CA6140车床进给系统的数控改造

无需注册登录,支付后按照提示操作即可获取该资料.

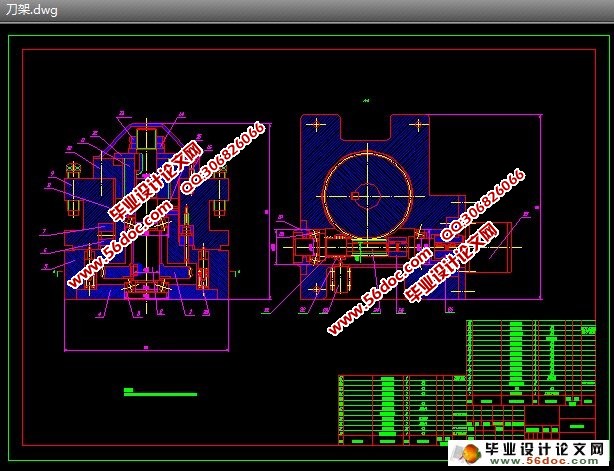

CA6140车床进给系统的数控改造(论文说明书31000字,外文翻译,CAD图6张)

摘 要

本文介绍了普通数控机床中CA6140车床进给系统的设计改造过程,主要为机械元件的设计,包括滚珠丝杠、轴承、步进电机、和齿轮传动比的计算、选择与应用。针对现有常规CA6140普通车床的缺点提出数控改装方案,提高加工精度和扩大机床使用范围,并提高生产率。改造后的机车,主运动实现自动变速,纵向、横向进给系统进行数控控制,并要求达到纵向最小运动单位为0.01mm每脉冲,横向最小运动单位0.005mm每脉冲,刀架要是自动控制的自动转位刀架,要能自动切削螺纹。

关键词:齿轮;滚珠丝杠;步进电机;

Abstract

This article concise language had the stress in the introduction ordinary numerical control engine bed the economy numerical control tool machine entered for the design process, mainly for mechanical part design, including ball bearing guide screw, bearing, stepper motor , and synchronized tooth profile belt computation, choice and application. To remedy the defects of ordinary lather CA6140, a design of data processing system and its single chip microcomputer system program is put forward to raise the processing precision and extend the machine’s usage, and to improve production rate. so the Motorcycle been reformed, the lord exercises realize to change speed automatically. lengthways, horizontal enter to proceed to system the number controls the control, and request to attain lengthways minimum sport unit as 0.01 mm/ pulse, horizontal minimum sport unit as 0.005 mm/ pulse, knife must be the automatic control a knife which is turning automatically, and it is able to slice the thread automatically. This paper presents the process of designing numerical control reform, and explicitly introduces the design of mechanical and numerical control system reforms.

Key word: numerical control; ball bearing guide screw; stepper motor; reform design

设计参数

CA6140 车床数控改造技术参数

最大工件直径 400 mm

最大工件长度 1500 mm

溜板及刀架重力

纵向( Z 轴 ) 800N ; 横向( X轴 ) 600N

刀架快速移动速度: 纵向2.4m/min;横向1.2m/min

最大进给速度: 纵向0.6m/min;横向0.3m/min

定位精度 mm

主电机功率 7.5 kw

启动加速时间 30 ms