盘式制动器制动系设计

无需注册登录,支付后按照提示操作即可获取该资料.

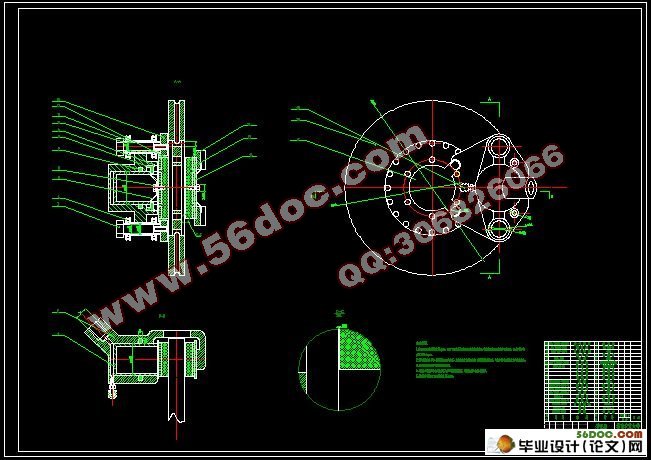

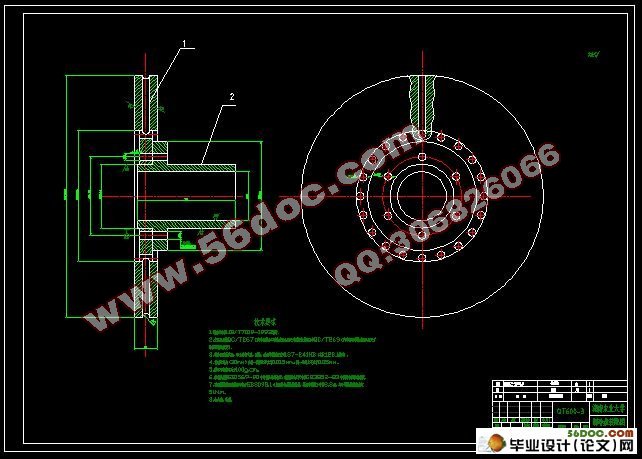

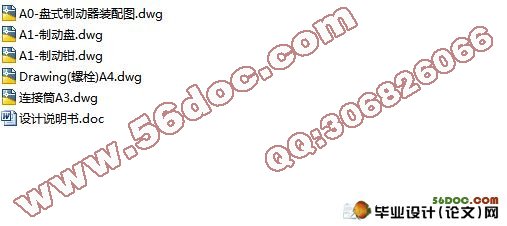

盘式制动器制动系设计(说明书14000字,cad图纸5张)

摘 要:汽车制动系统直接影响着汽车行驶的安全性和停车的可靠性。随着高速公路的迅速发展和车速的提高以及车流密度的日益正大,为了保证行车安全、停车可靠,汽车制动系的可靠性显得日益重要。也只有制动性能良好、制动系工作可靠的汽车,才能充分发挥其动力性能。

盘式制动器又称为碟式制动器,这种制动器散热快、重量轻、构造简单、调整方便,特别是高负载时耐高温性能好,制动效果稳定,在冬季和恶劣路况下行车,盘式制动比鼓式制动更容易在较短的时间内令车停下。本设计内容包括汽车制动器的功能与设计要求,结构方案的分析,制动力的分配,制动器主要零件的选择及主要参数的选取,制动器各种参数的计算,主要零件的装配尺寸链的分析计算。在设计中也涉及到同步系数的选取、制动器效能因素的选取、制动力矩的计算,以及制动器主要元件选取,最后对设计的制动器进行校核计算。由制动器设计的一般原则,综合考虑制动效能、制动效能稳定性、制动间隙调整简便性、制动器的尺寸和质量及噪声等诸多因素设计本产品

关键词:盘式制动器;制动系统;同步系数

Design of the braking system of disk brakes

Abstract:Automotive vehicle brake system directly affects the driving safety and parking reliability. With the rapid development of highway and the increased speed limit as well as the increasing traffic density, in order to ensure driving and parking safety, the reliability of automotive brake systems has become increasingly important. Only excellent reliable car braking system can fully play its role of adjusting the car’s dynamic performance.

