弯板冲压弯曲模设计(附加工工艺卡)

无需注册登录,支付后按照提示操作即可获取该资料.

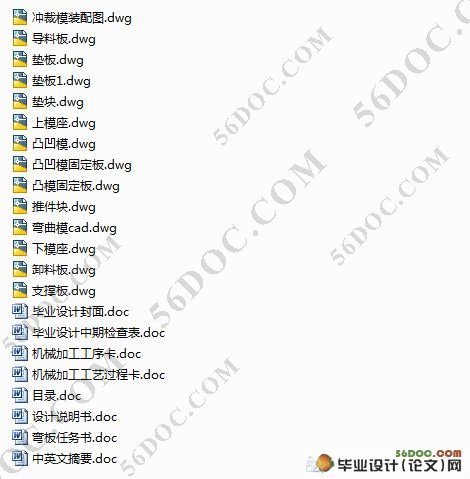

弯板冲压弯曲模设计(附加工工艺卡)(含任务书,中期检查报告,毕业论文说明书10000字,cad图纸14张)

摘要

本设计为弯板落料冲孔复合模及弯曲模设计。通过对该零件模具的设计,进一步加强了设计者冲压模设计的基础知识,为设计更复杂的冲压模具做好了铺垫和吸取了更深刻的经验。

本设计运用冲压成形工艺及模具设计的基础知识,首先分析了冲压件的外形及用处性能要求,为选取模具的类型做好了准备;然后计算了冲压力,便于选取压力机;最后计算了制件的压力中心,确定模具的设计参数、设计要点及推出装置的选取。

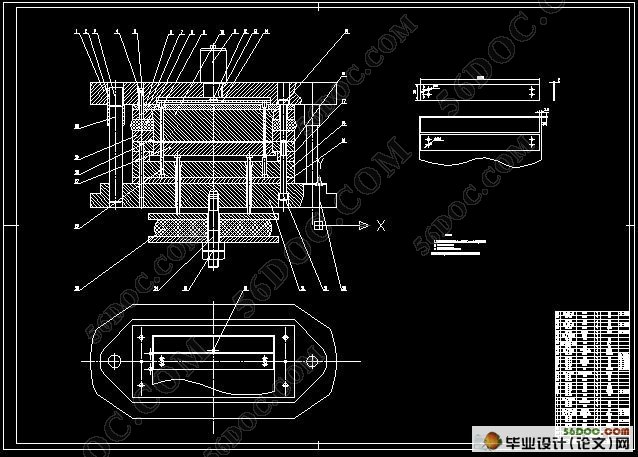

设计复合模,首先要设计条件排样图。弯板展开后的形状简单。由于零件外形尺寸为自由尺寸对精度要求不高,为了提高材料的利用率减少冲裁力,虽然这时会使零件外形尺寸公差等级降低但是经过筹兼顾,全面考虑。这里我们采用少废料排样。

凹模采用整体式凹模,各冲裁的凹模孔均采用线切割机床加工,安排凹模在模架上的位置时要依据计算压力中心与模柄中心重合。

关键词:复合模 、大批量 、弯板、少废料排样 、导正销 、卸料板

弯板冲压弯曲模设计

Abstract:

This design falls the material punch holes superposable die and the bending die design for the angle iron.Through to this components mold design, further strengthened the designer to flush the die design the elementary knowledge, for designed the more complex ramming mold to complete the upholstery and to absorb a more profound experience.

This design the elementary knowledge which designs using the ramming forming craft and the mold, first has analyzed the pressing part contour and the use performance requirement, for selected the mold the type to prepare for; Then has calculated the ramming strength, is advantageous for selects the press; The last count workpiece center of pressure, the definite mold design variable, the design main point and promoted the installment the selection.

The design superposable die, first must a design conditions row of specimen map.The angle iron launches after the shape to be simple.Because the components external dimensions are not high for the free size to the precision request, in order to enhance the material the use factor reduction blanking force, but although could cause the components external dimensions grade of tolerance by now to reduce the process to plan the proper attention to both, comprehensive consideration.Here we use a few waste material row of type.

The concave mold uses the integral-type concave mold, various blankings concave nib uses the line cutting engine bed processing, arranges the concave mold when pould frame position must rest on the pressure rating center and the die shank center superposition.

