双轴旋耕机的设计(农业机械)(CAD,CAXA零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

双轴旋耕机的设计(CAD,CAXA零件图装配图)(设计说明书13300字,CAD图纸3张,CAXA图纸16张)

摘要

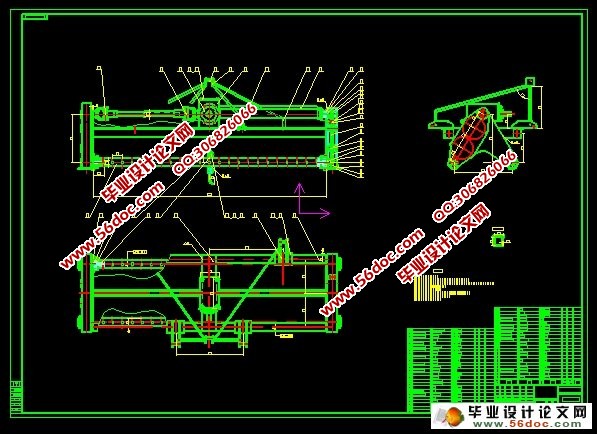

旋耕机是机械化整地的作业的主要农具之一,但目前多数旋耕机翻地以后,还需进行一次耙地作业才能达到农作物生长环境要求。因此,工作效率不高,拖拉机对土壤的二次压实作用也不利于农作物生长。基于国内现有旋耕机技术,提出采用双轴旋耕机技术来解决这个问题。在本次设计中,具体设计了双轴旋耕机总体结构、传动系统、旋耕刀片、四点悬挂装置等。由于幅宽、功率较大,本设计整体采用双侧边齿轮传动,转动平稳、结构基本对称,提高了使用寿命。双轴旋耕机由前后两根旋耕刀刀轴同时工作,一次即可达到耕作要求,从而减少拖拉机对土地的压实次数,提高了工作效率和能源利用率。

关键词

旋耕机;双轴;双侧边传动;设计

The Design of biaxial rotary cultivator

ABSTRACT

Rotary cultivator is one of the main tools in mechanization preparation work. However, the majority of rotary cultivator can’t meet the requirement for crops to grow, the cultivator needs to harrow the soil. Therefore, the working efficiency is not high, the tractor will run on the grand twice, compaction is not conducive to the growth of crops. Based on the domestic rotavator technology, then work out the biaxial rotary cultivator technology to solve this problem. I select the Design of biaxial rotary cultivator as my graduation design topic . In this design program, I Designed the overall structure of the rotary cultivator, transmission system, rotary blade, the four point suspension device , etc . As the width and the power needed are large. By the use of double side gear, the rotation is smooth , the basic structure is symmetric, which can improve the service life. When biaxial rotary cultivator works, the two rotary blade cutter axle rotate at the same time, once to meet the cultivation requirements, which can reduce the times of the tractor compact the grand, improve work efficiency and energy utilization simultaneously.

KEY WORDS

Rotary cultivator;Biaxial;Drive by double side gear;Design

目 录

摘要 II

关键词 II

ABSTRACT III

KEY WORDS III

1 前言 1

1.1课题要求 1

1.2 旋耕机的研究现状与发展趋势 1

1.2.1 国内研究现状 1

1.2.2国外研究现状 2

2 旋耕机的总体设计 2

2.1 旋耕机的总体结构设计 2

2.2 传动方式的选择 2

2.3 限深装置的设计 3

3 旋耕刀工作参数的确定 4

3.1旋耕机的工作原理 4

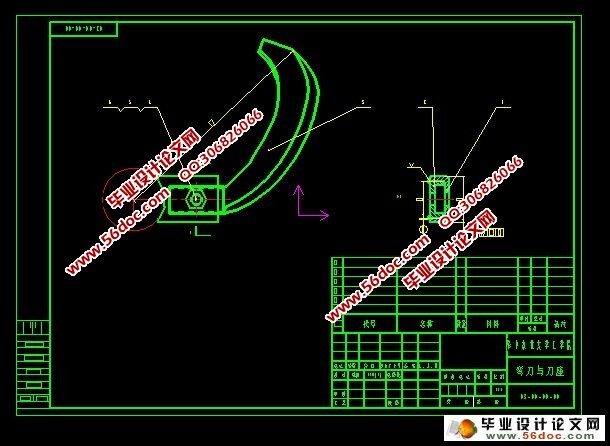

3.2 旋耕刀刀型的选用 4

3.3 旋耕机刀轴速度的确定 6

3.4刀座间距b和弯刀总数Z的确定 7

3.4 弯刀的排列设计 8

4 旋耕机的工作参数 9

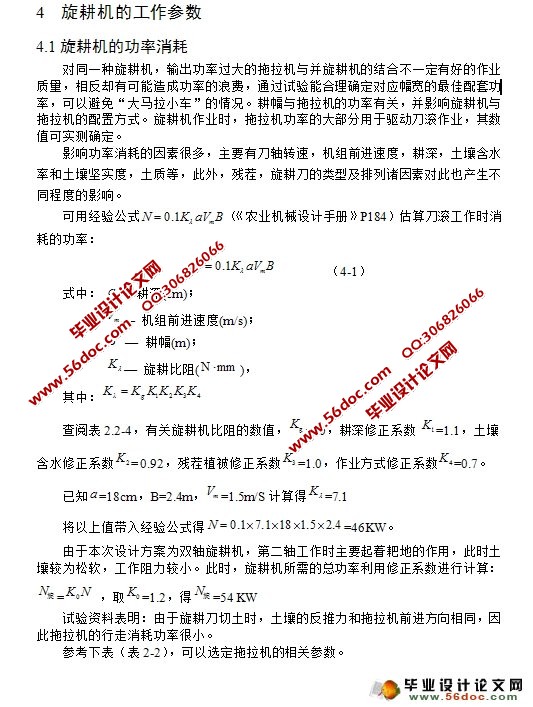

4.1旋耕机的功率消耗 9

4.2 传动参数的确定 10

5侧边齿轮箱的参数设计 10

5.1 齿轮的设计校核 10

5.1.1 齿轮的材料 10

5.1.2圆柱直齿轮的参数设计 11

5.2 齿轮轴系设计校核 14

5.2.1 齿轮轴结构设计 14

5.2.2 齿轮轴上结构配置 18

5.3 刀辊轴的设计计算说明 18

6 设计结论 19

7 设计心得 19

参考文献 21

致谢 23