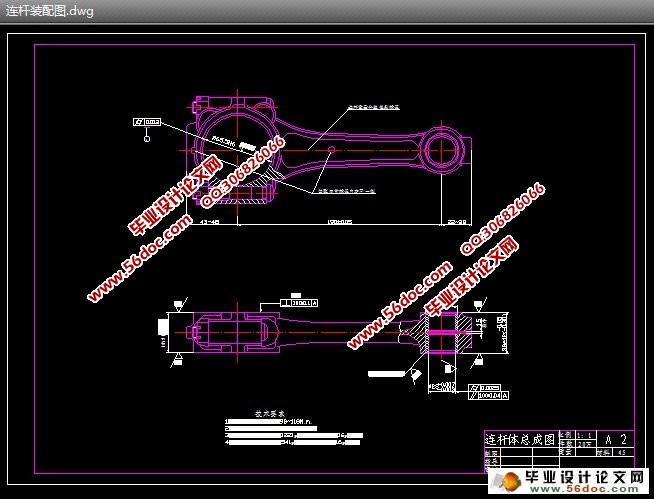

柴油机连杆机加工工艺及夹具设计

无需注册登录,支付后按照提示操作即可获取该资料.

柴油机连杆机加工工艺及夹具设计(任务书,开题报告,毕业论文说明书18000字,CAD图纸6张)

[摘要] 本文主要论述了柴油机连杆的加工工艺及其夹具设计。因为连杆是活塞式发动机和压缩机的主要零件之一,其大头孔与曲轴连接,小头孔通过活塞销与活塞连接,其作用是将活塞的气体压力传送给曲轴,又收曲轴驱动而带动活塞压缩汽缸中的气体。连杆承受的是冲击动载荷,因此要求连杆质量小,强度高。所以在安排工艺过程时,按照“先基准后一般”的加工原则。连杆的主要加工表面为大小头孔和两端面,较重要的加工表面为连杆体和盖的结合面及螺栓孔定位面。 在夹具设计方面也要针对连杆结构特点比较小,设计应时应注意夹具体结构尺寸的大小等,最终就能达到零件的理想要求。

[关键词] 连杆;变形;加工工艺;夹具设计

Machining process and fixture design for connecting rod machine of diesel engine

[Abstract] The diesel connecting rod treating handicraft the main body of a book has been discussed mainly and their grip design. Because of the connecting rod is one of dyadic engine of piston and main compression engine part, whose larger end hole and crank shaft link up , the small head hole links up by the wrist pin and the piston , whose effect is that the piston gas pressure is transmitted to the crank shaft , collect crank shaft gas in driving but setting a piston in motion to compress a cylinder. Being that the pole bears pounds a live load , request connecting rod mass is minor therefore , the intensity is high. Therefore when arranging procedure for, according to "first the criterion queen-like " treating principle. The connecting rod main part processes a surface being that head hole and both ends big or small are weak, more important faying face and bolt hole locating surface being the connecting rod body and cover treating outside. Also should be comparatively small specifically for connecting rod structure characteristic in the field of grip design , design that the size should pay attention to gripping the concrete structure dimension of the season waits, the ideal being therefore likely to reach a part ultimately demands.

[Keywords] Connecting rod, Deformination, Processing technology, Design of clamping device

