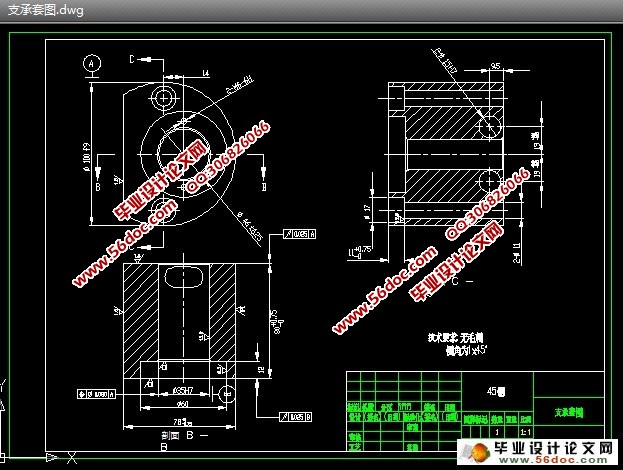

零件(支承套)数控加工工艺分析及工艺装备设计(含加工程序)

无需注册登录,支付后按照提示操作即可获取该资料.

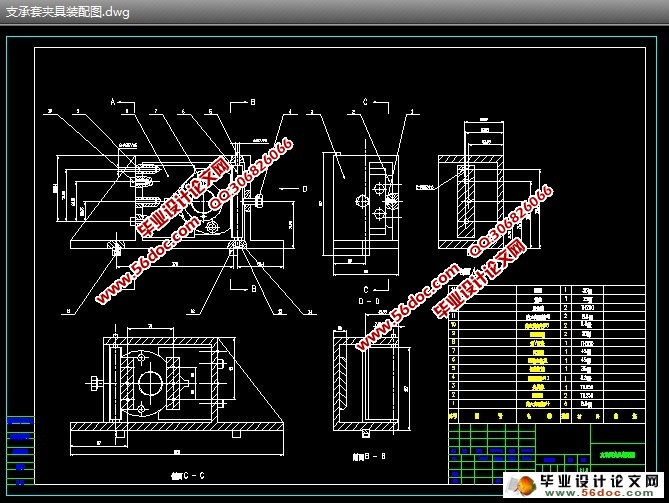

零件(支承套)数控加工工艺分析及工艺装备设计(含加工程序)(任务书开题报告,说明书19000字,支承套数控加工程序,CAD图2张)

摘 要

高效率、高精度加工是数控机床加工最主要特点之一。利用数控机床加工,其产品加工的质量一致性好,加工精度和效率均比普通机床高出很多,尤其在轮廓不规则、复杂的曲线或曲面、多工艺复合化加工和高精度要求的产品加工时,其优点是传统机床所无法比拟的。本课题对异性体、复杂的曲线、多工艺复合化加工进行探索,设计出三种切实可行的工艺流程及工艺装备。在产品的加工过程中,工件在夹具内的定位和夹紧显得特别重要。须根据六点定位对产品进行合理的定位,欠定位、完全定位还是过定位都须根据实际的生产过程决定。夹具是涵盖了从加工到组装的几乎所有操作过程的一种装夹设备。由于大量的加工操作需要装夹,夹具设计在制造系统中就变得非常重要,它直接影响加工质量,生产率和制造成本。本文通过分析支承套的结构特点和加工要求,制定了一套较合理的夹具设计,从而为保证该零件的加工精度将提供一种经济实用的工艺装备,具有一定的实用价值。通过对各种定位夹紧装置的分析比较,选择并组合了一套既能够满足加工要求的,又比较简洁的装置,并对各工步进行数控编程。

