安装板冲压成形工艺及模具设计(附加工工艺卡)

无需注册登录,支付后按照提示操作即可获取该资料.

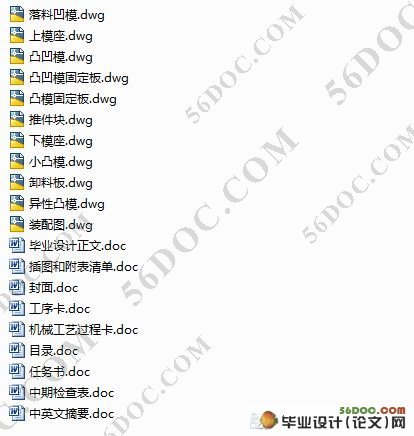

安装板冲压成形工艺及模具设计(附加工工艺卡)(含任务书,中期检查报告,毕业论文说明书11000字,cad图纸11张)

摘要

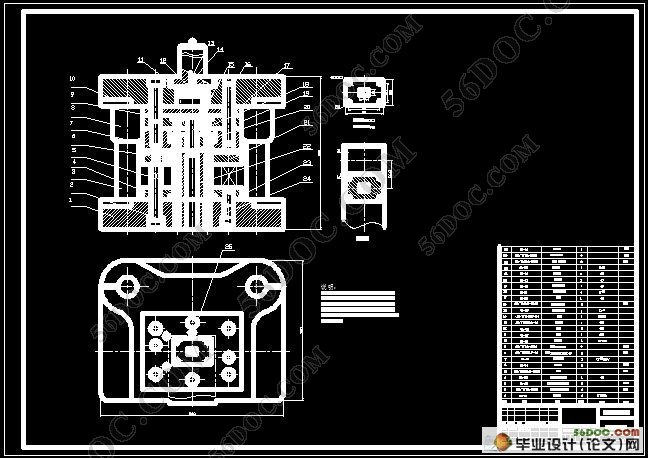

本设计为安装板冲孔落料复合模设计。通过对该零件模具的设计,进一步加强了设计者冲压模设计的基础知识,为设计更复杂的冲压模具做好了铺垫和吸取了更深刻的经验。

本设计运用冲压成形工艺及模具设计的基础知识,首先分析了冲压件的外形及用处性能要求,为选取模具的类型做好了准备;然后计算了冲压力,便于选取压力机;最后计算了制件的压力中心,确定模具的设计参数、设计要点及推出装置的选取。

设计复合模,首先要设计条件排样图。加强板的形状简单。由于零件外形尺寸为自由尺寸对精度要求不高,为了提高材料的利用率减少冲裁力,虽然这时会使零件外形尺寸公差等级降低但是经过筹兼顾,全面考虑。这里我们采用有废料排样。

凹模采用整体式凹模,各冲裁的凹模孔均采用线切割机床加工,安排凹模在模架上的位置时要依据计算压力中心与模柄中心重合。

关键词:复合模 、中批量 、安装板 、废料排样 、下出料方式、卸料板

Inforced Plate of The Stamping Die Design

Abstract

This is designed to strengthen the board blanking punching Progressive Die Design. Parts of the mold through the design, Further strengthen the designers of stamping die design of the basic knowledge. For the design of more complex stamping die to pave the way and the lessons more profound experience.

The design and use of stamping die design of the basic knowledge ,

First of stamping parts of the appearance and usefulness of performance requirements. To select the type of mold prepared for the Die Design design,Chong then calculate the pressure for selecting Press,The final calculation of the pressure on the central parts, the design parameters established mold, design elements and the introduction of the selected devices。

Progressive Die Design, first of all conditions to design layout plans. Strengthen the shape of a simple plate. As for the free parts Dimension size on the accuracy Yaoqiubugao, in order to increase the utilization of materials to reduce punching power, although at this time would spare parts Dimension tolerance levels but lower after chip into consideration and full consideration. Here, we use no waste nesting.

Die using integrated die, blanking the die-adopted WEDM processing, for die-shelf in the position should be calculated based on pressure center and center-stalk coincidence.

