花生收获装置的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

花生收获装置的设计(含CAD零件图装配图)(论文说明书10800字,CAD图10张)

摘 要:花生不仅是优质油料作物,而且是主要的蛋白质源,加工品类多,产业链条长,现已成为中国重要的出口创汇产品和农业结构调整重点发展和扶持的种植品种。在消费结构和出口结构不断调整和优化的双重拉动下,花生生产得到长足发展,并逐渐向主产区相对集中,优势产业带基本形成。但是中国花生生产机械化发展却严重滞后,特别是用工量占生产全过程1/3以上、作业成本占生产总成本50%以上的收获作业,目前主要依靠人工完成,劳动强度大、作业成本高、效率低、损失大、成本高已成为生产发展与产业成长的主要瓶颈,国内对花生机械化收获技术装备的需求日趋迫切。

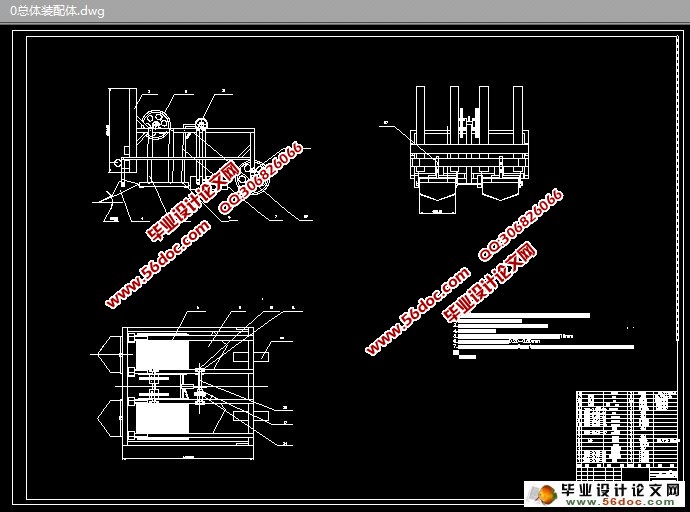

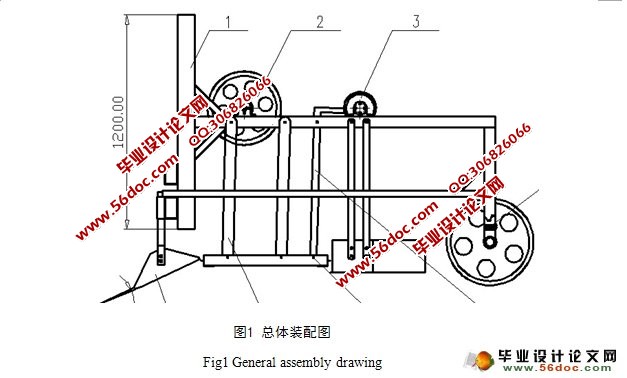

本文通过设计振动筛式花生收获机,以实现小规模生产的机械化生产要求。本论文对振动筛式花生收获机的总体结构、工作原理、技术特点以及关键部件结构与工作参数设计。该设备主要由挖掘铲、振动筛、行走轮、动力传动装置及机架等组成,与11~13.2kw 拖拉机配套使用,一次完成两行花生收获,挖出来的花生蔓被传送到振动筛上,经过振动筛的振动去除挖掘出的花生所带有的泥土,最后通过输送板实现花生蔓一侧倒伏的工作原理。该机具有作业顺畅、运行可靠、清土率高、损失率低等特点,纯生产率达 0.1公顷/小时。

关键词:振动筛;收获机;机械化;花生

Design Of The Peanut Harvesting Machine

Abstract: Peanut is not only a kind of oil-bearing crop with good quality, but also the main resource of protein. It has many machining products and developed industrial chain, and now, it’s becoming an important cultivated variety during agricultural restructuring as well as a significant exporting product in China. The continuous adjustment and optimization of consumption structure and export structure both have stimulated the development of peanut producing, which have also made the peanut producing a competitive industry. However, the mechanization of peanut production in China lags behind. Above all, such harvest activities as the amount of labor used is more than one-third of the total production process, or the cost of harvest accounts for more than 50% of the total cost of production are mainly depending on manual work nowadays. The development of production and the growing of this industry is now facing the choke point, because it has many disadvantages, such as great intensity of labor, high costs, inefficiency, heavy losses, etc. Therefore, there is a pressing need for technical mechanisms of peanut harvesting and producing in our country.

Through designing a vibrating screen peanut harvesting machine, this thesis is trying to achieve the mechanized production of small scale. This thesis concentrates on the designs of gross structure, working principle, technical features, together with the structure and running parameter of critical components. This peanut harvesting machine mainly consists of digging shovel, vibratory screen, road wheel, power transmission, racks and so on. It can be compatible with tractor of 11 to 13.2 W, and can harvest two lines of peanut once a time. The peanut vines will be transmitted to the vibratory screen after being dug out, and then the earth with the vines will be wiped off because of the vibration, and at last, all the peanut vines will be off the same side through a delivery board. Thus, this is how the vibrating screen peanut harvesting machine works. This machine has the advantages of smoothly working, reliable running, efficiently cleansing and low loss rate, etc. with pure productivity of 0.1 hectare per hour.

