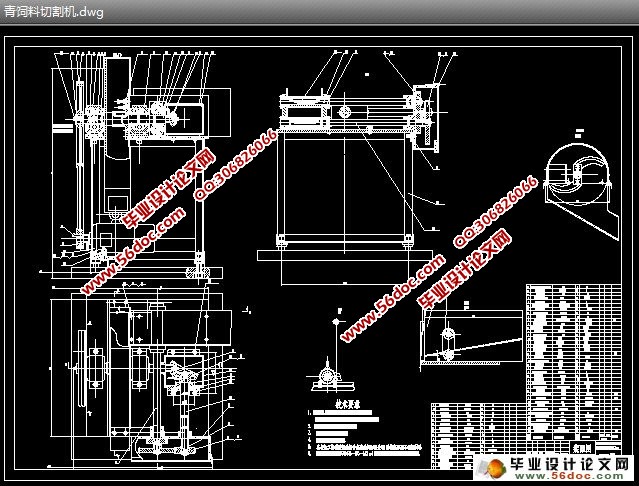

青饲料切割机的设计(农业机械)(含CAD零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

青饲料切割机的设计(农业机械)(含CAD零件图和装配图)(选题审批表,任务书,开题报告,中期检查表,论文说明书11100字,CAD图6张)

摘 要: 一种青饲料切割机,由装在同一传动轴上的破碎,切碎两种功能的机构构成.破碎机构主要由刀齿板、切刀、刮刀及辊筒构成.加工块茎类物料时,经刀齿的划割,切刀的切割,刮刀的进一步破碎,完成加工过程;同时,可利用切碎机构加工藤蔓、杆叶类青饲料;并采用辊压轮对藤蔓进行自动进给.拆下破碎部件,换上磨碎齿板,又可作为薯类淀粉初加工机具.因此,既能满足青饲料加工要求,又能加工薯类淀粉,适应农村养殖业的需要.

关键词: 破碎、切碎、切刀、辊筒、辊压轮

Green fodder cutting machine design

Abstract:A green fodder cutting machine ,by the same equipment on the drive shaft broken, shredding function of the two bodies constituted . Broken bodies is main made up of plate cutters, machetes, blade and roller. Tuber processing materials, with the cutter tooth is removed, the cutter cutting, scraping further broken completed processing . Meanwhile, it will use the sap processing shredding bodies, leveraged leaf green fodder,and using roller round to get the sap Automatic Feed . Broken parts removed and replaced teeth grinding plate, and could serve as the beginning of potato starch processing machines , Therefore, it can satisfy green fodder processing requirements, while potato starch processing, aquaculture industry suitable to rural needs .

Key Words:Breakers;Shredding;Cutter;Roller ;Rolling wheel

本设计是利用破碎辊筒上的齿、刀部件,配合作用,减少对物料的挤压、碰撞的机会,降低了块茎类饲料加工的浆状体;同时在加工藤蔓、杆叶类饲料时采用辊压轮进给,大大提高了送料时的人身安全;加之同破碎机构安装在同一传动轴上的切碎机构。即可完成块茎、块根类青饲料的加工,又可同时加工藤蔓、杆叶类饲料。不但简化了设备,又避免了采用不同的传动轴,共用同一动力,操作使用时的麻烦。破碎辊筒上的刀齿板、切刀、刮刀可拆下,换上磨碎齿板,又具有薯类淀粉加工能力。因而它有结构简单,适应性强的特点,能充分满足农村,特别是山区农村推广

实现原理介绍

该机主要由传动轴Ⅰ和装在其一端的V带轮,装在其中部的破碎辊筒和切碎刀盘,装在其一端的变速锥齿轮和传动轴Ⅱ上的变速锥齿轮和直齿轮及进给轴Ⅲ、Ⅳ,装在支撑固定它们的机架下部的电动机,主动轮及传动皮带,加之安装在机架上的喂料台,进料斗,机壳等构成,要点是破碎辊筒的滚动面上安装了由刀齿板,切刀,刮刀组成的共同完成对块茎块根类青饲料破碎的破碎机构,切碎机构由安装在传动轴一端的切碎刀盘及其上的动刀片,加之固定在机架相应位置上,能在刀盘转动过程中,与动片构成剪切动作的定刀片构成。为使破碎和切碎能同时进行,把破碎辊筒,切碎刀盘装在同一传动轴上。传动轴安装在机架上,动力由机架下部的电动机及其主动轮,通过皮带传给安装在传动轴一端的从动轮,驱动传动轴运转使安装在中部的破碎辊筒及其切刀盘工作。机架上靠切碎刀盘一侧,制作了切碎机构喂料台、自动进给辊压轮及刀盘罩;位于传动轴中部的破碎辊筒上,装有机壳和进料斗,二者用小螺杆连为一体;主动轮与从动轮间套有皮带防护罩;机架下部制作了切碎,破碎物料的出料斗。其中,喂料台,刀盘罩、机壳、进料斗、皮带防护罩,出料斗均连接固定在机架上。破碎辊筒上的刀齿板、切刀、刮刀等用螺钉固定在滚筒的滚动面上,且使刀齿板和切刀有5-10度的螺旋角。这样,就够成一个青饲料切碎机。若要作为暑类淀粉加工设备,则可将磨碎齿板替换下破碎辊筒上的刀齿板,切刀和刮刀。磨碎齿板能在辊筒的旋转力带动下,将薯类打磨成浆体,达到加工淀粉的目的[2]。