Keywords: Progressive Die、In bulk、Strengthen the board、Waste nesting、Under the expected way、Discharge plate

#p#副标题#e#

目录

1 绪论………………………………………………………………………………1

1.1 国内模具的现状和发展趋势…………………………………………………1

1.1.1国内模具的现状………………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………………3

1.2国外模具的现状和发展趋势……………………………………………………6

1.3 安装板模具设计与制造………………………………………………………7

1.3.1安装板模具设计的设计思路…………………………………………………7

1.3.2安装板模具的设计进度………………………………………………………8

2 安装板冲压工艺分析……………………………………………………………9

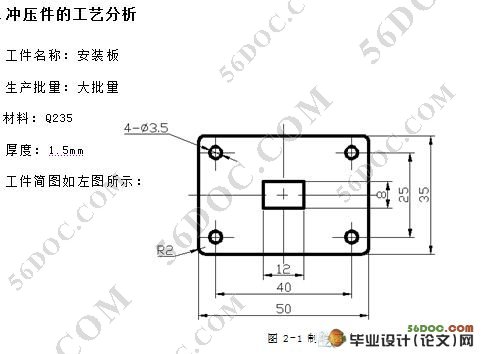

2.1 冲压件的工艺分析……………………………………………………………9

2.2 冲压工艺计算和工艺方案……………………………………………………9

2.2.1 工艺方案的确定………………………………………………………………9

2.2.2 必要的工艺计算………………………………………………………………10

3 模具的结构设计…………………………………………………………………16

3.1 模具总体设计…………………………………………………………………16

3.2模具主要零部件的结构设计……………………………………………………16

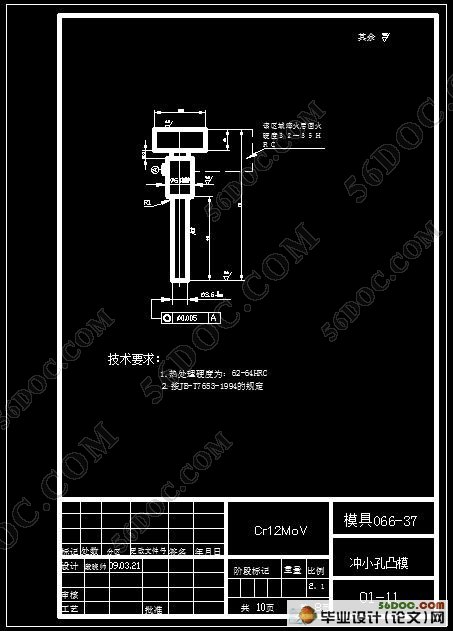

3.2.1凸模、凹模、凸凹模的结构设计………………………………………………16

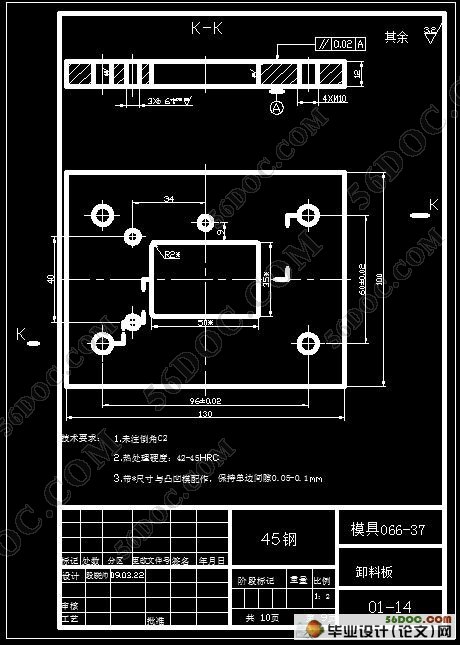

3.2.2卸料弹簧的结构设计……………………………………………………………19

3.2.3模架的设计………………………………………………………………………20

4 冲压设备的选择…………………………………………………………………22

5 结束语……………………………………………………………………………23

致谢 …………………………………………………………………………………24

参考文献………………………………………………………………………………25