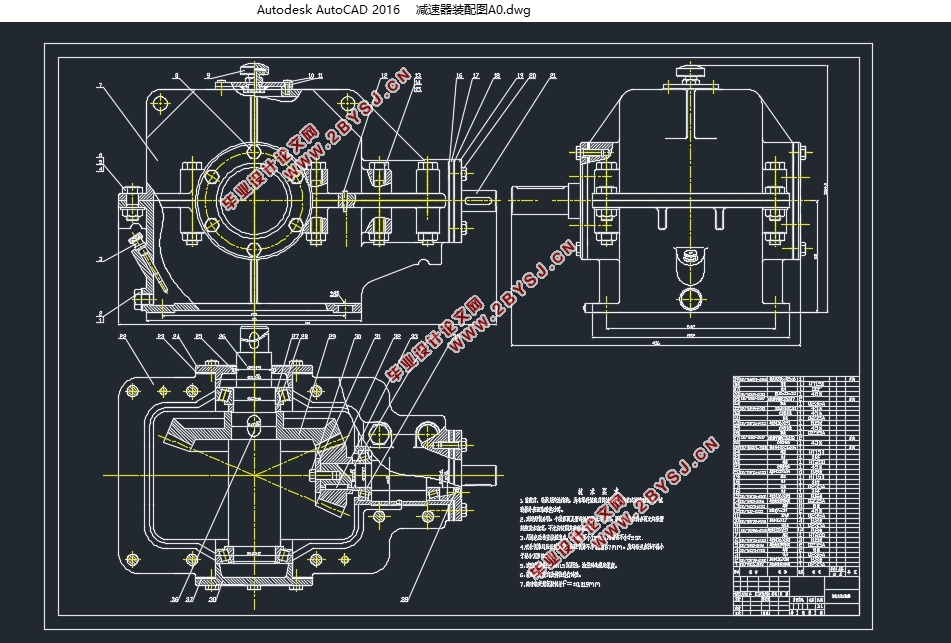

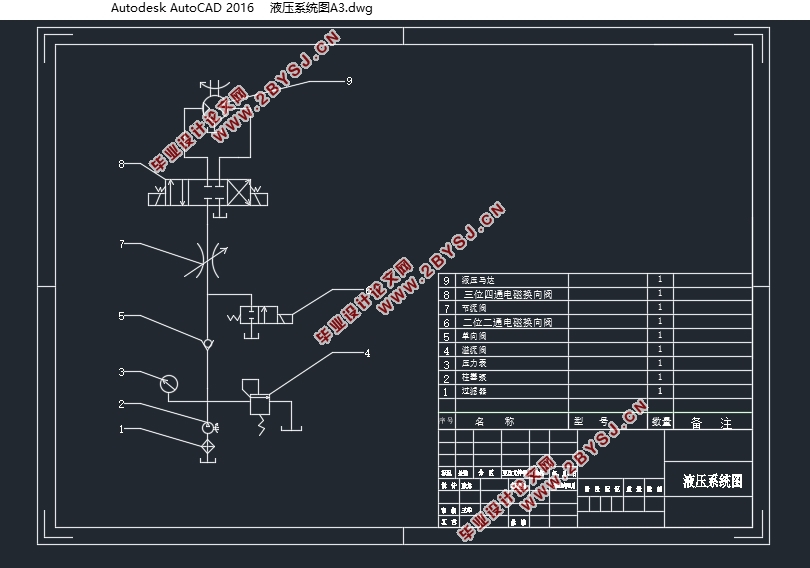

风电回转支承试验台驱动器:液压系统(含CAD图)(论文说明书11000字,CAD图2张)

摘 要

回转支承是一种可以同时承受较大的轴向负荷、径向负荷和倾覆力矩的大型轴承。回转支承相当于设备的运动关节,而液压系统就相当于设备的动力传输。一个完整的液压系统都是由动力元件、控制元件、执行元件、辅助元件和液压油五个部分组成。由于液压技术的各种优点,它以及在国民经济的各个行业扮演一个重要的角色。由于国内外液压元件在结构特点、型号编制方面的不同,给使用液压设备的工程技术人员和操作人员带来了诸多不便,然而液压元件的工作原理是不变的。

本文结合风电回转支承试验台驱动器的要求,设计液压系统的控制回路。并通过分析比较液压控制系统的工作原理和组成,以及各种常用的液压元件的工作原理、结构、型号编制、选用注意事项 ,来选择液压控制系统中液压泵、液压阀等液压元件的型号。

最后再校核自己的选型,最终满足任务要求。

关键词:回转支承 控制回路 液压元件

Rotary supporting test bench for wind power:Hydraulic system

Abstract

The rotary bearing is a large bearing which can bear large axial load, radial load and overturning moment simultaneously. The rotary support is equivalent to the motion of the joint, and the hydraulic system is equivalent to the power transmission of the equipment. A complete hydraulic system is composed of five parts: the power element, the control element, the executive component, the auxiliary component and the hydraulic oil. Because of various advantages of hydraulic technology, it plays an important role in various industries of national economy. Due to the different hydraulic components at home and abroad in terms of structure, model establishment, to use hydraulic equipment engineering and technical personnel and operation personnel brings a lot of inconvenience, but the working principle of hydraulic components is unchanged.

In this paper, the control circuit of hydraulic system is designed according to the requirement of the wind power rotary bearing test bench. And through the comparison and analysis of the hydraulic control system principle of work and the composition, and the working principle of a variety of commonly used hydraulic components, structure, model establishment, selection considerations, to select the hydraulic control system in hydraulic pump, hydraulic valve, hydraulic components model.Finally check their selection, and ultimately meet the requirements of the task.

Keywords: Slewing bearing Control loop Hydraulic components

目录

摘 要 I

第一章 引言 1

1.1 风电回转支承试验台的简介 1

1.2 液压系统的国内外研究状况 2

1.2.1 液压系统的国外研究现状 2

1.2.2 我国液压技术的发展状况 3

1.3 液压系统的发展趋势 4

1.4 课题研究的目的和意义 5

第二章 试验台驱动器液压系统设计 6

2.1 液压系统的组成 6

2.2 液压系统的优缺点 6

2.3 液压系统设计 7

2.3.1 明确设计要求 7

2.3.2 技术参数 8

2.4 确定液压的基本回路 8

2.4.1 压力控制回路 8

2.4.2 速度控制回路 11

2.4.3 方向控制回路 12

2.5 液压泵的选择 12

2.6 马达控制回路图 15

第三章 液压元件的选型计算 17

3.1 马达的数据计算 17

3.2 液压泵的数据计算 17

3.3液压阀的选择计算 18

3.4管道尺寸的计算 18

3.5 油箱容量的确定 20

第四章 液压系统性能验算 22

4.1 液压管路系统压力损失的计算 22

4.1.1 验算压力损失 22

4.1.2 验算温升 23

4.1.3 验算液压冲击 24

参考文献 27

致谢 29