主要技术参数:生产率500Kg/h

目 录

摘要............................................ ....................................................................................................................1

关键词............................................................................................................................................................1

1 前言........................................................................................................................................................1

2 总体设计...............................................................................................................................................2

2.1 方案的筛选...........................................................................................................................2

2.2 实现原理介绍.......................................................................................................................2

2.3 整体传动比的分析计算....................................................................................................3

3 传动设计...............................................................................................................................................5

3.1 电动机的选型.......................................................................................................................5

3.2 V带传动的设计...................................................................................................................5

3.2.1 V带轮的设计要求............................................ .......................................................5

3.2.2 带轮的材料.................................................................................................................5

3.2.3 V带轮的结构..............................................................................................................5

3.2.4 相关计算.....................................................................................................................6

3.2.5 带轮的结构设计........................................................................................................7

3.2.6 V带轮的结构参数....................................................................................................8

3.3 锥齿轮的设计......................................................................................................................9

3.3.1 选择齿轮材料...........................................................................................................9

3.3.2 选定齿轮精度等级..................................................................................................9

3.3.3 按接触疲劳强度设计小齿轮分度直径.............................................................9

3.3.4 计算主要尺寸与参数............................................................................................10

3.4 圆柱齿轮的设计................................................................................................................12

3.4.1 选定精度等级,材料及齿数.................................................................................12

3.4.2 按齿面接触强度设计............................................................................................12

3.4.3 按齿根弯曲强度设计............................................................................................14

3.4.4 几何计算...................................................................................................................15

3.4.5 验算............................................................................................................................16

4 轴与校核............................................................................................................................................17

4.1 轴的设计.............................................................................................................................17

4.1.1 主轴Ⅰ的设计..........................................................................................................17

4.1.2 传动轴Ⅱ的设计.....................................................................................................18

4.1.3 传动轴Ⅲ、Ⅳ的设计............................................................................................19

4.2 校核......................................................................................................................................20

4.2.1 主轴Ⅰ的校核..........................................................................................................20

4.2.2 调心球轴承的寿命计算.......................................................................................25

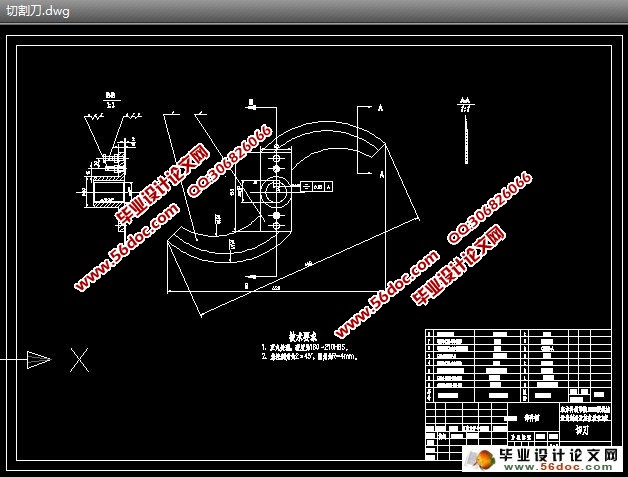

5 刀的设计............................................................................................................................................26

5.1 切刀的设计.......................................................................................................................26

5.1.1 切刀材料...................................................................................................................26

5.1.2 对切刀的要求..........................................................................................................26

5.1.3 选用或设计刀片时应满足的要求.....................................................................27

5.1.4 刀片刃口几何形状及常用刀片形状.................................................................27

5.1.5 刀的滑切与正切分析............................................................................................27

5.1.6 钳住物料的条件分析............................................................................................29

5.1.7 刀的安装....................................................................................................................30

6 进给机构与机架的设计.................................................................................................................31

6.1 进给机构的设计................................................................................................................31

6.2 机架的设计.........................................................................................................................32

7 总结.....................................................................................................................................................32

参考文献...................................................................................................................................................32

致谢............................................................................................................................................................32