固定片冲孔落料复合模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

固定片冲孔落料复合模具设计(含CAD零件图装配图)(文献综述,设计说明书13000字,CAD图11张,实习报告)

The fixed plate punching Blanking Compound Die Design

摘 要

中国科技的发展,冲压模具制造技术功不可没,在金属和非金属的塑性加工的过程中,模具是一种必不可少的工艺装备。早在二十世纪中,美国、日本等工业发达国家,集合了人才和资金开发应用冷冲压技术,将模具作为一个统一的产业来发展,因而取得了显著的效果。经过多年的耕耘,在模具的标准化、模具的寿命、效率,加工精度和生产周期等方面形成了新理论和方法,进一步实现快速制模,开辟了新的技术空间,打下了坚实的基础。

虽然中国对制造技术起步比较晚,但在过去十几年中,也相对取得了较大的进步,模具制造技术正在大批量的生产中,在发达国家的的制造理论中,取其精华,去其糟粕,综合他们的理论,形成了自己的方法,打造了属于自己的理论规模,应用在各行各业如汽车零件,飞机,各种大规模的工厂,家用电器等等。

我国的冲压技术虽然有了较大的提高,但是与发达国家比相形见拙,与他们相比仍有一定的差距,主要表现在冲压基础理论与成型工艺的落后,模具的标准化程度低;模具的设计方法和工艺设备的落后;我国模具的专业化水平与发达国家相比在寿命上,加工精度和效率等方面的作对比,还是有一定的差距;所以为了改变这种被动状态,应尽快适应社会主义工业化建设对冲压生产水平提高的需求,应大范围的做模具基础和对模具的研发和推过,是至关重要的。

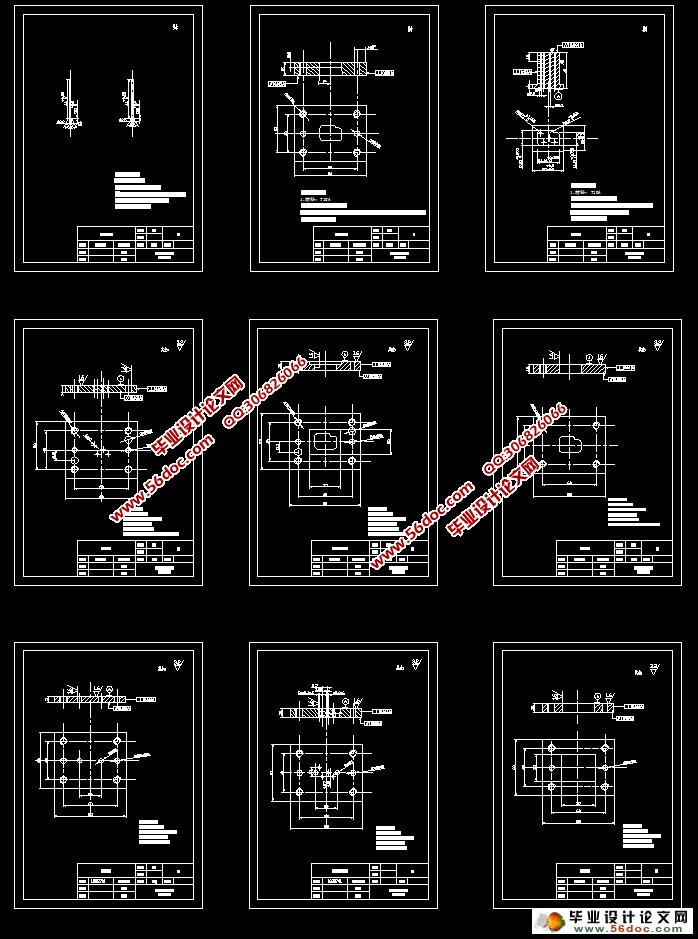

我们本次设计的模具是冲压复合模,进行模具设计时,主要分为以下几步:一,通过翻阅文献和课本相关资料,了解模具的基本结构,有哪些重要的模具组成部件。二,对需要加工的工件进行工艺分析,分析工件的各种特性和加工要求,确定相应的工艺方案。三,对模具进行总体的结构设计,分别确定模具类型、模具的卸料方式、对弓箭的导向方式与定位方式的选择确定。四,计算模具一系列的参数,包括冲裁力、弯曲力等,并确定压力机的型号。五,是模具设计的重要部分,主要零部件的设计,包括冲孔凹凸模、弯曲凹凸模、模架、定位块、卸料杆等各种设计。六,是模具的总装配,根据设计好的模具零部件进行装配,通过CAD画出装配图,完成整套设计。

关键词: 冷冲压; 模具; 冲裁件

ABSTRACT

Technology standardization technology in the development of science and technology of China, stamping die manufacturing technology, metal and non metal plastic processing and mold is a kind of essential equipment. Early in the twentieth century, the United States, Japan and other industrialized countries, a collection of personnel and funds to develop cold stamping technology, will die as a unified industry to develop, and achieved remarkable results. After years of cultivation, in the mold, the mold life, efficiency, machining precision and production cycle, form the new theory and methods, and further achieve rapid manufacturing mold, opened up a new space, and lay a solid foundation.

