端盖冲压成形工艺及模具设计

无需注册登录,支付后按照提示操作即可获取该资料.

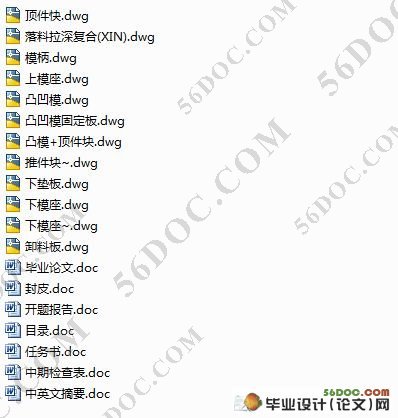

端盖冲压成形工艺及模具设计(含任务书,中期检查报告,毕业论文说明书10000字,cad图纸12张)

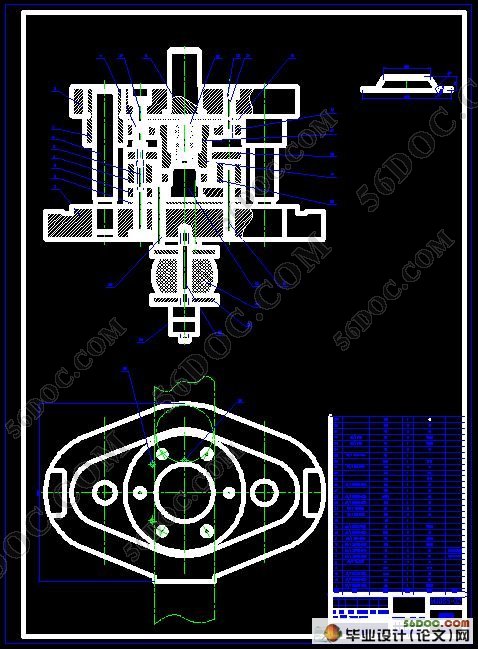

摘要:设计着重介绍了工件的成型工艺,及模具结构设计。通过对工件的工艺分析,确定了工艺方案。并设计了一套正装复合模具。在设计同时利用参考资料,确定了各工作零件的尺寸。并较多的考虑了模具结构的调整性、易更换性及模具成本。同时在模具设计内容中融汇了冲压模具的不同加工方法、加工工艺及装配工艺,对初学冲压模具模设计者有一定的参考价值。本设计从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词: 复合模。

Lamp screen pressing formed technology and mold design

Abstract: The design introduced emphatically the workpiece takes shape the craft, and mold structural design. Through to the workpiece craft analysis, has determined the craft plan. And has designed set of true things compound molds. Uses the reference during the design, has determined each work components size. And many considerations mold structure adjustment, easy replacement and mold cost. Meanwhile has blended together the ramming mold different processing method in the mold design content, the processing craft and the assembly craft, to begins studies the ramming mold mold designer to have the certain reference value. This design designs from the mold to the spare part processing craft as well as the assembly craft and so on carries on the detailed elaboration, and carries on each important components using CAD the design.

Key words: the compound mold.

