Φ76-Φ89mm新型圆形截面管材滚切机设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

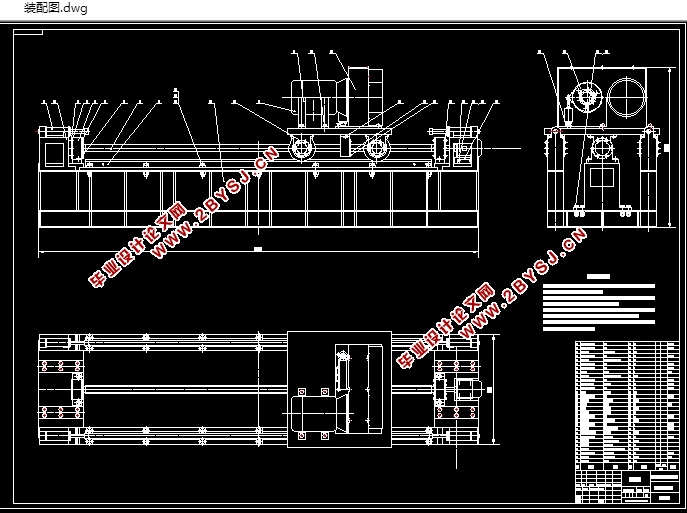

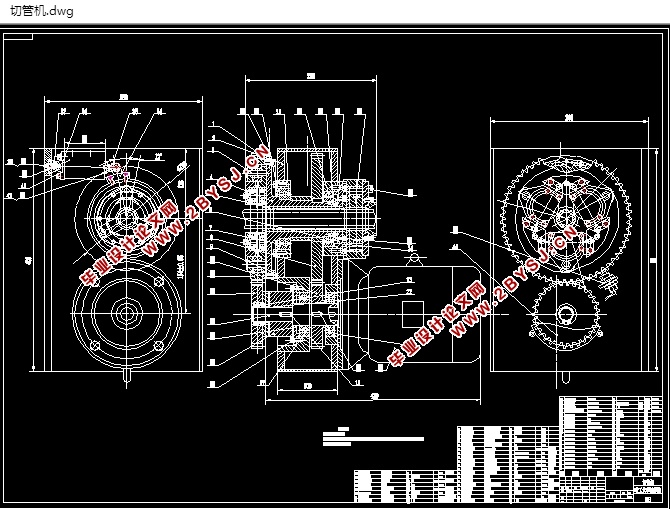

Φ76-Φ89mm新型圆形截面管材滚切机设计(含CAD零件图装配图)(任务书,开题报告,论文说明书14000字,外文翻译,CAD图纸4张)

摘 要

随着切割机的发展,采用滚切机在线切断管材是近几年在国外发展起来的新技术。这种滚切机是利用三把带有楔角的圆盘形滚切刀片,采用滚动压入的方法将管材切断。由于采用了滚压无屑剪切,刀具的滚切行程略大于管材壁厚即可切断管材,因而效率高(尤其是对于大直径管材)。可以实现小噪音、无切屑、小(无)毛刺切管,并可保证管材切口绝对垂直于管材轴线。从而可简化生产工艺、减少设备的投资、降低生产成本,并可改善生产环境,解决了长期困扰钢管企业的噪音问题。

我设计是端面凸轮式钢管在线滚切机,滚切式切断的工作原理是利用三把带楔角的碟形滚切刀片均匀的安装在刀头架上,刀头架由驱动齿轮带动旋转,齿轮由齿条驱动,端面凸轮推动齿条从而使刀头架进给的同时实现径向进给,刀片与被切管材接触后,除绕管材公转外,还绕自身中心轴旋转,在管材表面实现纯滚动,在径向进给系统的作用下逐渐将管材切断。这种切断方式可实现切口断面轮廓不失真。滚切式即近年来发展的旋转楔入法。

关键词 管材 滚切机 端面凸轮

Abstract

Along with the development of cutting machine, cutting machine adopts the roll online in recent years in foreign countries cut off the tubes are developed new technology. This kind of cutting machine is rolling by 3 to a wedge disc shape roll, the rolling pressure blade cut into the methods will pipes cut off. Since it is a rolling a chip less shear, the cutting tool roll-cut trip is slightly higher than the pipe wall thickness can be cut off, and high efficiency pipes, especially for large diameter tubes). Can realize the little noise, no scraps, small (no) burr cut tube, and can ensure the pipe in vertical pipe axis incision absolute. Thus, can simplify production technology, reducing equipment investment, reduce the production cost, and can improve the production environment, solved the problem of noise steel enterprises.

