汽车前桥支架座冲压工艺及模具设计

无需注册登录,支付后按照提示操作即可获取该资料.

汽车前桥支架座冲压工艺及模具设计(选题审批表,任务书,开题报告,中期检查表,论文说明书12600字,CAD图11张)

摘要:模具设计是机械专业一个最重要的教学环节,是一门实践性很强的学科,是我们对所学知识的综合运用,通过对专业知识的综合运用,使学生对模具从设计到制造的过程有个基本上的了解,为以后的工作及进一步学习深造打下了坚实的基础

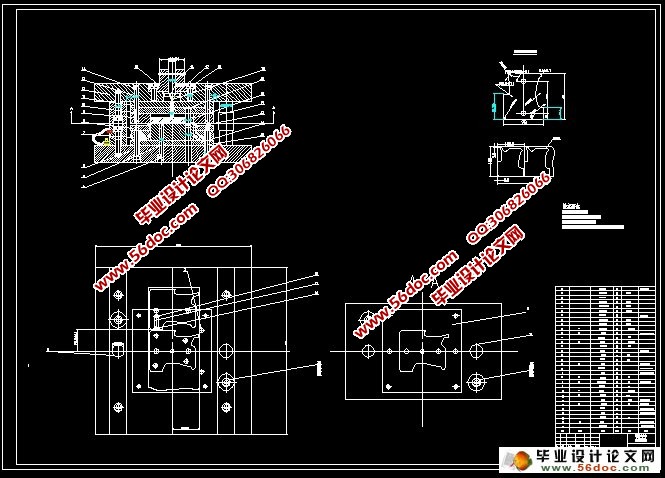

本文介绍的模具实例结构简单实用,使用方便可靠,首先根据工件图算工件的展开尺寸,在根据展开尺寸算该零件的压力中心,材料利用率,画排样图。根据零件的几何形状要求和尺寸的分析,采用复合模冲压,这样有利于提高生产效率,模具设计和制造也相对于简单。当所有的参数计算完后,对磨具的装配方案,对主要零件的设计和装配要求技术要求都进行了分析在设计过程中除了设计说明书外,还包括模具的装配图,非标准零件的零件图,工件的加工工艺卡片,工艺规程卡片,非标准零件的加工工艺过程卡片。

关键词: 凹凸模设计、模具结构设计、冲压工艺

Stamping Process and Die Design of Bracket Seat of Front Axle in the Automobile

Abstract: Mold design is one of the most important mechanical professional teaching link, is a door practice-needed curriculum, is we to the knowledge of the comprehensive utilization, through the comprehensive use of professional knowledge, enables the student to the mold from design to manufacturing process have a basically understanding for the future work and further study to lay a solid foundation .

This paper introduces the mould structure is simple, practical, and use examples convenient and reliable, first of all, according to the workpiece development size of workpiece figure is in development size, according to calculate the parts of pressure center, material utilization, painting the strip layout diagram. According to the geometrical shape parts requirements and size analysis, using composite modulus stamping, it helps improve the production efficiency, mould design and manufacture also relative to the simple. When all the parameters are calculated to mold after assembly scheme of main parts, the design and assembly required technical requirements are analyzed in the design process in addition to the design specification outside, still include mould assembly drawings, non-standard parts graph, the processing technology of the workpiece, process planning CARDS, CARDS non-standard parts processing process card.

Keywords: Punching blanking mold, Bump mold design, Stamping process

目 录

摘要……………………………………………………………………………1

关键词…………………………………………………………………………1

1 前言…………………………………………………………………………1

2 课题概述……………………………………………………………………3

3 冲模设计……………………………………………………………………3

3.1 工艺分析 …………………………………………………………………4

3.2工艺方案的分析与确定…………………………………………………4

3.3排样图设计与材料利用率计算………………………………………………5

3.4计算冲压力 …………………………………………………………………7

3.5初选压力机…………………………………………………………………9

3.6计算压力中心……………………………………………………………………9

3.7卸料橡胶的设计…………………………………………………………………11

4 计算凸凹模刃口尺寸及公差 …………………………………………………………11

4.1 凹模各孔口位置尺寸……………………………………………………………11

4.2 卸料板各孔位置尺寸……………………………………………………………12

4.3 凸凹模各孔位置…………………………………………………………………12

4.4 间隙的选择………………………………………………………………………13

4.5 落料凹模刃口尺寸,按磨损情况分类计算……………………………………13

4.6 冲孔凸模刃口尺寸,按磨损情况分类计算……………………………………13

5 模具总体设计………………………………………………………………………14

5.1模具类型的选择…………………………………………………………………14

5.2定位方式的选择…………………………………………………………………14

5.3卸料、出件方式的选择…………………………………………………………14

5.4导向方式的选择……………………………………………………………14

5.5模架的选择…………………………………………………………………14

6 模具总装配图 …………………………………………………………………………15

7 模具零部件的设计 ……………………………………………………………………15

7.1 凹模设计…………………………………………………………………………15

7.2 冲裁凸模设计……………………………………………………………………15

7.3 其他主要模具零部件的选用……………………………………………………16

8 模具零件的加工工艺 …………………………………………………………………17

8.1 上模板的加工工艺规程编制……………………………………………………17

8.2 凹模的加工工艺规程编制………………………………………………………18

8.3 其他零件的加工…………………………………………………………………20

9 模具的整体装配与试模 ………………………………………………………………23

10 结论 ……………………………………………………………………………………24

参考文献 ………………………………………………………………………25

致谢……………………………………………………………………………25