#p#副标题#e#

目 录

1、绪论……………………………………………………………………………1

1.1 国内模具的现状和发展趋势………………………………………………1

1.1.1国内模具的现状……………………………………………………………1

1.1.2国内模具的发展趋势………………………………………………………2

1.2 国外模具的现状和发展趋势………………………………………………2

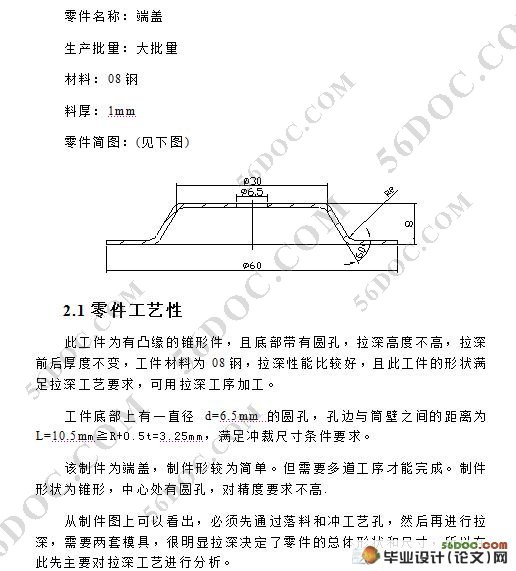

2、冲压工件的工艺分析…………………………………………………………5

2.1 零件工艺性…………………………………………………………………5

2.2 工艺方案的确定……………………………………………………………6

3、工艺性计算……………………………………………………………………7

3.1 计算毛坯尺寸………………………………………………………………7

3.2 排样设计……………………………………………………………………7

3.3 条料宽度、导料板间距离和材料利用率的计算……………………………9

3.4计算凸、凹模刃口尺寸………………………………………………………9

3.41冲孔凸、凹模刃口尺寸的计算………………………………………………9

3.42 落料凸、凹模刃口尺寸的计算…………………………………………… 10

3..43拉深凸、凹模尺寸的计算……………………………………………………11

3.44拉伸凸、凹模的圆角半径的计算……………………………………………12

3.5冲压力得计算…………………………………………………………………12

3.51.落料力、冲孔力、卸料力、推件力…………………………………………12

3.52.拉深力…………………………………………………………………………12

3.53.压边力…………………………………………………………………………13

3.54.顶件力…………………………………………………………………………14

4、模具工作部分的设计…………………………………………………………15

4.1落料凸、凹模的结构设计……………………………………………………15

4.2冲孔 6.5的凸模设计………………………………………………………15

4.3模柄……………………………………………………………………………15

4.4垫板……………………………………………………………………………16

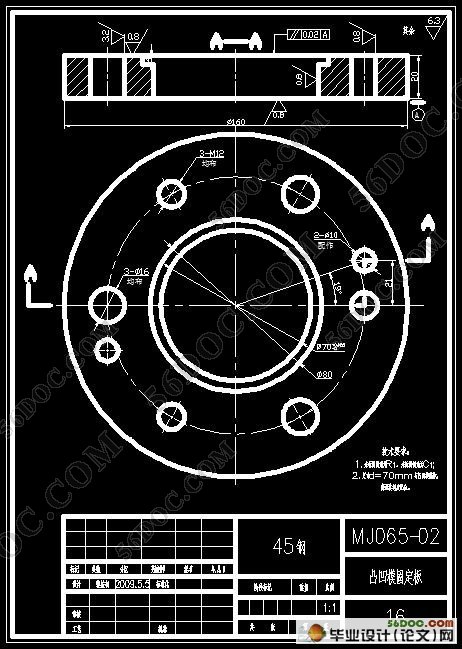

4.5凸模固定板……………………………………………………………………16

4.6凸凹模固定板…………………………………………………………………17

4.7落料凹模………………………………………………………………………17

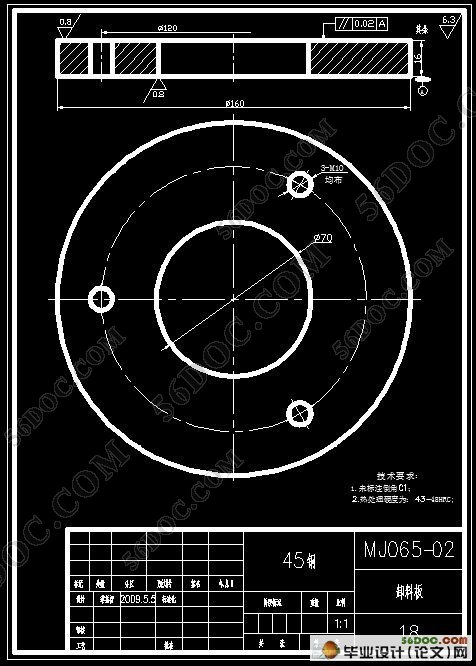

4.8卸料板…………………………………………………………………………18

4.9顶件块 ………………………………………………………………………19

4.10凸凹模…………………………………………………………………………20

4.11模具其它部件的选用…………………………………………………………20

4.12选用模架、确定闭合高度及总体尺寸………………………………………21

4.13.冲压设备的选择………………………………………………………………22

5、模具的装配……………………………………………………………………24

5.1模具总装图……………………………………………………………………25

结束语………………………………………………………………………………26

致谢 ………………………………………………………………………………28

参考文献……………………………………………………………………………29