玉米脱粒机的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

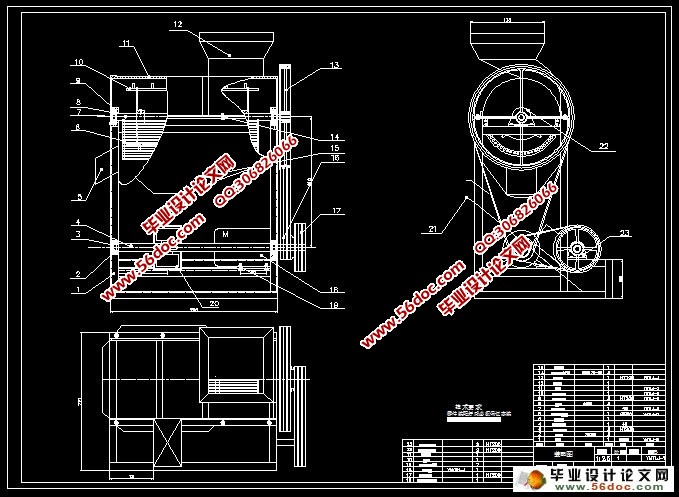

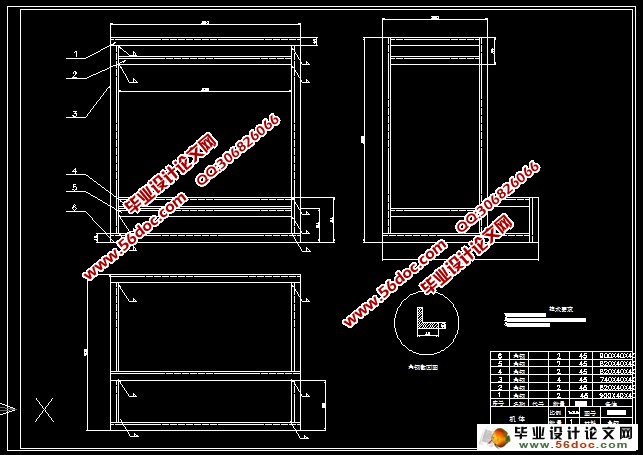

玉米脱粒机的设计(含CAD零件图装配图)(开题报告,中期检查表,论文说明书15000字,CAD图8张)

