轴类零件数控车削加工工艺及程序编制(CAD,CAXA)

无需注册登录,支付后按照提示操作即可获取该资料.

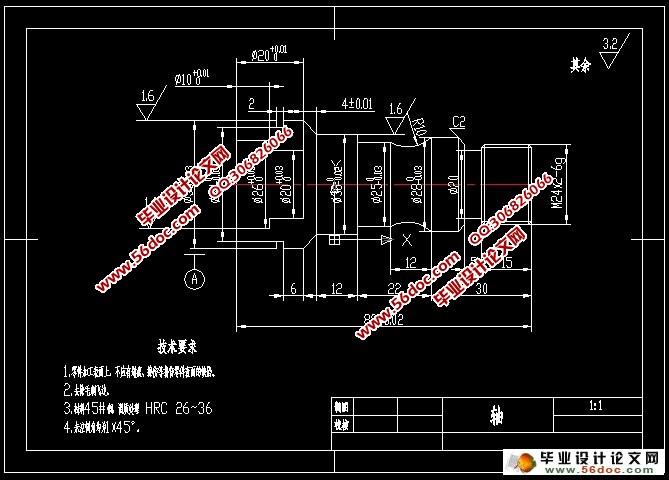

轴类零件数控车削加工工艺及程序编制(CAD,CAXA)(设计说明书7600字,CAD图1张,CAXA图1张)

摘 要

本文主要针对回转轴类零件工艺进行数控加工工行分析,它意义深重,本文将对它进行讲述。零件的工艺设计内容主要有零件加工工艺过程设计、加工工序设计、程序设计,以及机床、刀具、夹具的选择等等。重点分析了零件的数控加工工艺过和和所采用的程序结构,例如如何合理运用G76,G73,G70等常用复合循环指令进行零件的粗加工、精加工程序的编制。此外,在加工设计过程中也展开了相应的讨论,并且得出了此类回转型零件的一般加工步骤。

课题贯穿本专业所学到的议论知识与实践操作技术,从分析设计到计算、操作得到成品,同时本次选题提供了自主学习,自主选择,自主完成的机会。毕业设计有实践性,综合性,探索性,应用性等特点,本次选题的目的是数控专业教学体系中构成数控技术专业知识及专业技能的重要组成部分,是运用数控机床实际操作的一次综合练习。

关键词:尺寸精度 工艺设计 程序编制

Abstract

In this paper, rotating shaft parts for CNC machining technology of the bank analysis, it profound meaning, this article will be about it. Part of the process design the content of main machining process planning, machining process design, process design, and machine tools, tools, fixtures, etc. choices. Analyzed Machining of parts and used over and the program structure, such as the reasonable use of G71, G73, G70, G92 and other commonly used parts combined-cycle instructions roughing, finishing the program design. In addition, the design process has started processing the corresponding discussion, and come back transformation of such parts of the general processing steps.

Topics learned throughout the discussion of this professional knowledge and practical operating techniques, from analysis and design to the calculation, the operation that finished at the same time this provides a self-learning topics, self-selection, self-completion opportunities. Graduation design practical, comprehensive, exploration, and applicability, this topics purpose constitute the teaching system of numerical control CNC technical expertise and professional skills important part is to use the actual operation of a CNC machine tool Exercises.

Key words: dimensional accuracy of process design programming

目 录

摘 要 3

Abstract 4

1 绪论 5

1.1课题的意义 5

1.2数控机床的发展趋势 6

2零件图样分析 6

2.1结构工艺性 6

2.2精度分析 7

3工序的划分 7

4螺纹加工工艺分析 8

4.1螺纹的基础知识 8

4.2螺纹的加工方法 9

5刀具的选择 10

5.1刀具的选择原则 10

5.2刀具卡片 10

6切削用量的选择 10

6.1切削用量的选择原则 10

6.2选择时的注意事项 11

7程序设计及调试 12

7.1常用编程指令 12

7.2加工程序清单 13

7.3程序调试 15

8设计总结 16

致谢 17

参考文献 18

附录1 机械加工工艺过程卡片 19

附录2 数控加工工序卡片 20

附录2.1 数控加工工序卡片 21