1.5MW风电机组齿轮箱设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

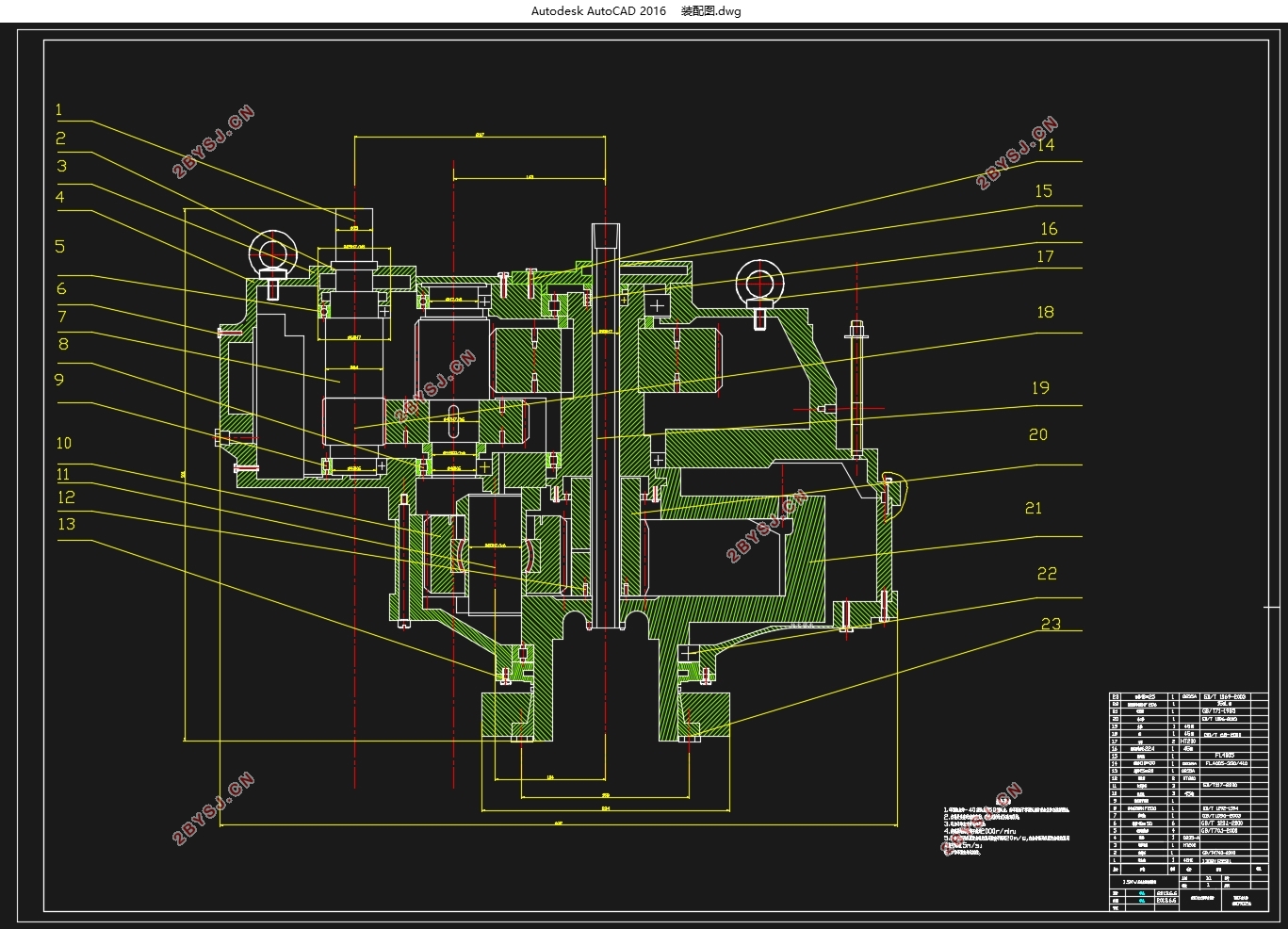

1.5MW风电机组齿轮箱设计(含CAD零件图装配图)(任务书,开题报告,论文说明书15000字,CAD图5张)