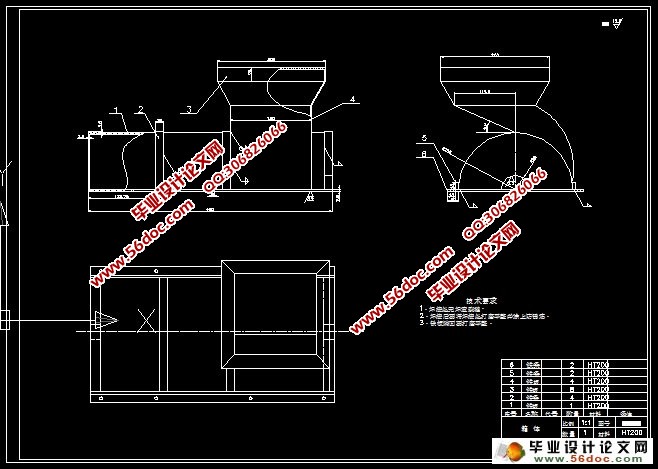

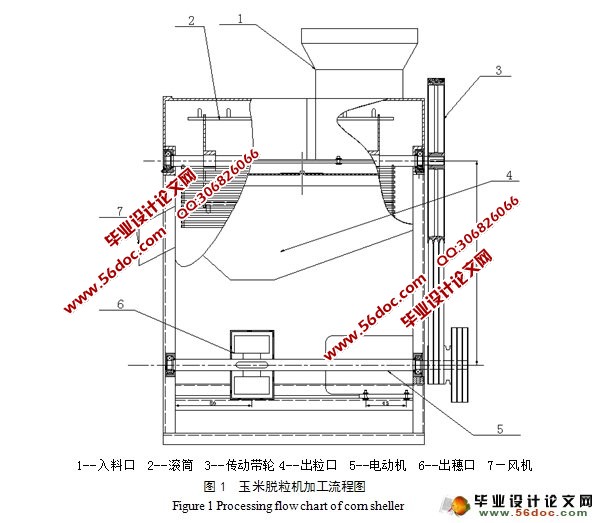

摘 要:本次设计的玉米脱粒机其工作原理为电机经皮带轮传动, 玉米穗通过料斗进入滚筒,在高速回转滚筒的冲击和玉米穗、滚筒、凹板的相互作用下被脱粒。脱下的子粒大部分通过栅板漏下。流出机外。风扇的作用是将夹在子粒中的轻杂带走。与同类产品比,结构紧凑,性能优良,操作轻便,安全可靠,且不占场地,搬运存放方便。破碎率很低,可提高种子发芽率。能大大减轻农民劳动强度,有利于抢赶农时季节,促进农民致富,推动农业的发展。适宜在广大农村推广应用。

关键词: 玉米;脱粒机;全喂入式

The Design of the Corn Thresher

Abstract: The operating principle of the corn thresher in this design is that achieve movement by electrical machinery with driver pulley. Corncobs are putted into the drum through the hopper, in the impact of cylinder which is rotating in high speed and threshed by the fact of cylinder, corncobs , notch board . Most of the extracted seeds leave out through notch-board hole. The partial of seeds smuggling in the ear axis are discharged through the mess mild of the clamps light which are mixed in the seed. Compared to the similar product, this machine is high-quality with the structures in compact, which operates easily, safely, and also not taking up space, transporting conveniently. The percentage of damage is very low, may enhance the seed-germination percentage. It can reduces the farmer labor intensity greatly, advantageous in snatches catches up with the farmer season, promotes the farmer to become rich, impels development agricultural. This is suitable in general countryside promotion application.

Keywords: corn; thresher; organ

目 录

1 前言………………………………………………………………………………………... 1

2 玉米脱粒机机体方案的设计………………………………………………………………. 4

2.1 玉米脱粒机的种类的选择…………………………………………………………4

2.2 脱粒装置的种类的选择……………………………………………………………4

3 喂入口和排出口的选择.………………………………………………………………..… 6

4 脱粒装置的设计.…………………………………………………...………………………. 7

4.1 滚筒类型的设计……………………………………………………………………..…7

4.2 滚筒的直径、转速和长度的设计………………………………………………………7

4.3 钉齿的形状和尺寸的设计……………………………………………………………8

4.4 钉齿的排列……………………………………………………………………………8

4.5 凹板的主要参数设计……………………………………………………………… 10

4.6 滚筒与凹板的工作间隙………………………………………………………………10

4.7 滚筒末端的穗轴排出………………………………………………………………10

5 电动机的选择………………………………………………………………………….… 11

6 清选装置的设计…………………………………………………………………………. 11

6.1 清选装置的功用………………………………………………………………………11

6.2 风机的选择…………………………………………………………………………….11

7 传动部分的设计………………………………………………………………………….. 13

7.1 带轮传动………………………………………………………………………………13

7.2 带轮的材料……………………………………………………………………………13

7.3 滚筒轴的设计计算……………………………………………………………………14

8 轴承的选择与校核……………………………………………………………………….. 19

8.1 轴承选型………………………………………………………………………………19

8.2 轴承的校核……………………………………………………………………………19

9 玉米脱粒机螺栓的选择……………………………………………………………………19

10 键的选择……………………………………………………………………….. ………… 19

11 玉米脱粒机的使用和维护………………………………………………………………... 22

11.1 玉米脱粒机使用的注意事项…………………………………………………………… 22

11.2 玉米脱粒机的维修保养……………………………………………………………….. 22

12 结论 ……………………………………………………………………………………23

参考文献 …………………………………………………………………………………… 25

致谢 …………………………………………………………………………………………. 24