Disc brake, also known as dish brakes, it brakes and ventilates fast and is also light weight. Its simple structure, easy clearance adjustment, outstanding performance at high temperature with heavy load, better working stability enables it to stop the car quicker than traditional drum brakes at winter and bad road conditions.

The function and design requirement of the vehicle brake system, analysis of the construction scheme, distribution of braking torque, selection of the main components as well as the main coefficient calculation of the system, are all concluded in this paper. Based on the primary principle of brake designing, taking the efficiency, stability, and easy clearance adjustment as well as the size, quality and noise making into consideration, this paper covers many aspects while designing.

Key words:disc brake, brake system, synchronization coefficient

目 录

摘要…………………………………………………………………………………………1

关键词………………………………………………………………………………………1

1 前言 ……………………………………………………………………………………2

2 制动器的结构形式及选择 ……………………………………………………………4

2.1 盘式制动器的结构形式及选择 ………………………………………………4

2.1.1 固定钳式盘式制动器 …………………………………………………4

2.1.2 浮动盘式制动器 ………………………………………………………5

2.2 制动盘的分类及选择 …………………………………………………………5

2.3 奥迪A8型轿车盘式制动器的结构及工作原理………………………………6

3 制动器的只要参数及选择 ……………………………………………………………7

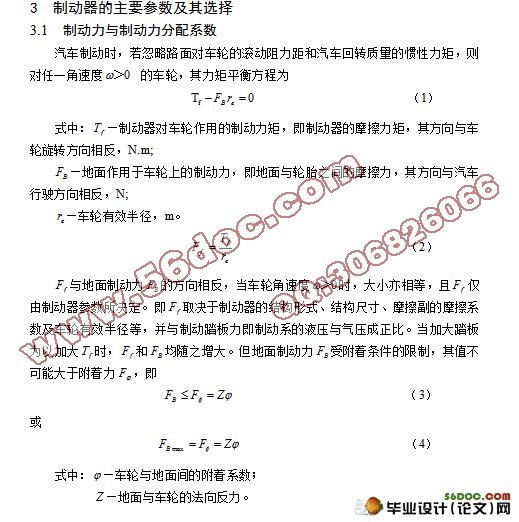

3.1 制动力与制动力的分配选择 …………………………………………………7

3.2 同步附着系数…………………………………………………………………12

3.3 制动强度和附着系数利用率…………………………………………………13

3.4 制动器最大制动力矩…………………………………………………………14

3.5 利用附着系数与制动效率……………………………………………………15

3.6 制动器因数……………………………………………………………………17

3.7 盘式制动器主要参数及摩擦系数的确定……………………………………18

4 制动器的设计计算……………………………………………………………………19

4.1 摩擦衬块的磨损特性计算……………………………………………………19

4.2 制动器的热容量和升温的核算………………………………………………21

4.3 盘式制动器制动力矩计算……………………………………………………22

5 制动器只要部件的结构设计与计算…………………………………………………24

5.1 制动盘…………………………………………………………………………23

5.2 制动钳…………………………………………………………………………23

5.3 制动块…………………………………………………………………………24

5.4 衬块警报装置设计……………………………………………………………25

5.5 摩擦材料………………………………………………………………………25

5.6 制动器间隙……………………………………………………………………25

5.7 固定摩擦片铆钉的剪切应力计算……………………………………………25

6 制动驱动机构的形式选择与设计计算………………………………………………26

6.1 伺服制动器的结构形式选择…………………………………………………26

6.2 制动管路的多回路系统………………………………………………………26

7 结论……………………………………………………………………………………28

参考文献 …………………………………………………………………………………28

致谢 ………………………………………………………………………………………29

附录…………………………………………………………………………………………29