目 录

任务书 Ⅰ

开题报告 Ⅱ

指导教师审查意见 Ⅲ

评阅教师评语 Ⅳ

答辩会议记录 Ⅴ

中文摘要 Ⅵ

外文摘要 Ⅶ

1 柴油机连杆的加工工艺 1

1.1 柴油机连杆的用途及其特点 1

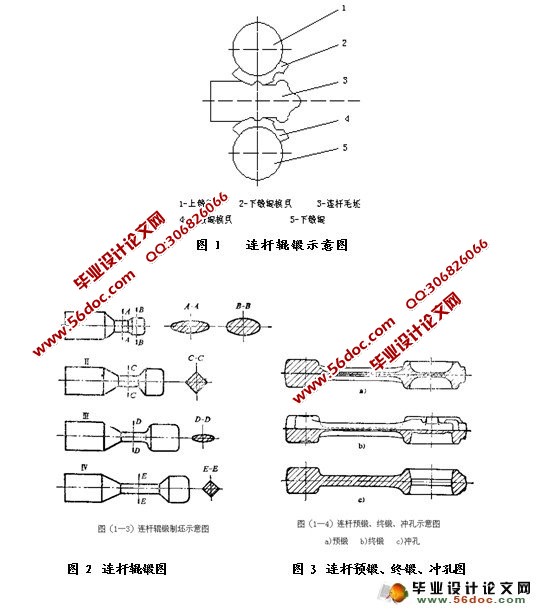

1.2 连杆的的材料及毛坯制造 2

1.3 连杆的加工工艺过程 4

1.4 连杆的加工工艺过程分析 5

1.4.1 定位基准的选择 5

1.4.2 加工顺序的安排 6

1.4.3 确定合理的夹紧方法 8

1.4.4 连杆主要面的加工方法 9

1.4.5 连杆主要孔的加工方法 9

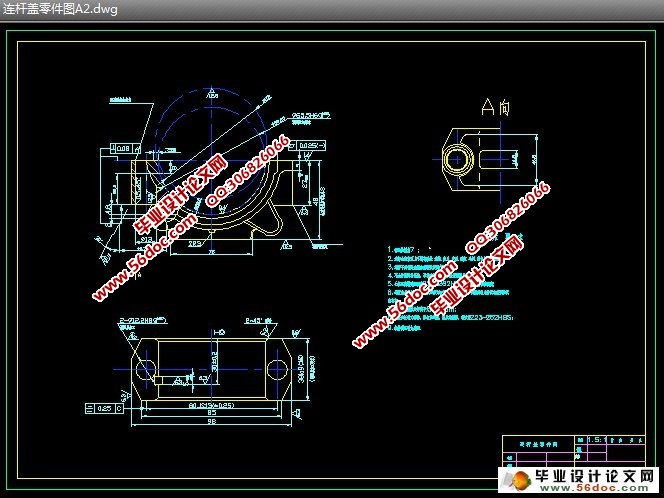

1.4.6 连杆体与连杆盖的铣开工序 10

1.5 夹具使用 10

1.6 工序具体内容的确定 10

1.6.1 切削加工影响表面粗糙度的因素 11

1.6.2 磨削加工影响表面粗糙的因素 12

1.6.3 具体加工工序 13

1.7 重要工序的说明 16

1.7.1 粗磨连杆两端面 16

1.7.2 钻小头孔 16

1.7.3 拉连杆两侧面及凸台面 16

1.7.4 铣断 17

1.7.5 镗连杆小头杆 17

1.7.6 珩磨连杆大头孔 18

1.8 连杆的检验 18

1.8.1 观察外表缺陷及目测表面粗糙度 18

1.8.2 检查主要表面的尺寸精度 18

1.8.3 检验主要表面的位置精度 19

1.8.4 连杆螺钉孔与结合面垂直度的检验 19

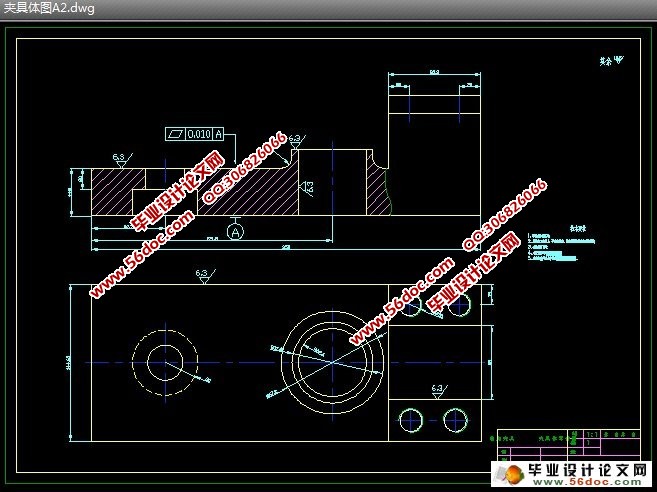

2 机床夹具设计 19

2.1 夹具的问题注意 19

2.2 夹具设计的基本要求 20

2.2.1 夹具设计的基本要求 20

2.2.2 机床夹具 20

2.3 夹具设计方案的确定 21

2.4 夹具的整体设计 22

2.4.1 夹具的基本结构和工作原理 22

2.4.2 定位元件的确定 23

2.4.3 夹紧弹簧的确定 23

3 刀具的选择 23

4 总结 25

参考文献 27

致谢 28