压圈弯曲模设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

压圈弯曲模设计(含CAD零件图装配图)(开题报告,文献综述,设计说明书12900字,CAD图5张)

Pilot Study of Compression ring bending design

摘 要

本次设计是压圈弯曲模设计,体现了典型的弯曲模具的设计、内容和方向,具有一定的设计意义。通过对该模具的设计进而一步的加强了设计者弯曲模设计的基础知识,为以后能够设计出更加复杂的弯曲模具打下了坚实的基础以及吸取了深刻的经验。

本次设计通过运用弯曲成型工艺以及模具设计的基础知识,首先通过板料材料的性能要求分析本次弯曲模的弯曲工艺;随后计算出获得合适板料的冲裁和弯曲力的相关计算,便于选择压力机型号和压力机吨位的确定;最后通过弯曲工件的特性,确定模具的设计参数、设计要点以及各零件的设计和选取。

模具设计过程是一种需要反复考究和有一定经验性的设计过程,随着前期发展积累了大量丰富的冲压工艺技术的资料和数据,在设计模具时必然是需要利用这些数据的,包括弯曲模常用的工艺数据,以及标准件的选取和压力机型号或是吨位参数的选取等等。

本次设计的压圈弯曲模结构左右对称较为简单、运行稳定、性能比较可靠,能够适应批量生产制件,提高了生产效率的同时也降低劳动强度和生产成本。

关键词:弯曲模; 板料; 冲压

ABSTRACT

This design is the bending die design of the press circle, which reflects the design, content and direction of the typical bending die. Through the design of the mould and further strengthen the designer bending die design on the basis of knowledge, for the future to design more complex bending die laid a solid foundation and the profound lessons of experience.

This design through the use of bending forming process and die design of basic knowledge, first of all through the performance of the plate material requirements analysis of the bending die of bending process; then calculated to obtain appropriate sheet of punching and bending force calculation, easy to determine selective press model and press tonnage; finally through the characteristics of bending workpiece to determine the mold design parameters, design points and various parts of the design and selection.

Die design process is a need to repeatedly stress and some empirical design process, as the early development of accumulated a wealth of stamping technology of information and data, in the mold design must be need to use these data, including bending die commonly used process according to, as well as standard parts of the selection and press model or tonnage parameters are selected, and so on.

About the design of the pressing ring bending die structure is symmetric and simple, stable operation, reliable to adapt to the batch production of parts, improve the production efficiency and also reduce labor intensity and production cost.

Key words:Bending die; sheet metal; stamping

目 录

一 弯曲工艺性分析..................................................1

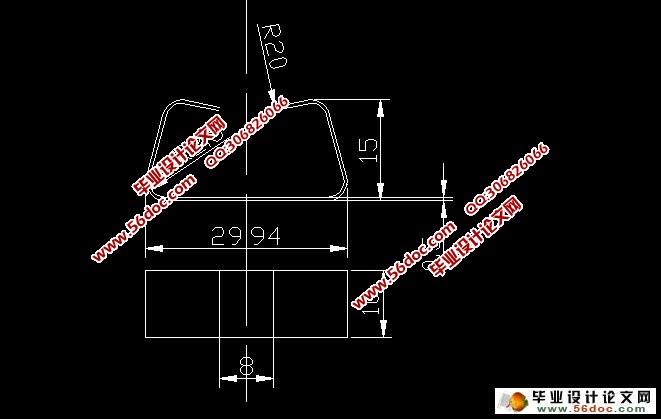

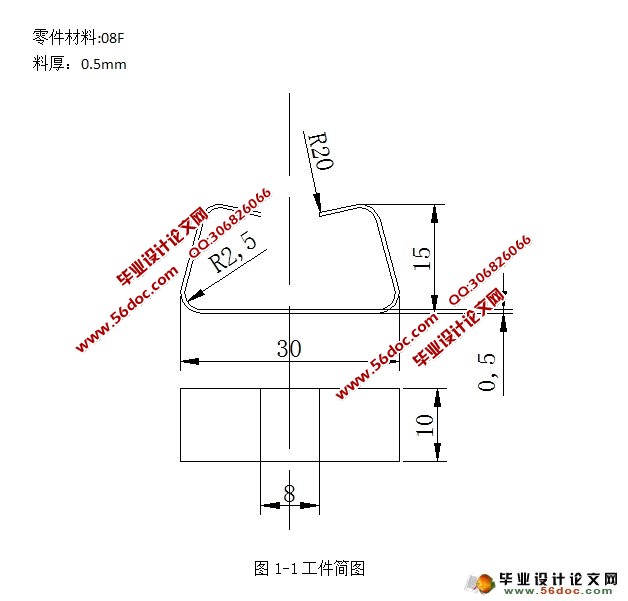

1.1 分析零件的冲压工艺性并确定工艺方案..........................1

1.2 弯曲件的工艺性..............................................2

1.3 最小弯曲半径................................................2

二 弯曲件的结构工艺性分析..........................................4

2.1 最小弯曲半径................................................4

2.2 弯曲件形状与尺寸的对称性....................................4

三 改进零件的结构设计..............................................5

3.1 采用热处理工艺..............................................5

3.2 从模具结构采取措施..........................................5

四 毛坯尺寸、排样及回弹的计算.......................................7

4.1 毛坯尺寸....................................................7

4.2 确定毛坯尺寸................................................7

4.3 排样........................................................8

4.4 回弹量的计算...............................................11

五 冲裁和弯曲的相关计算...........................................12

5.1 冲裁力.....................................................12

5.2 冲裁时的卸料力和推件力.....................................12

5.3 冲压模具压力中心的确定.....................................13

5.4 冲压模具的闭合高度.........................................13

5.5 自由弯曲时的弯曲力.........................................13

5.6 校正弯曲时的弯曲力.........................................14

5.7 弯曲时的顶件力和压料力.....................................15

5.8 压力机吨位的确定...........................................15

六 弯曲模主要工作零件结构参数的确定...............................16

6.1 弯曲凸模和凹模的圆角半径...................................16

6.2 凹模深度...................................................16

6.3 弯曲凸模和凹模之间的间隙...................................17

6.4 凸凹模工作部分的尺寸与公差.................................17

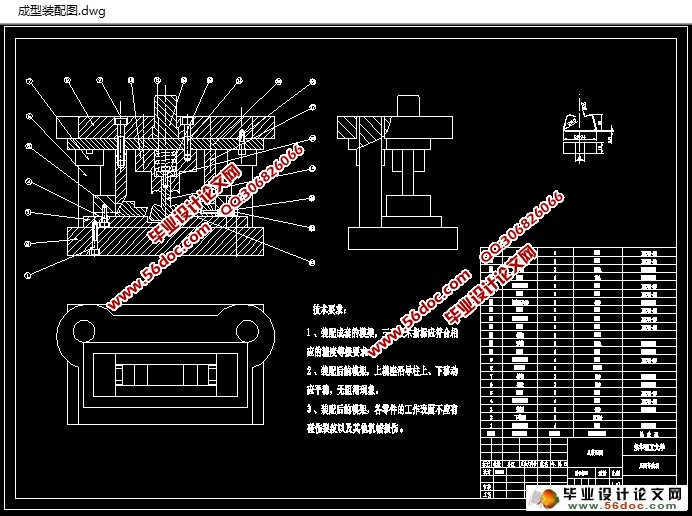

七 主要零部件的设计...............................................19

7.1 凸凹模的设计...............................................19

7.2 模架及其他零件的设计.......................................20

八 模具的装配图...................................................23

九 总结...........................................................24

致谢...............................................................25

参考文献...........................................................26