摘 要

摘要:近年来,随着人们对风力发电越来越重视,风电产业迅猛发展。目前,水平轴风力发电机在风力发电中仍占据重要位置,而由于风电齿轮箱的故障率较高,风电齿轮箱设计制造的关键技术一直是困扰我国乃至世界风电快速发展的重要因素,特别是随着风力机单机容量的不断增大,大型风电齿轮箱设计制造需要考虑的因素越来越多。风电机组在运行过程中,齿轮箱往往过早损坏,其原因主要是风电齿轮箱轴承在复杂载荷作用下的寿命难以估算,导致轴承过早损坏,另一方面,尽管目前对轴承寿命的计算方法繁多,但并没有能准确评估现代轴承寿命的计算方法。此外,对风电齿轮箱的强度计算方法和复杂载荷的处理也不尽完善。因此,对大型风电齿轮箱装置展开系统、深入的分析研究对风电的发展具有重要意义。风电产业的飞速发展促成了风电装备制造业的繁荣,风电齿轮箱作为风电机组的核心部件,倍受国内外风电相关行业和研究机构的关注。但由于国内风电齿轮箱的研究起步较晚,技术薄弱,特别是兆瓦级风电齿轮箱,主要依靠引进国外技术。因此,急需对兆瓦级风电齿轮箱进行自主开发研究,真正掌握风电齿轮箱设计制造技术,以实现风机国产化目标。