Keywords: vibrating screen;harvesting machines;mechanization;peanuts

设计依据

(1)作业可靠、减少收获损失

根据相关要求,所设计的花生收获装置应达到的性能指标:

配套动力:11-13.2kw小型四轮拖拉机

生产率:2.5~3.0亩/小时

损失率: 3%

秧果破碎率: 1%

外形尺寸(长x宽x高):1400x1300x1200mm

整机质量:220kg

(2)结构紧凑,降低成本

为便于花生收获装置的推广和使用,考虑到中国现阶段广大花生种植户的消费水平,在保证收获装置作业质量的前提下,进一步简化结构、降低成本,真正使广大农民买得起、用得上。

作业原理

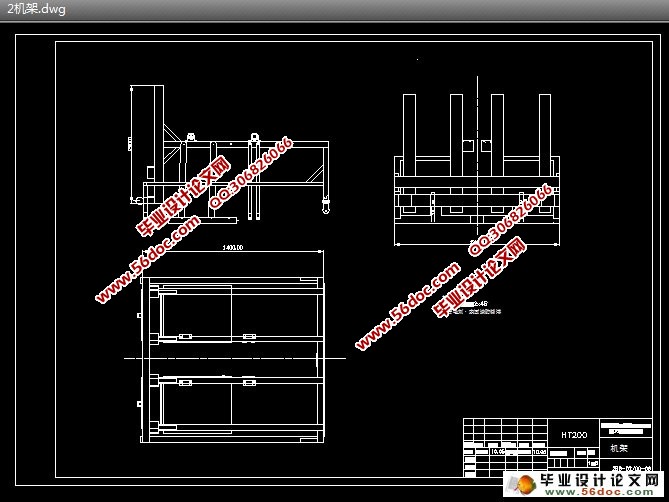

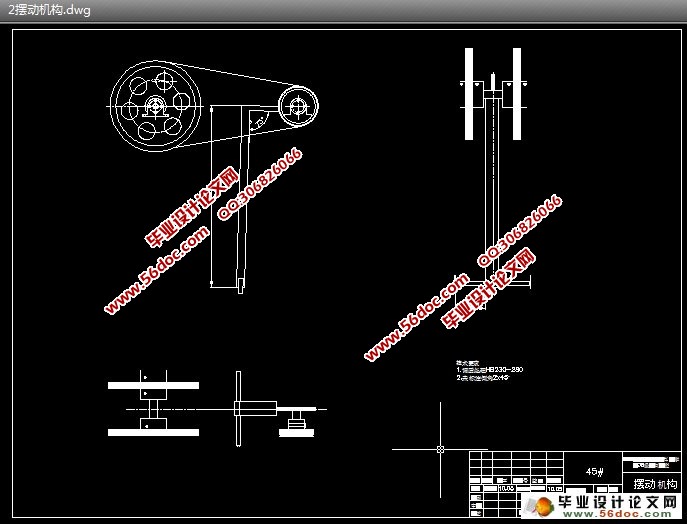

此类振动筛式花生收获机作业时,拖拉机带动收获机具前行,挖掘铲以一定角度铲入土中(挖掘深度通常在100~150mm),将花生主根切断,并将掘起的土壤和花生秧果输送到振动筛上。掘起的土壤和花生秧果进入往复运动的振动筛,将花生和沙土不断地向后振动输送,大部分沙土被振落至筛下,实现清土目的,花生秧果和少部分未去除的沙土随后从振动筛的侧尾端被抛送到已收区,实现成条铺放,待田间晾晒后再进行拣拾作业。行走轮安装在机架上,通过选用不同的定位孔可调节行走轮的安装高度,调节挖掘铲的挖掘深度和入土角。

本机的主要特点:采用侧尾振动筛清土装置,清土效果好、条铺效果好、可靠度高、损失率低。不仅可同时实现清土和输送一体化功能,而且具有震动小、运行平稳可靠、驾乘舒适等特点;通过调节行走轮安装高度,来调整挖掘深度和挖掘铲入土角,操作简单方便;11~13.2 kw 拖拉机即可带动,与现阶段大多数农户拥有的小四轮拖拉机相适应,具有适配动力广,投资少,收效快等特点。

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1绪论…………………………………………………………………………2

1.1研究的目的和意义 ………………………………………………………………2

1.2国内外花生生产现状 ……………………………………………………………3

1.3中国花生的种植方式 ……………………………………………………………4

1.4研究的目标与内容…………………………………………………………………5

2振动筛式花生收获装置的设计原理………………………………………………………5

2.1设计依据 ………………………………………………………………5

2.2设计方案的选择与分析 …………………………………………………………6

2.3总体设计简介 ………………………………………………………………6

2.4作业原理 ………………………………………………………………7

3主要参数确定与关键部件设计……………………………………………………………7

3.1花生收获装置的动力计算 ………………………………………………………7

3.2机架及行走装置的设计 …………………………………………………………8

3.3挖掘装置的设计 ………………………………………………………………9

3.4振动筛装置的设计 ………………………………………………………………14

4结论…………………………………………………………………………20

参考文献 ………………………………………………………………………21

致谢……………………………………………………………………………22