一种单输入多输出结构分动箱设计

无需注册登录,支付后按照提示操作即可获取该资料.

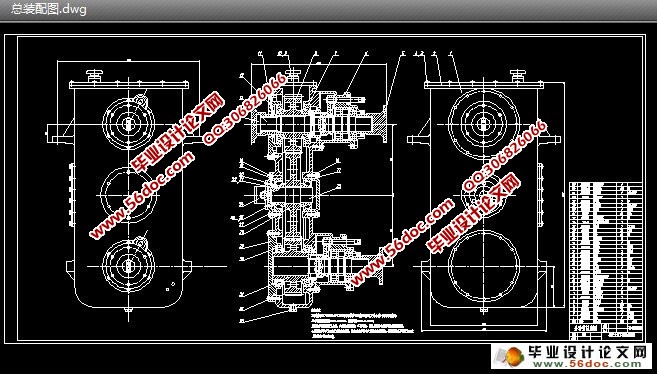

一种单输入多输出结构分动箱设计(任务书,开题报告,毕业论文说明书18900字,CAD图纸3张)

【摘要】分动箱的设计是鉴于工程实际的需要,设计出一种能使车辆在恶劣的环境下通过动力分配实现由驱动行车向驱动车载设备转换的机构。通过变速箱的动力输入,经齿轮、滑移齿轮、拨叉、花键、轴、轴承等的连接和啮合实现动力由一轴向多轴的动力分配。

在设计过程中,首先确定传动方案,通过比较选择最好的一种,然后确定传动轴上的各部分零件以及各零件的定位,查表选取标准零件并进行校核使其满足一定的强度和刚度要求,并且还要考虑一定的经济性,最后,把各零件与箱体进行装配,结合各轴的传动速度确定润滑装置和方式及加油、出油和检测油面的装置和位置,从而保证传动的平稳性和良好性。

虽然设计中遇到了众多的困难,但通过老师的辛勤指导和查阅相关书籍资料,设计效果还是比较满意,能够实现工程低速车辆的要求并具有一定的经济效益。

【关键词】分动箱;确定传动方案;齿轮;轴;装配

A single input multiple output structure transfer case design

Students:Fu Hong,Machanics Department

Tutor:Sun Zhifang, Machanics Department

[Abstract] The design of transfer case is in view of the needs of engineering practice, the design of institutions can make the vehicles in the bad environment work through the power distribution achieved by two -wheel drive to four-wheel drive conversion. Through the power- input of transfer case, the power is distributed rang an axial from multiaxial axial due to the connection and mesh of the gear, sliding gears, dialing the fork, spline, shaft, bearing.

In the process of design, to begin with, identify a series of transmission scheme, compared with these and choose the best one. Then determine the transmission parts and the localization of parts, check a charm and select standard’s parts and made a test in order to make it satisfy the requirements of cerrtain intensity and rigidity, and consider certain economic. Finally, the parts should be assembled with cabinet, combined with the axis transmission speed to make sure the lubrication device and way ,and the device and position of refueling, oil outlet and testing oil to ensure the smoothness and good of transmission .

As for the design ,I meet many difficulties, with the help of the hard guidance of teacher and refering to the relevant books material, the effect still is quite satisfied, it can realize the the request of lower vehicles and have certain economic benefits..

[Key words]the design of transfer case ;transmission scheme;gear ; shaft ;assemble.

毕业设计所需资料及原始数据

最大输入功率:275kW

传动比:1:1

最高输入转速:2100rpm

分动箱所驱动的车载设备工作时最大扭矩为6000N.m

目录

任务书……............................…………………………………………………………… Ⅰ

开题报告………………………………………………………………………………… Ⅱ

指导教师审查意见……………………………………………………………………… Ⅲ

评阅教师评语…………………………………………………………………………… Ⅳ

答辩会议记录…………………………………………………………………………… Ⅴ

中文摘要………………………………………………………………………………… Ⅵ

外文摘要………………………………………………………………………………… Ⅶ

前言 1

1选题背景 2

1.1 概述 2

1.2题目来源 2

1.3研究的目的和意义 2

1.4设计原则和技巧 3

1.5 国内外发展方向 6

2 方案论证 8

2.1 传动方案选择 8

2.2齿轮强度的设计方法 8

2.3结构设计 2

3过程设计 ...3

3.1计算传动装置的运动和动力参数 3

3.2传动齿轮的设计计算 5

3.3轴的设计计算 14

3.4花键的设计和计算 19

3.5轴承的选取和校核 21

3.6箱体的设计计算 22

3.7分动箱附件结构设计 23

3.8分动箱的润滑和密封 24

3.9结构设计总述 32

4 总结 33

参考文献 33

致谢 34