Key word: The superposable die, the mass, the angle iron, a few waste material row of type, lead are selling, unload the yard lumber

#p#副标题#e#

目 录

1 绪论………………………………………………………………………………1

1.1国内模具的现状和发展趋势……………………………………………………1

1.2国外模具的现状和发展趋势 …………………………………………………3

1.3弯板模具设计与制造方面 ……………………………………………………3

1.3.1弯板模具设计的设计思路……………………………………………………4

1.3.2弯板冲孔落料弯曲件模具设计的进度………………………………………4

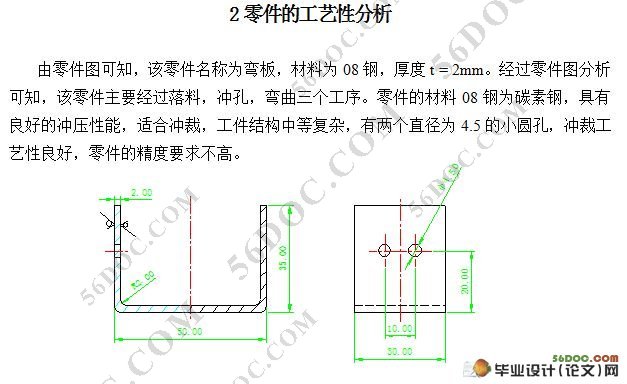

2零件的工艺性分析……………………………………………………………5

2.1弯曲冲孔的工艺分析……………………………………………………………5

2.2工艺方案的确定…………………………………………………………………5

2.3 冲裁排样方案的确定……………………………………………………………6

3主要工艺参数的计算………………………………………………………………8

3.1 冲裁工艺计算……………………………………………………………………8

3.1.1 冲孔落料复合…………………………………………………………………8

3.2 U形弯曲件的工艺计算…………………………………………………………10

4模具主要零部件的设计……………………………………………………………12

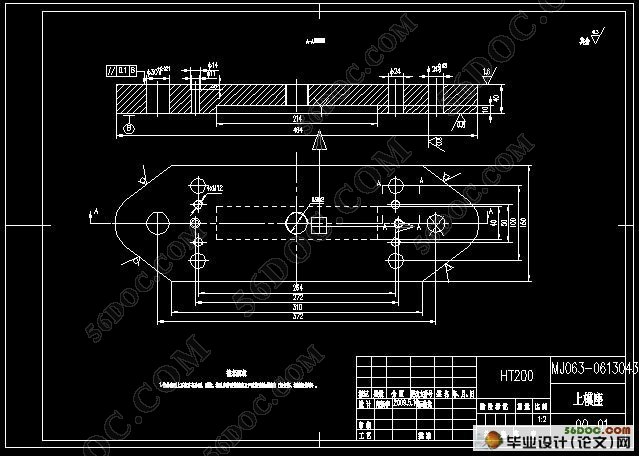

4.1工作零部件的设计………………………………………………………………12

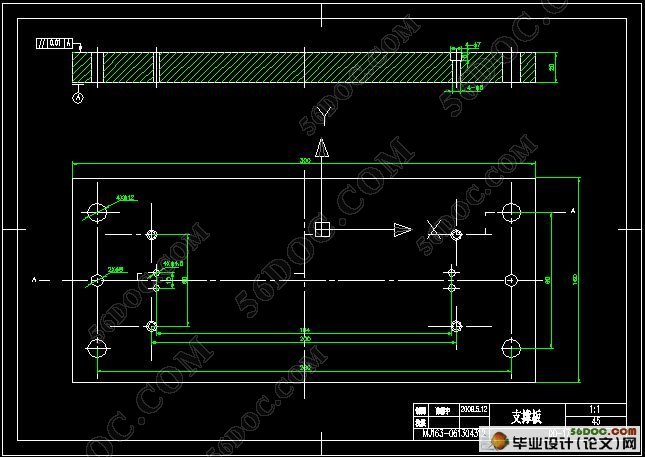

4.2定位零件的设计…………………………………………………………………13

5模具的装配调试……………………………………………………………………16

5.1冲裁模的装配调试要点…………………………………………………………17

5.3冲裁模试冲试冲时出现的问题及调整方法……………………………………18

5.4装配其他零件并试模……………………………………………………………19

6弯板冲孔落料复合模总装图………………………………………………………20

7弯曲模具装配图……………………………………………………………………21

8结束语………………………………………………………………………………22

致谢 …………………………………………………………………………………23

参考文献………………………………………………………………………………24