My design is section CAM tubular steel rolling cutting machine, get online cut off the work of principle is to use the wedge with three of the disc roll-cut blade even installed in frame on, cutter head frame is driven gear, gear rotating driven by rack drive, promoting rack and CAM section head into the frame to realize radial feeding, the blade was cut pipe after contact with, in addition to the revolution around the pipe outside, still around their own center axis rotation in pipes, achieving pure rolling, surface in radial feeding system under the function of the pipes cut off gradually. This cut way can realize incision section contour not distortion. Roll-cut type is rotating wedge method in recent years.

Keywords pipe roll cutting machine section CAM

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1课题背景 1

1.2国内外研究现状 3

1.2.1非剪切类的切断方法 3

1.2.2剪切类切断方法 4

第2章 方案确定 5

2.1旧型滚切机在实际应用中存在的问题 5

2.2设计原理 6

第3章 滚切机本体设计 10

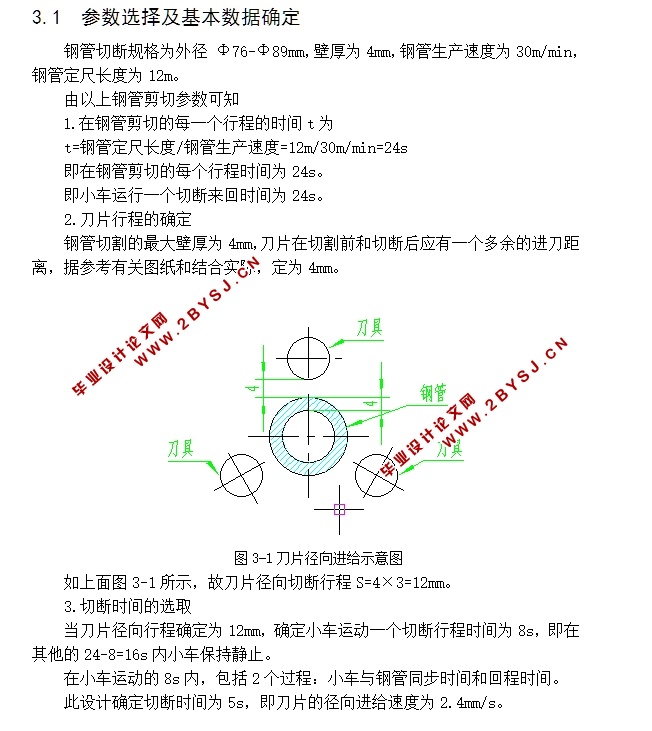

3.1 参数选择及基本数据确定 10

3.3 滚切力的计算 12

3.3.1 滚切力的理论分析 12

3.3.1.4 径向加工力的计算 13

3.3.2 切向加工力的计算 14

3.3.3 转盘轴及轴上部件 14

3.4 刀夹座的设计 15

3.5 齿轮参数选择及齿轮轴强度校核 16

3.7 进给架、进给环设计 20

3.8.1系杆架转动力矩 21

3.9本章小结 22

第4章 部件设计 23

4.1 夹紧装置设计 23

4.1.1夹紧装置液压缸的设计 24

4.1.2夹紧凸轮的设计 26

4.2 小车行走装置设计 27

4.2.1 小车动力传动方式的选择 27

4.2.2 小车主体的受力分析 27

4.2.4 行走小车电动机的选取 29

4.3 本章小结 30

结论 31

致谢 32

参考文献 33

附录1 34

附录2...