Although China of manufacturing technology started relatively late, but in the past decade, relatively made great progress, die manufacturing technology is large quantities of production, in developed countries the manufacturing theory, take the essence to the dregs, their theoretical synthesis, formation method of their own, unique, though not mature, but the initial scale, is also widely used, for example, in automobiles, household appliances, electronic products, aerospace activities and daily activities can be seen everywhere in the cold stamping products.

Stamping technology in our country, although there have been greatly improved, but with the developed countries than dwarfs, and they compared still a certain gap, mainly in stamping theoretical basis and forming process of backward, the low degree of standardization of the mold; mold design method and process equipment backward, low level of specialization of mold and the mold in the life, efficiency, machining precision and production cycle and developed countries compared to the mold gap is relatively large; so in order to change the passive status should be as soon as possible to adapt to socialist industrialization construction hedge pressure to improve the level of production demand, should be generous to do based on the mould and die on the R & D and push And it is very important.

Determine the orientation and characteristic of each mold our design of die stamping compound die, mold design, mainly divided into the following steps: first, through literature and books related information, to understand the mold basic structure, what are the important components. Second, to processing the workpiece craft analysis, analysis of the workpiece processing requirements, determine the corresponding process scheme. Third, to mold the overall structure design, respectively, to determine the type of mold, mold unloading, the bow and arrow and location selection. To calculate mold a series of parameters, including blanking, bending force, and to determine the press models. Is as important parts of the mold design, the main components of the design, including punching concave die and bending concave convex mold, mold, positioning block and discharging rod design. Six, is a mold assembly, according to the design of mold parts assembly, through the CAD drawing the assembly drawing, to complete the whole design.

Keywords: cold stamping; mold; stamping parts

目 录

摘 要 0

ABSTRACT 0

绪论 1

1、冲压的概念、特点及应用 1

2、冲压的基本工序及模具 2

模具设计过程 3

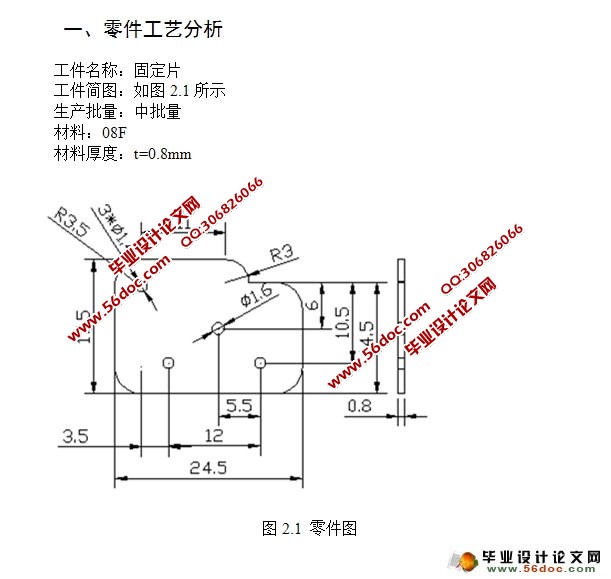

一、零件工艺分析 3

1.材料分析 3

2.结构分析 4

3.精度分析 4

二、制定工艺方案 5

1.冲裁工艺方案的确定 5

三、模具总体结构方案的确定 6

1.模具类型 6

2.操作与定位 6

3.卸料与出件方式 6

4.模架类型及精度 6

四、冲裁工艺计算 7

1.排样设计 7

2.确定冲裁模合理间隙值 8

3. 凸、凹模刀口尺寸的确定 8

4.冲裁工艺力的确定 13

五、冲裁模的零件选用和各零件的设计 19

1.凸模的结构设计 19

2.定位零件 23

3.卸料及出件零件 24

4.固定与紧固零件 27

5.导向零件 28

模具的总装 29

1.冲压模具制造技术要求 29

2、模具的结构及总装 29

总结 32

致谢 33

参考文献 34