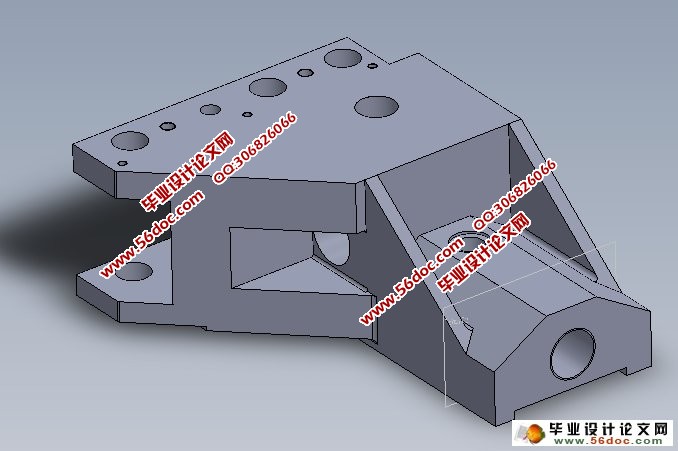

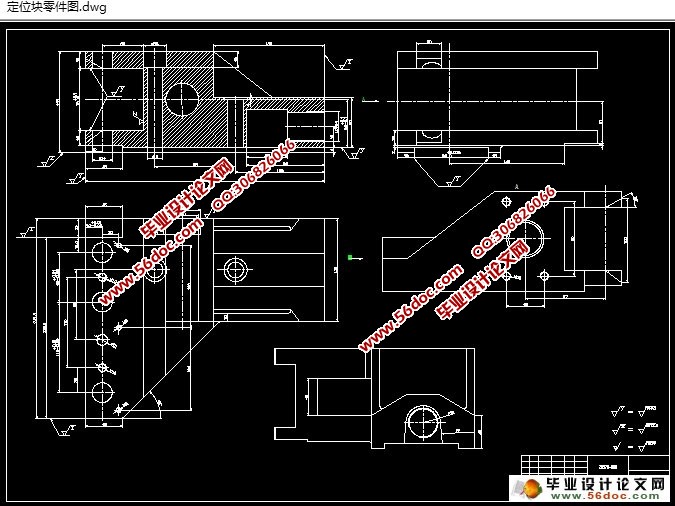

定位块Ⅱ加工工艺与其45孔和76槽加工夹具设计(CAD,SolidWorks)

无需注册登录,支付后按照提示操作即可获取该资料.

定位块Ⅱ加工工艺与其∅45孔和76槽加工夹具设计(CAD,SolidWorks)(任务书,开题报告,中期报告,论文说明书22000字,SolidWorks定位块三维图1张,CAD图8张)

The mechanical processes of Positioning blockⅡand the special fixture design of the 45 Hole & the 76 Notch

摘 要

零件加工工艺与夹具设计是机械加工制造中的重中之重,好的工艺规程和专用夹具可以提高生产率、保证高的加工精度,节省大量的人力和财力。

定位块是机械行业常见的一种零件,用途广泛,通常批量制造,因此,分析制定定位块的加工工艺和进行专用夹具设计是有必要的。在下文中,主要介绍了定位块的工艺过程制定和夹具设计的方法以及整个过程中所遇见并需要我们去分析和解决的问题,同时还介绍了如何通过查阅相关手册,结合大学四年所学的课程去确定最合理最正确的加工方式,这当中具体包括了零件工序的确定、工序尺寸和毛坯尺寸的确定、零件的切削用量及所需工时的计算和专用夹具设计时定位和夹紧方式的选择等等。在对零件进行深入分析的同时,还要考虑如何提高生产率、保证加工精度和降低工人的劳动量等。通过大量的分析论证和计算,得到了定位块的工艺路线和其中两道工序的专用夹具设计方法,这将在本文和图纸中具体说明。

关键词:定位块;工艺规程;专用夹具

The mechanical processes of Positioning blockⅡand the special fixture design of the 45 Hole & the 76 Notch

Abstract

Parts processing technology and machinery manufacturing fixture design is a top priority, a good process planning and special fixtures can improve productivity, ensure high precision, save a lot of manpower and financial resources.

Positioning block is a common industry machinery parts, widely used, usually volume manufacturing, therefore, analyze the development process and the positioning blocks were dedicated fixture design is necessary. In the following, mainly introduced the process of positioning block making and fixture design methods and the whole process of encounter and we need to analyze and solve problems, but also describes how access to relevant manuals, binding of the University for four years program to determine the most reasonable and correct processing methods, which were specifically includes the step of cutting the amount of parts is determined, step size, and the size of the blank determination, calculation of parts and man-hours dedicated fixture design and positioning and clamping required Select the like. In-depth analysis of the parts, we must also consider how to improve productivity, to ensure accuracy and reduce the amount of labor workers and the like. Through a lot of analysis and appraisal and calculation to obtain a dedicated fixture design method and process route positioning block in which two processes, which will be specifically described herein and in the drawings.

