耳机塑料模具设计(CAD,Proe三维)

无需注册登录,支付后按照提示操作即可获取该资料.

耳机塑料模具设计(CAD,Proe三维)(任务书,开题报告,中期检查表,外文翻译,设计说明书19000字,cad图纸5张,Proe三维建模)

摘要

近年来,工程塑料以其优异的性能获得了越来越广泛的应用。而注塑模具是

其中发展较快的种类,在人们生活的各个领域都能够见到塑料制品。因此,研究

注塑模具对了解塑料产品的生产过程和提高产品质量有很大意义。

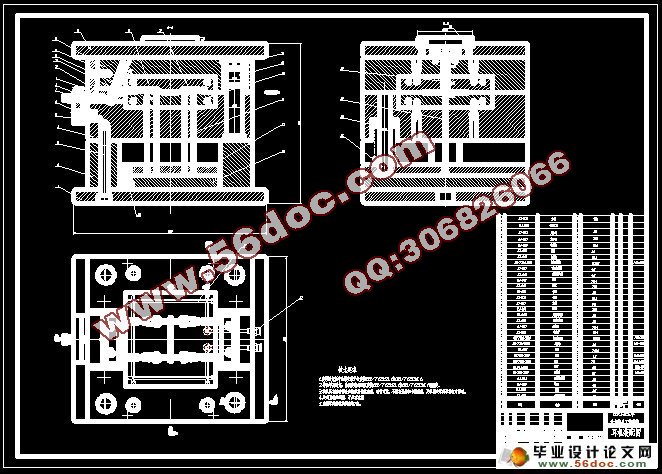

本设计分析了耳机的结构,提出了模具设计的关键点,设计了模具的整体结

构。根据塑件分型面的位置,设计了斜导柱外侧抽芯结构,零件采用了单分型面

的点浇口,提高了零件的外面质量。通过对塑件进行工艺的分析及其结构分析,

从产品结构工艺性,具体模具结构出发,对模具的浇注系统、模具成型部分的结

构、顶出系统、注射机的选择及有关参数的校核都有详细的设计。该模具一模四

腔,采用顶针顶出结构。经过生产验证,该模具结构合理,动作可靠。

关键词:耳机;塑料模具;注射机

The Plastic Mold Design of headphone

Abstract

Inrecent years,more widely plastics for its excellent performance. The injection

mold is a fast-growing type of plastic products in all areas of life people are able to

see. Therefore, the study of injection mold has a great understanding of the production

process of plastic products and improve product quality.

The design and analysis of the structure of the headphones, the critical point of

the mold design, the overall structure of the design of the mold. According to the

position of the parting surface of plastic parts, design Bevel Pillar the outside

pumping core structure, the parts are made of a single sub-surface point gate, and

improve the quality of the parts outside. Process from the product structure, process

analysis and structural analysis of plastic parts, the specific mold structure departure

check of the selection and the parameters of the casting mold system, the mold

forming part of the structure, ejection system, injection machine has a detailed design.

The mold cavity of a mold, ejector structure. The mold production-proven, reasonable

structure, reliable action.

Keyword:headphone;Plastic mold;Injection machine

目录

1绪论...........................................................................................................................1

1.1塑料模具概况......................................................................................................1

1.2国内外发展状况.................................................................................................1

1.2.1国内发展状况..............................................................................................1

1.2.2国外发展状况..............................................................................................2

1.2.3中国与国外先进技术的差距.......................................................................2

1.3塑料模具发展走势..............................................................................................2

2塑件成型工艺的可行性分析 ........................................................................4

2.1功能设计..............................................................................................................4

2.2塑件分析..............................................................................................................4

2.3材料的选择..........................................................................................................4

2.4成型工艺分析......................................................................................................5

2.4.1成型工艺分析主要包括:...........................................................................5

2.5塑件的生产批量..................................................................................................7

3拟定模具结构和注塑机的选择....................................................................8

3.1估算塑件体积......................................................................................................8

3.2由锁模力选定注射机..........................................................................................8

3.3注塑机的校核......................................................................................................9

3.3.1最大注塑量的校核.......................................................................................9

3.3.2塑化能力的校核...........................................................................................9

3.3.3锁模力校核...................................................................................................9

3.3.4模具厚度校核.............................................................................................10

3.3.5开模行程校核.............................................................................................10

