圆形弯曲模设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

圆形弯曲模设计(含CAD零件图装配图)(开题报告,文献综述,设计说明书10000字,CAD图8张)

Circular bending die design

摘 要

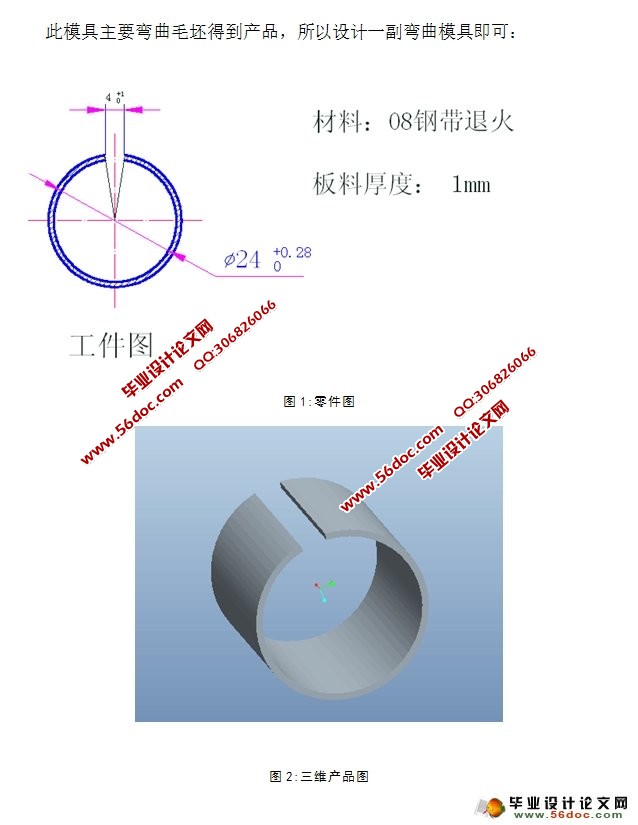

根据零件的设计尺寸要求、材料要求以及批量生产等要求,在分析好零件的工艺性之后,再制定工艺方案。再通过工艺计算来确定此模具的设计流程。模具加工工艺已经成为重要发展方向中的一项先进的制造工艺,如现在在汽车,航空等方面都是在广泛的应用。但是模具制造价格的高低也是直接影响到制件的价格和企业的经济效益。该模具设计的材料厚度比较薄只有1mm,拉深的高度也不是很高,可以二次弯曲成形,这里是用一次弯曲成形。精度也不算很高,一般都是在IT11-14级之间。在拉深成形没有达到我们所需要的工件时,可以再在后面加上整形这样一道工序来保证得到我们需要的模具。冲压成形技术早已经成为国内外比较成熟的一种金属成型加工工序,各种板料零件都是用该方法加工的。其的优点有:高效率、 轻重量、 精度好、成本低,而且还有自动化和机械化等优点。本次设计中,主要考虑筒形零件弯曲力的作用下成型工艺。弯曲是作为本零件的主要工艺。

关键词:冲压模; 弯曲; 单工序模。

ABSTRACT

According to parts of the design requirements of size, material requirements and production requirements, technology is good, after analyzing the parts, and then develop technology program. And then to determine the mold design process by process calculation. Mold processing technology has become an important development direction of advanced manufacturing processes, such as are now widely used in the automotive, aviation and so on. However, the manufacturing cost of the mold parts is also a direct impact on the cost and economic efficiency of enterprises. The mold design and material thickness is thin and only 1mm, drawing the height is not very high, you can bend the secondary success. Accuracy is not too high, generally between IT11-14 level. In deep drawing the work did not meet what we need, we can then followed by the shaping of such a process to ensure that we get the required mold. Stamping technology has already become more mature at home and abroad of a metal forming process, a variety of sheet metal parts are processed by this method. Its advantages are: high efficiency, light weight, good accuracy, low cost, but also the advantages of automation and mechanization. In this design, the main consideration blanking punching a cylindrical part and a curved molding process. Eventually blanking punching and then bending a part of the main forming process.

Keywords: composite mold; blanking; punching; bending;

目 录

绪 言 1

1 零件分析 3

2 弯曲模具的相关计算 5

2.1 弯曲的应用 5

2.2 弯曲件的质量分析 5

2.2.1、弯曲回弹值确定 5

2.2.2其他影响因素 7

3 零件工艺方案的确定 7

3.1 弯曲件的工艺性 7

3.1.1材料的适用性 7

3.2 弯曲件坯料展开尺寸的计算 8

4 弯曲力的计算与压力机的选用 10

4.1 弯曲力的计算 10

4 .2 压力机的选用 12

5 凸、凹模间隙的设计 13

5.1 凸、凹模工作尺寸的相关计算及部分零件设计 13

6. 弯曲工艺过程卡的编写 20

6.1模具整体结构 22

7 模具的零件详细清单 23

8 模具的工作原理 23

8.1 工作原理 23

8.2 模具总装 23

8.2.1 模具的使用需注意事项 24

总 结 24

致 谢 25

参考文献 26