基于NX的数控铣床程序开发以及加工仿真(含UG三维零件图,加工代码)

无需注册登录,支付后按照提示操作即可获取该资料.

基于NX的数控铣床程序开发以及加工仿真(含UG三维零件图,加工代码)(开题报告,外文翻译,论文说明书10000字,UG三维图1张)

摘要:随着科学技术的迅猛发展,现代制造业正面临着一场工业技术革命。数控技术及数控机床在当今机械制造业中发挥了重要作用,在国家基础工业现代化中也直接彰显了战略性作用,并已成为传统机械制造工业提升改造和实现自动化、柔性化、集成化生产的重要手段和标志。数控技术及数控机床的广泛应用,使机械制造业发生了历史性的变化,其生产结构、产品类型、档次以及生产方式都进一步完善。现代加工车间最重要的设备就是数控机床,现代的CAD/CAM、FMS、CIMS、敏捷制造以及智能制造技术,都需要数控技术作为基础。

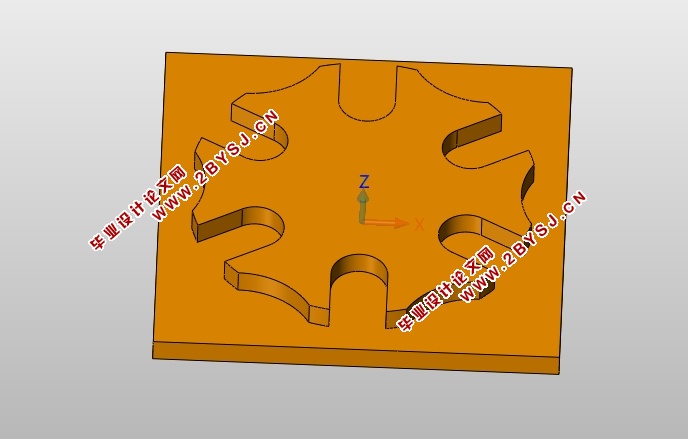

本次毕业设计主要是使用NX8.0对于给定的零件进行建模、仿真,再根据实训中心的数控铣床的特点,进行加工检验。本次毕业设计先运用NX根据要求制出零件的实体三维造型,并对这个给定的零件进行图形分析和工艺分析,确定它的加工方法和所需要的加工刀具等,确定好其工序,然后运用NX软件对零件进行相应的编程处理,在斯沃数控软件上模拟出数控加工过程,进行对比发现需要改进的地方,并及时优化处理。最后通过后处理生成的零件加工程序转化成铣床可以接受的加工代码,并在数控铣床上进行实际加工检验。

关键词:NX; 仿真; 数控技术

NX-based CNC milling program development and machining simulation

Abstract: With the rapid development of science and technology, modern manufacturing industry is facing an industrial technological revolution. CNC technology and CNC machine tools have played an important role in today's machinery manufacturing industry. They have also directly demonstrated the strategic role in the modernization of the country's basic industries and have become the traditional machinery manufacturing industry to upgrade and transform, realize automation, flexibility, and integrated production. Important means and signs. The wide application of numerical control technology and CNC machine tools has brought about historic changes in the machinery manufacturing industry, and its production structure, product types, grades, and production methods have been further improved. The most important equipment in modern machining workshops is CNC machine tools, modern CAD/CAM, FMS, CIMS, agile manufacturing, and intelligent manufacturing technologies, all of which require the foundation of numerical control technology.

The graduation project mainly uses NX8.0 to model and simulate the given parts, and then conducts inspection according to the characteristics of the CNC milling machine in the training center. The graduated design first uses NX to produce the solid three-dimensional shape of the part based on the requirements, and performs graphic analysis and process analysis on the given part, determines its processing method and required machining tools, etc., to determine the process, and then Using NX software, the parts are programmed accordingly, and the trajectory of the knife is simulated, and the comparison is made to find out where improvements need to be made, and the processing is optimized in time. Finally, the part processing program generated by the post-processing is converted into an acceptable machining code for the milling machine, and the actual machining inspection is performed on the numerically controlled milling machine.

