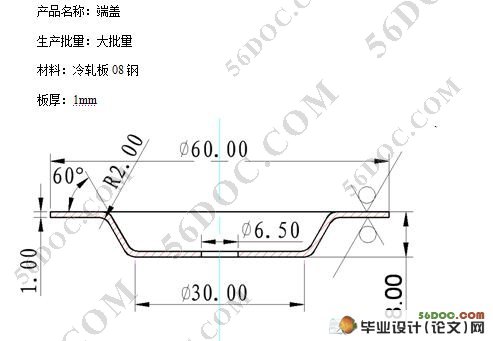

端盖冲压成型工艺及模具设计(附加工工艺卡)(caxa)

无需注册登录,支付后按照提示操作即可获取该资料.

端盖冲压成型工艺及模具设计(附加工工艺卡)(caxa)(含任务书,中期检查报告,毕业论文说明书9000字,caxa图纸)

摘要:我所学习的专业是模具设计与制造专业,这次的毕业设计是端盖冲压成型工艺及模具设计。该设计结合大学三年来所学习的专业知识和CAD软件所设计出的一套冲压模。

本文首先简要的概述了冲压模在社会领域中的作用及其以后的发展方向,点明模具设计的重要意义。然后依据工件图进行工艺性分析,进而确定了设计方案,计算出模具工作部分的尺寸,设计出工作零部件;然后依据设计要求选择出各个标准零部件,然后设计出模具的总装配图。在设计中,最重要的就是设计方案的确定、坯料的计算和选取以及工作零部件的设计,这是设计的关键,这些设计的正确与否直接关系到成本的高低和设计模具能否正常工作;在设计的最后,总结了自己的心得和体会,并对我的指导老师表示感谢。

通过本次毕业设计使我不仅掌握了冲压模具设计的一般流程,更学习到了好多课本上没有学习到的知识,使我受益匪浅。

关键词:模具设计与制造 CAD软件 工艺性分析

Cover stamping forming process and die design

Abstract:I studied the professional is a professional mold design and manufacture of the cover of the graduation project is stamping forming process and die design. The design study by the University over the past three years of professional expertise and CAD software to design a stamping die.

This article begins with a brief overview of the stamping die in the social field and its future development direction, specifically the importance of mold design. Workpiece and then based on analysis of process maps and to identify the design, to calculate the work of some of die size, the design of the work of parts and components; the basis of design requirements and then select all the standard components, and then design a mold of the total assembly. In the design, the most important thing is to determine the design, calculation and select the blank, as well as parts of the design work, which is the key to the design, the design is right or not directly related to the high and low cost tooling and design can work properly ; in the design of the final, summed up their own ideas and experience, and my teacher said.

The adoption of the graduation project, I not only mastered the general stamping die design process, but also learn a lot of textbook knowledge is not learned, I benefited from.

Key words: mold design and manufacturing process analysis of CAD software

#p#副标题#e#

目 录

绪论 …………………………………………………………………………1

第一章. 冲压件的工艺分析 ………………………………………………5

第二章. 冲压件主要工艺参数的计算………………………………………5

毛坯工艺参数的计算……………………………………………………6

(1)确定修边余量………………………………………………………6

(2)判断能否一次拉成…………………………………………………6

(3)确定压边装置………………………………………………………6

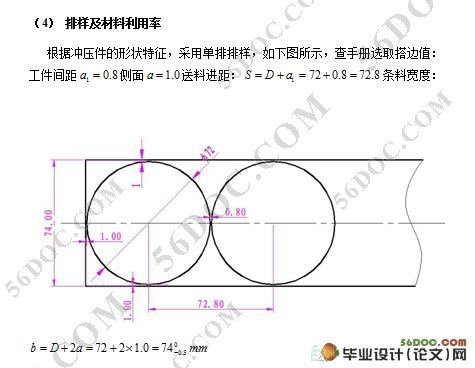

(4)排样及材料利用率…………………………………………………6

第三章.工序冲压力的计算…………………………………………………7

(1) 落料力的计算…………………………………………………………7

(2) 卸料力的计算…………………………………………………………7

(3) 拉深力的计算…………………………………………………………7

(4) 压边力的计算 ……………………………………………………… 7

(5) 冲孔力的计算…………………………………………………………8

(6) 推件力的计算…………………………………………………………8

(7) 总的冲压力计算………………………………………………………8

第四章.冲压设备的选择……………………………………………………8

第五章.模具主要工作零部件的计算 ………………………………………8

(1) 落料 …………………………………………………………… 9

(2) 冲孔…………………………………………………………… 9

(3) 拉深………………………………………………………… …9

第六章.弹性元件的选择……………………………………………………10

(1) 弹簧的选择………………………………………… …………10

(2) 橡胶的选择………………………………………………… …11

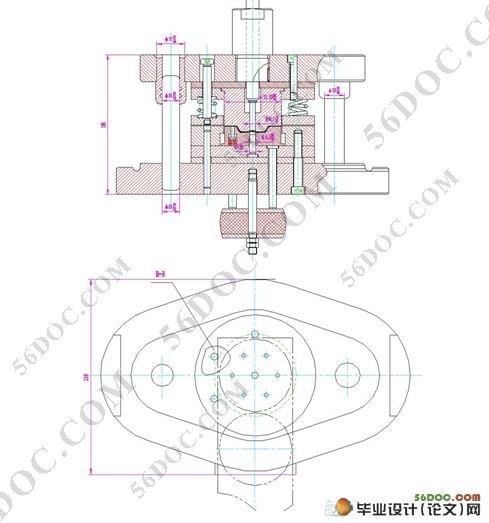

第七章.标准模架的选择…………………………………………… ……11

第八章.冲压设备基本参数的校核 ………………………………………12

(1) 模具闭合参数的校核………………………………………… 12

(2) 冲裁所用总压力的校核…………………………………………13

(3) 模具安装尺寸的校核………………………………………… 13

第九章.拉深模的装配与调试 ……………………………………………16

第十章.模具主要零件的加工……………………………………… ……19

设计总结 ……………………………………………………………………21

致谢…………………………………………………………………………22

参考文献 ……………………………………………………………………23