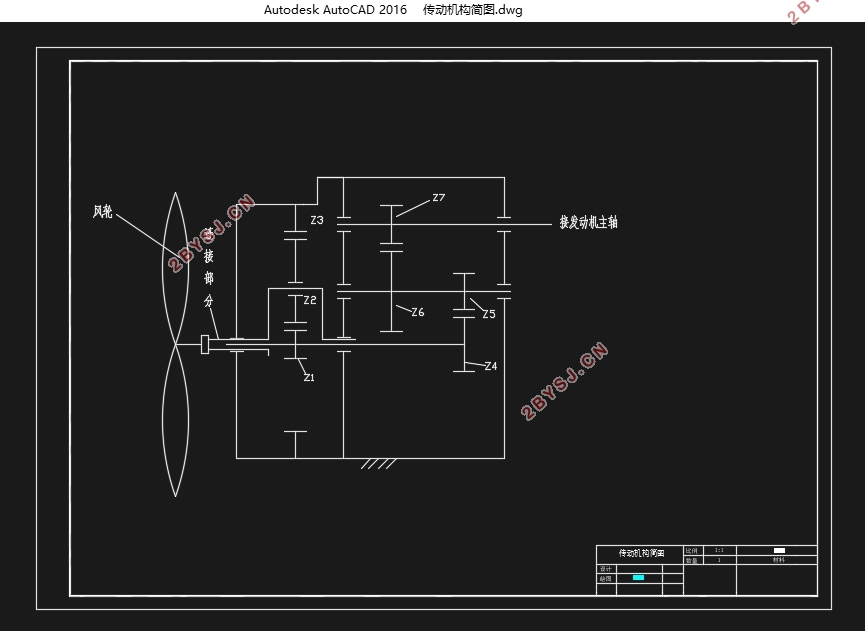

首先,根据风电齿轮箱承受载荷的复杂性,对其载荷情况进行了分析研究,确定齿轮箱的机械结构。选取两级行星派生型传动方案,通过计算,确定各级传动的齿轮参数。

其次,对行星齿轮传动进行受力分析,得出各级齿轮受力结果。依据标准进行静强度校核,结果符合安全要求。

最后,绘制CAD装配图,并确定恰当合理参数。

关键词:风电齿轮箱;载荷;结构设计。

1.5 MW wind turbine gearbox design

ABSTRACT

ABSTRACT:In recent years,wind power industry has been rapidly developing along with the wind power generation drawing more and more attention.At present,horizontal axis wind turbine has the dominant position in wind turbine generator system(WTGS).The key design and manufacturing technology of gearboxes have become an important factor for restricting the development of wind power.With the wind turbine’s capacity increasing, mole and more complications must be considered in large—scale wind turbine’s design and manufacturing.The gearbox is damaged too earlier for WTGS in life expectancy.The main cause is that the bearing lifetime can’t be estimated accurately when the load is very complicated.On the other hand,despite there are many calculating methods.bearing lifetime not be estimated well and truly.In addition, the calculating method of load capacity of gears and the method of dealing with complicated load need to be improved,SO it’S very important to research the gearbox of large-scale wind turbines systematically.The rapid development of wind power industry lead to the prosperity of wind power equipment manufacturing industry.As the core component of wind turbine, the gearbox is received much concern from related industries and research institution both at home and abroad.However, due to the domestic research of gearbox for wind turbine starts late,technology is weak,especially in the gearbox for MW wind turbine, which mainly relied on the introduction of foreign technology.Therefore,it is urgent need to carry out independent development and research on MW wind power gearbox, and truly master the design and manufacturing technology in order to achieve the goal of localization.

Firstly, The load Cases of gearbox for wind turbines ale analyzed,and the interrelation of loading cycle numbers under different torque levels is deduced according to the curve of materials’fatigue.the mechanical structure of gearbox is determined.The two-stage derivation planetary transmission scheme is selected.The gear parameters of every stage transmission is calculated.,and the force analysis results is obtained.

Then, the static strength check of tooth surface contact is implemented according to related standard.The result shows that it is accord with safety requirements.

Finally Draw CAD drawings, and determine appropriate reasonable parameters.

KEYWORDS:Gearbox for Wind Turbine;Load;Structure Design.

目 录

摘要 . .... .. ................................................I

ABSTRACT......................................................II

第1章 引言......................................................1

1.1国内外发展现状与趋势......................................1

1.1.1风力发电国内外发展现状与趋势.........................1

1.1.2 风电齿轮箱的发展现状................................3

1.1.3我国风电齿轮箱的设计制造技术的现状...................4

1.1.4存在问题与展望.......................................5

1.2齿轮箱设计制造技术.........................................6

1.3润滑、冷却和加热系统.......................................6

1.4课题研究的意义.............................................7

1.5论文的主要内容.............................................8

第2章 齿轮箱机构设计..........................................9

2.1增速齿轮箱方案设计.........................................9

2.2齿轮参数的确定.............................................12

2.2.1行星轮系的齿轮参数...................................12

2.2.2 圆柱级齿轮参数.......................................16

2.3受力分析与静强度的校核.....................................18

2.3.1受力分析.............................................18

2.3.2低速级外啮合齿面静强度计算...........................19

2.4 齿轮传动强度的校核计算.....................................20

2.5本章小结...................................................24

第3章 传动轴的设计.......................................25

3.1 高速轴的设计...............................................25

3.2低速轴的设计...............................................25

3.3中间轴的设计...............................................26

第4章 齿轮箱其他零部件的选用.................................27

4.1 齿轮箱的加工及工艺........................................27

4.1.1齿轮箱零部件的加工与装配............................27

4.1.2 齿轮箱的加工工艺过程................................27

4.2齿轮的机械加工............................................28

4.3轴类零件的加工............................................29

4.4 轴承的选用................................................30

4.5齿轮、轴承的润滑机理.......................................31

4.6 本章小结..................................................31

第5章 齿轮箱的使用及其维护....................................32

5.1 安装要求..................................................32

5.2 定期更换润滑油............................................32

5.3齿轮箱常见故障............................................32

第6章 结论..............................................33

参考文献..................................................34

致谢..............................................................36