Keywords: NX; Post-processing; CNC Technology

目 录

摘要 I

ABSTRACT II

1绪论 1

1.1课题的背景及意义 1

1.1.1课题的背景 1

1.1.2课题的意义 1

1.2课题的来源及目的 2

1.3数控技术的国内外发展趋势 3

1.3.1向高速度、高精度加工技术及装备发展 4

1.3.2向控制智能化、体系开放化方向发展 4

1.3.3向驱动并联化、网络化方向发展 4

1.3课题的主要研究内容 4

2相关技术基础及机床参数 5

2.1数控加工 5

2.2数控机床 5

2.3 数控编程 5

2.3.1手工编程 5

2.3.2自动编程 6

2.4FANUC数控系统 6

2.4.1程序的结构形式 6

2.4.2主要功能介绍 7

2.4.3用户宏程序 9

2.5 HM6-M03-01数控铣床以及各项参数 9

3 UG NX软件及后置处理器 10

3.1UG NX软件的概述 10

3.2UG NX软件的应用领域 10

3.3后置处理过程具备的条件 10

3.3.1刀具路径 10

3.3.2加工输出管理器 10

3.3.3事件生成器 11

3.3.4事件处理文件 11

3.3.5机床定义文件 11

3.4 UG 后置处理介绍 11

4 UG造型、后处理及仿真加工 13

4.1 实体三维造型 13

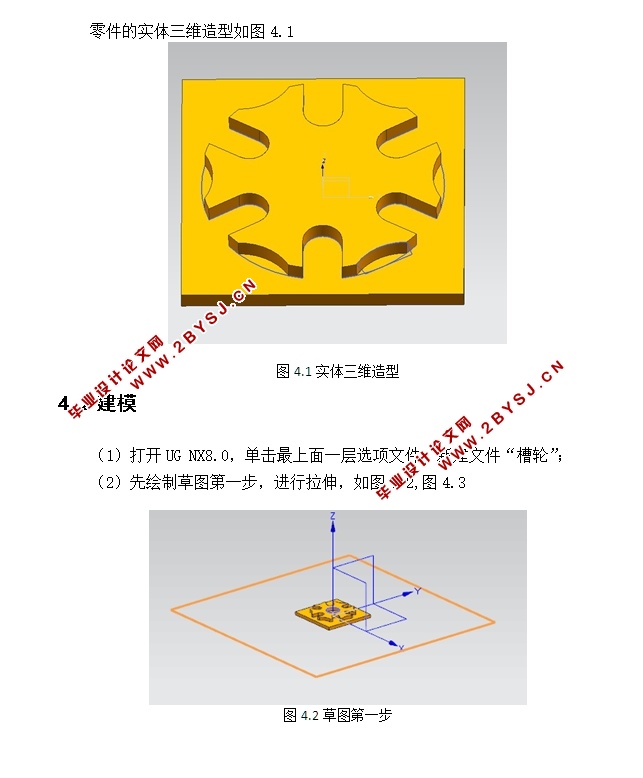

4.2建模 13

4.3后处理 15

4.3.1创建后处理文件 15

4.3.2机床参数定义 16

4.3.3程序和刀具路径 16

4.3.4输出设置 17

4.3.5添加后处理到模板文件 18

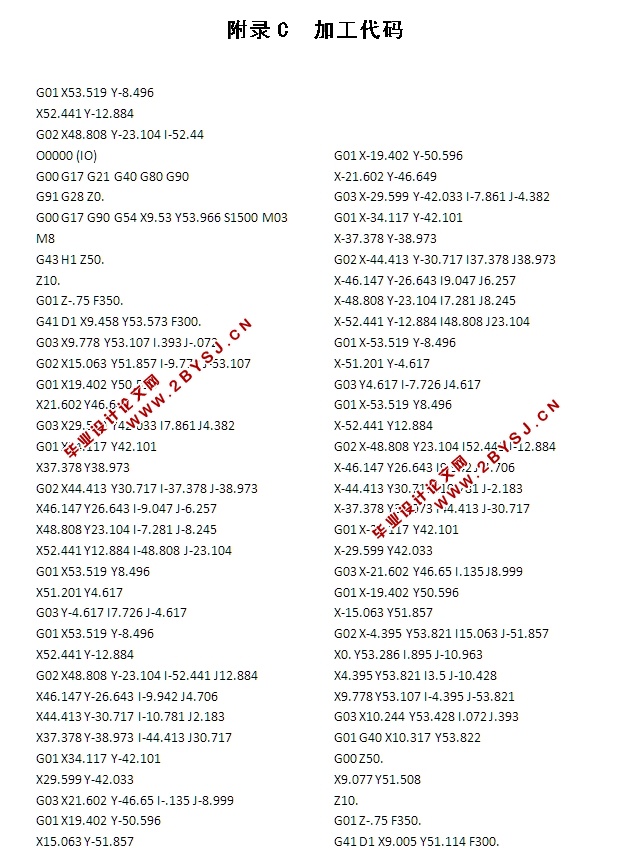

4.4输出NC代码并仿真加工 18

4.5导入机床进行加工验证 19

5 结论 21

参考文献 22

致谢 23

附录A英文文献 24

附录B中文翻译 37

附录C 加工代码 48