关键词:数控加工,工艺流程,工艺装备,夹具设计

Components Numerical Control Processing Craft Analysis

and Craft Equipment Design

ABSTRACT

The high efficiency, the precision work are one of numerical control engine bed processing most main characteristics. Using the numerical control engine bed processing, its product processing quality uniformity is good, the processing precision and the efficiency outdo compared to the ordinary engine bed very much, especially when outline not rule, complex curve or curved surface, multi-craft recombine processing and high accuracy request product processing, its merit is the traditional engine bed is unable to compare. This topic to the opposite sex body, the complex curve, the multi-craft recombine processing carries on the exploration, designs three practical and feasible technical processes and the craft equipment. In the product processing process, the work piece appears in jig localization and the clamp specially importantly. Must act according to six localizations to carry on the reasonable localization to the product, owes the localization, locates completely crosses the localization all to have to act according to the actual production process decision. The jig covered from has processed clamps the equipment to the assembly nearly all operating process one kind of attire. Because the massive processing operation needs to install clamps, the jig design changes can it be that the constant weight in the manufacture system to want, it affects the processing quality directly, the productivity and the production cost. This article through the analysis support components, the air compressor snifting valve lid as well as the supporting the unique feature and the processing request which wraps, has formulated a set of reasonable jig design, thus for guaranteed this components the processing precision will provide one economical practical craft equipment, will have certain practical value. Through to each kind of localization clamp analysis comparison, chose and combines a set both to be able to satisfy the processing request, and the quite succinct installment, and carried on the numerical control programming to each step working procedure.

Key word: numerical control processing, technical process, craft equipment, jig design

在本次毕业设计中,要完成的是分析支承套、支架零件、空压机吸气阀盖头三个零件的加工工艺并为它们各设计一套工艺装备,三个零件都属于大批量生产三个零件,但所要加工的内容不同,零件本身的形状复杂程度也不同,所以要设计出合适每个零件的最简洁的专用夹具并且制定加工工序。支承套使用专用框式夹具,采用V型块和支撑板定位,翻页板螺钉夹紧;支架零件采用圆柱销,菱形销一面两销孔定位,并设计了专门装夹零件的过渡真空平台,以压板螺栓辅助定位;空压机吸气阀盖头使用两道工序,均采用一面两销孔定位,压板螺栓夹紧,只不过两次装夹时压板位置不同。在制订工艺流程和选择工艺元件时参考了一些相关书籍和机械设计手册,并比较了多种工艺方案最终决定了各零件的最终加工工艺流程。

目 录

摘要………………………………………………………………………… 1

ABSTRACT…………………………………………………………………… 2

0 引言……………………………………………………………………… 4

1 数控加工技术概述……………………………………………………… 5

1.1 数控加工技术的发展………………………………………………… 5

1.2 数控加工工艺的特点………………………………………………… 6

1.3 数控机床与普通机床相比具有的优越性…………………………… 7

2 夹具设计过程…………………………………………………………… 9

2.1 设计夹具的目的……………………………………………………… 9

2.2 夹具的分类………………………………………………………… 10

2.3 专用夹具的组成…………………………………………………… 12

2.4 典型的定位元件…………………………………………………… 13

2.5 夹具中的夹紧机构………………………………………………… 16

2.6 夹具的发展趋势…………………………………………………… 17

3 机械加工工艺规程的制定…………………………………………… 19

3.1 机械加工工艺规程的作用………………………………………… 20

3.2 机械加工工艺规程的制定程序…………………………………… 20

3.3 毛坯的选择………………………………………………………… 21

3.4 定位基准的选择…………………………………………………… 22

3.5 零件表面加工方法的选择………………………………………… 24

3.6 加工顺序的安排…………………………………………………… 25

4.1 支承套……………………………………………………………… 27

4.1.1 零件加工工艺分析……………………………………………… 27

4.1.2 毛坯的选择……………………………………………………… 28

4.1.3 数控加工工艺分析及工序设计………………………………… 31

4.1.4夹具设计………………………………………………………… 34

5 结论…………………………………………………………………… 36

6 致谢…………………………………………………………………… 37

参考文献………………………………………………………………… 38

附录1…………………………………………………………………… 39