3.3.6喷嘴尺寸校核............................................................................................10

4浇注系统设计 ..................................................................................................12

4.1浇注系统............................................................................................................12

4.2主流道设计........................................................................................................12

4.3冷料穴设计........................................................................................................13

4.4分流道设计........................................................................................................13

4.4.1分流道的布置形式.....................................................................................13

4.5浇口设计............................................................................................................14

4.6剪切速率的校核................................................................................................15

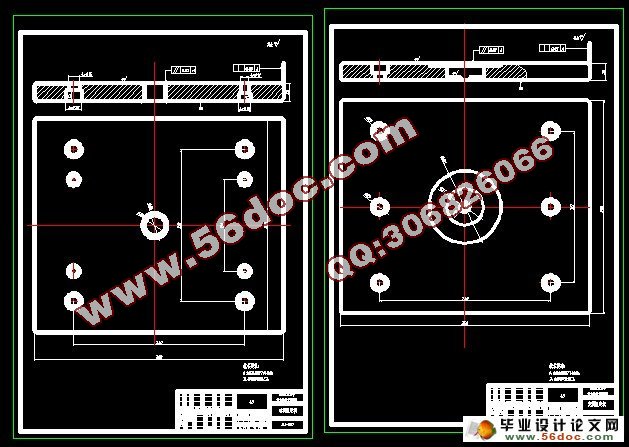

5成型零件设计 ..................................................................................................17

5.1分型面的设计....................................................................................................17

5.1.1分型面的分类及选择原则.........................................................................17

5.2型腔数目的确定................................................................................................17

5.3成型零件结构设计............................................................................................18

5.3.1成型零件具备的性能.................................................................................18

5.3.2型腔壁厚和底版厚度计算.........................................................................18

5.4模架的选用........................................................................................................20

5.4.1模仁尺寸的确定.......................................................................................200

6导向机构设计......................................................................................................22

6.1导向机构的作用和设计原则............................................................................22

6.1.1导向机构的作用.........................................................................................22

6.1.2导向机构的设计原则:.............................................................................22

6.2导柱、导套的设计............................................................................................23

6.2.1导柱的设计.................................................................................................23

7脱模机构的设计..............................................................................................24

7.1脱模机构的设计原则......................................................................................244

7.2顶出机构的确定................................................................................................24

7.2脱模力的计算....................................................................................................25

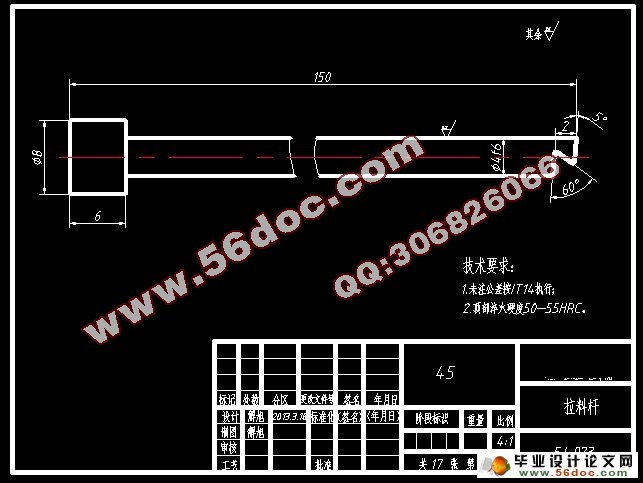

7.3推杆脱模机构....................................................................................................26

8抽芯机构设计 ..................................................................................................28

8.1抽芯机构的概述...............................................................................................28

8.2抽芯机构的设计................................................................................................28

8.3脱模机构运动分析、强度设计........................................................................29

9温度调节系统设计.............................................................................................32

9.1模具冷却系统的结构........................................................................................32

10模具装配图及工作过程.................................................................................34

10.1模具装配二维图............................................................................................344

10.2模具装配图三维爆炸图..................................................................................34

11模具可行性分析 ...............................................................................................36

11.1本模具的特点..................................................................................................36

11.2市场效益及经济效益分析..............................................................................36

12结论 ......................................................................................................................37

致谢 ............................................................................................................................38

参考文献...................................................................................................................39

毕业设计(论文)知识产权声明 ....................................................................40

毕业设计(论文)独创性声明.........................................................................41