Key Words: positioning block; mechanical processes; special fixture

零件的作用

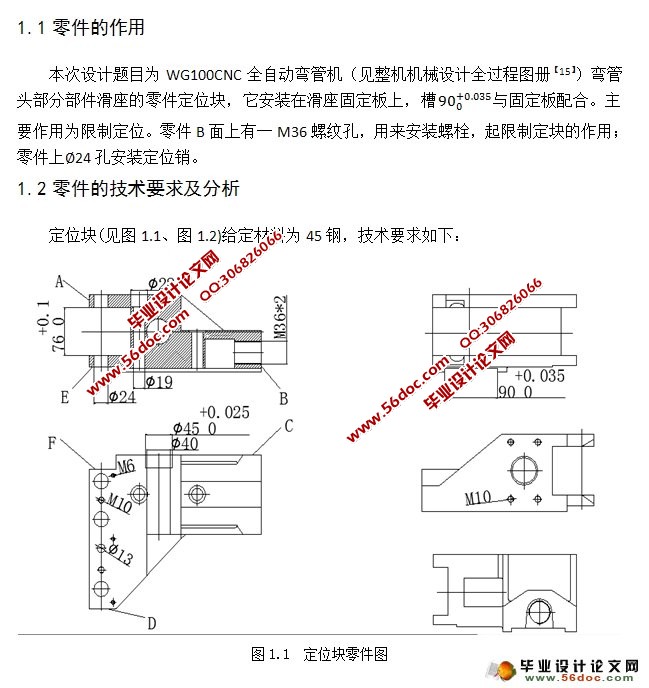

本次设计题目为WG100CNC全自动弯管机(见整机机械设计全过程图册【15】)弯管头部分部件滑座的零件定位块,它安装在滑座固定板上,槽 与固定板配合。主要作用为限制定位。零件B面上有一M36螺纹孔,用来安装螺栓,起限制定块的作用;零件上 24孔安装定位销。

目录

摘 要 I

Abstract II

1 零件的分析 2

1.1零件的作用 2

1.2零件的技术要求及分析 2

1.3零件的工艺分析 3

1.4确定毛坯的制造形式 4

2 工艺规程设计 5

2.1定位基准的选择 5

2.1.1粗基准的选择 5

2.1.2精基准的选择 5

2.2制订工艺路线 5

2.2.1零件表面加工方法的选择 5

2.2.2加工顺序的安排 6

2.2.3机床和工艺装备的选择 7

2.3机械加工余量、工序尺寸与毛坯尺寸的确定 10

2.4确定切削用量及基本工时 13

3 夹具设计 47

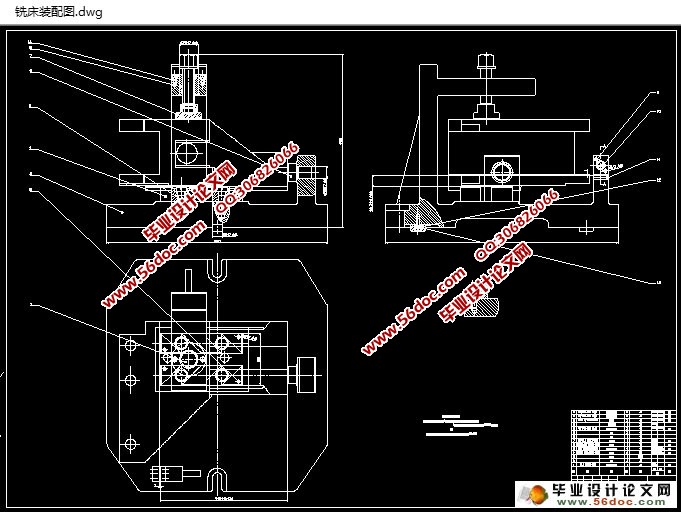

3.1粗铣槽76的专用夹具设计 47

3.1.1原始资料的分析 47

3.1.2定位基准的选择 47

3.1.3定位元件的选择 47

3.1.4对刀装置的选择 47

3.1.5夹具设计分析 48

3.1.6切削力和夹紧力的计算 48

3.1.7定位误差的分析 49

3.1.8夹具设计和操作的说明 51

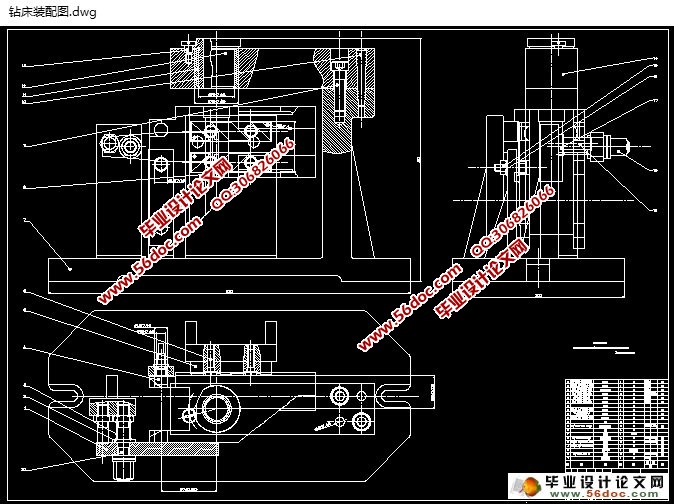

3.2锪钻沉头孔 的专用夹具设计 51

3.2.1原始资料的分析 51

3.2.2定位基准的选择 51

3.2.3定位元件的选择 51

3.2.4钻模板的选择 51

3.2.5钻套的选择 52

3.2.6切削力和夹紧力的计算 52

3.2.7定位误差的分析 53

3.2.8夹具设计和操作的说明 53

结 论 55

参 考 文 献 56

附录1 外文翻译...........................................................................................................58

附录2 译文 66

附录3 机械加工工艺过程卡片...................................................................................75

附录4 机械加工工序卡片...........................................................................................77

致 谢 93